Graphene composite slurry and heating coating thereof, and preparation methods thereof

A graphene composite and heating coating technology, applied in coatings, fire-retardant coatings, conductive coatings, etc., can solve problems such as limitations, insufficient electrical and thermal properties of graphene, and failure to develop graphene high-temperature far-infrared level. , to achieve the effect of low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

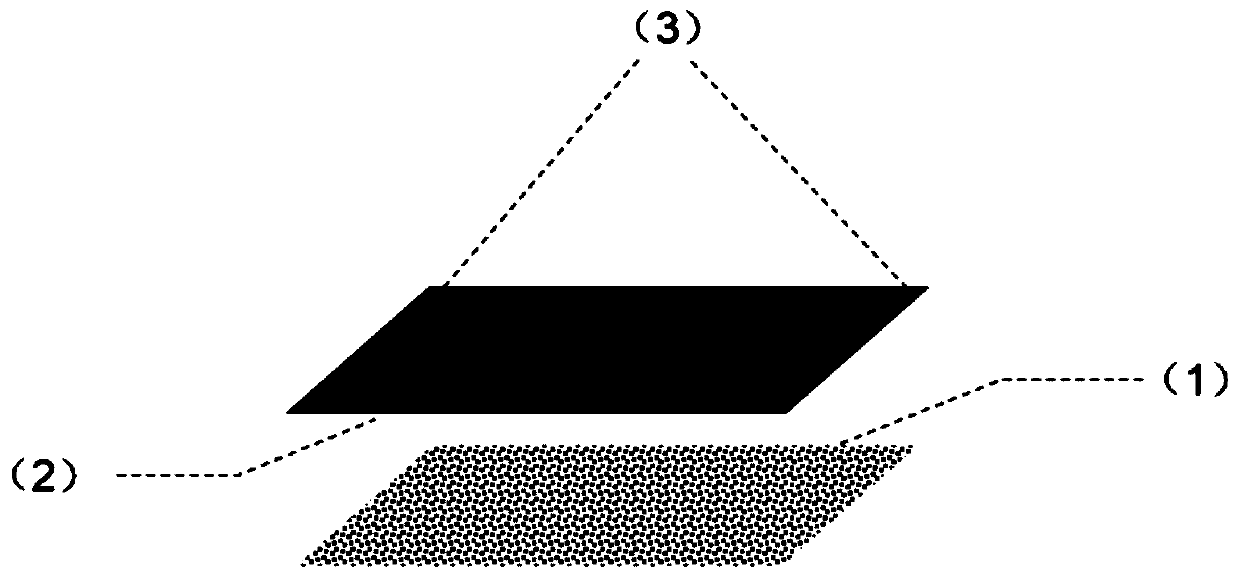

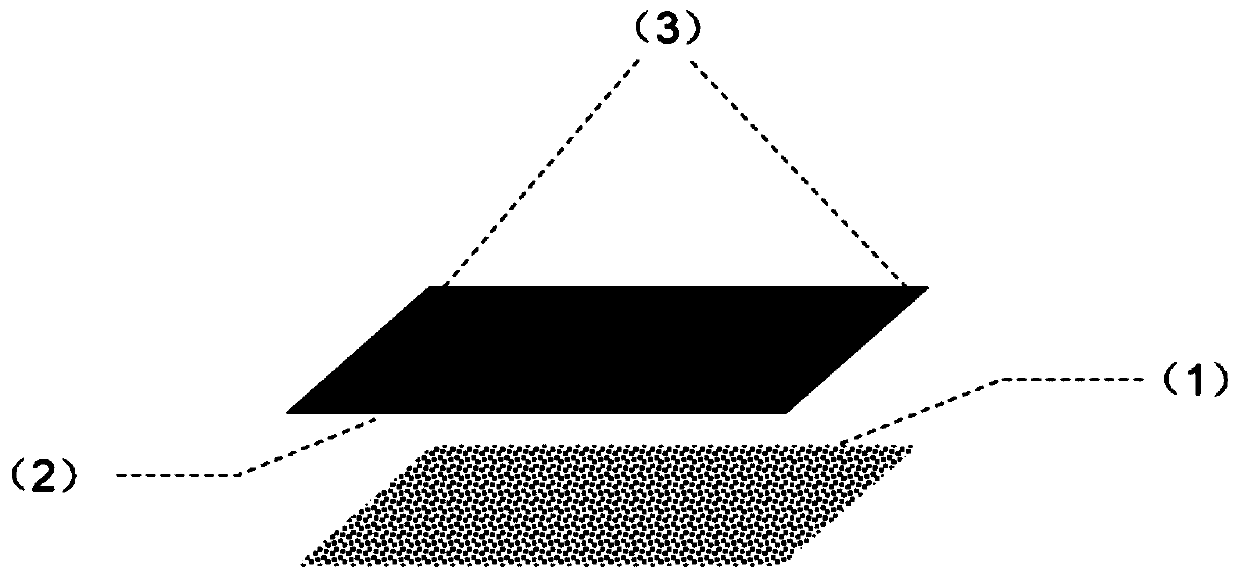

[0025] The technical solutions in the embodiments of the present invention will be described in detail below in combination with the drawings in the patent embodiments of the present invention. Apparently, the embodiment described in this implementation mode is only a general case of the content contained in the present invention, not all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without other creative work other than the claims of the present invention fall within the protection scope of the present invention.

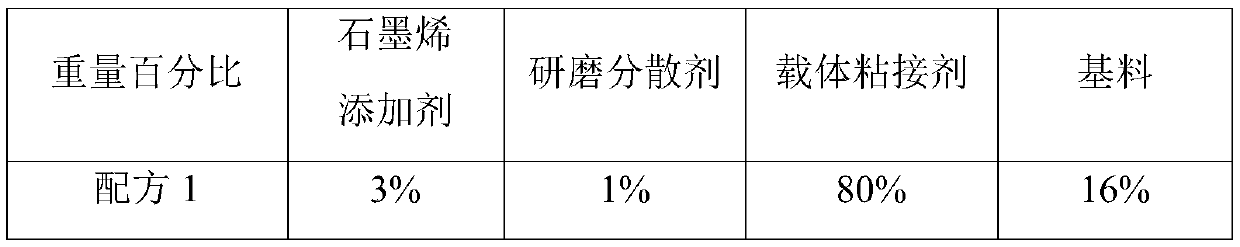

[0026] A graphene composite slurry of the present invention comprises a base material, a grinding dispersant, a carrier adhesive and a graphene additive, and the weight percentage of the base material in the graphene composite slurry is 16% to 70%, wherein the base material Contains: microsilica, alumina, ferric oxide, magnesia and chromium sesquioxide, wherein the percentage by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com