Stainless steel foil and preparation method thereof

A technology of stainless steel foil and stainless steel strip, which is applied in the field of solar cells, can solve problems such as hardness reduction, stainless steel foil wrinkles, solar cell productivity, and photoelectric conversion efficiency reduction, and achieve good board passability and the effect of suppressing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

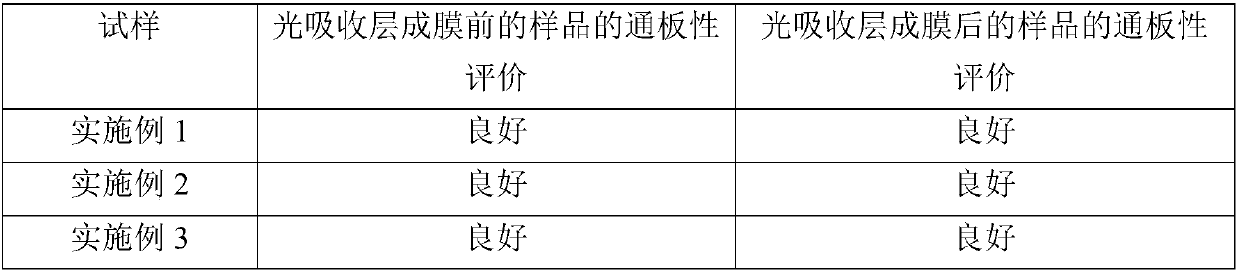

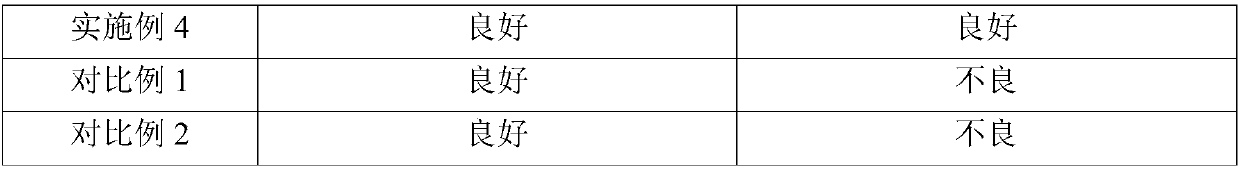

Examples

Embodiment 1

[0026] A kind of stainless steel foil provided by the present invention comprises the following components by weight percentage:

[0027] C: 0.20wt%, Si: 2.5wt%, Mn: 1.2wt%, Cr: 10.0wt%, P: ≤0.003wt%, S: ≤0.001wt%, Ni: 0.15wt%, N: 0.08wt%, C+N: 0.28wt%, Al: 0.1wt%, O: ≤0.006wt%, Nb: 0.65wt%, Ti: 0.65wt%, Nb / Ti=1.0, Mo: 2.1wt%, the rest is Fe and not Avoided impurities, the total amount of which is less than 0.01 wt%.

[0028] Use converters, electric furnaces, etc. to melt the steel containing the above composition, and use VOD (Vacuum oxygen decarburization, vacuum oxygen decarburization) and AOD (Argon oxygen decarburization, argon oxygen decarburization) for secondary refining, and then use ingot-opening Stainless steel strip is made by rolling method or continuous casting method.

[0029] The manufacturing process of manufacturing stainless steel foil from a stainless steel strip in this example is substantially the same as the manufacturing process of ordinary stainless...

Embodiment 2

[0039] A kind of stainless steel foil provided by the present invention comprises the following components by weight percentage:

[0040] C: 0.22wt%, Si: 2.8wt%, Mn: 1.4wt%, Cr: 13.0wt%, P: ≤0.003wt%, S: ≤0.001wt%, Ni: 0.25wt%, N: 0.08wt%, C+N: 0.3wt%, Al: 0.2wt%, O: ≤0.006wt%, Nb: 0.85wt%, Ti: 0.75wt%, Nb / Ti=1.13, Mo: 2.3wt%, the rest is Fe and not Avoided impurities, the total amount of which is less than 0.01 wt%.

[0041]The steel containing the above components is smelted using a converter, an electric furnace, etc., and subjected to secondary refining using VOD and AOD, and then made into a stainless steel strip by ingot casting-slab rolling or continuous casting.

[0042] The manufacturing process of manufacturing stainless steel foil from a stainless steel strip in this example is substantially the same as the manufacturing process of ordinary stainless steel foil. That is, a stainless steel strip is foil-rolled, then surface-washed, final annealed, and if necessary,...

Embodiment 3

[0051] A kind of stainless steel foil provided by the present invention comprises the following components by weight percentage:

[0052] C: 0.21wt%, Si: 3.3wt%, Mn: 1.3wt%, Cr: 12.0wt%, P: ≤0.003wt%, S: ≤0.001wt%, Ni: 0.20wt%, N: 0.09wt%, C+N: 0.30wt%, Al: 0.15wt%, O: ≤0.006wt%, Nb: 0.81wt%, Ti: 0.71wt%, Nb / Ti=1.14, Mo: 2.0wt%, the rest is Fe and not Avoided impurities, the total amount of which is less than 0.01 wt%.

[0053] The steel containing the above components is smelted using a converter, an electric furnace, etc., and subjected to secondary refining using VOD and AOD, and then made into a stainless steel strip by ingot casting-slab rolling or continuous casting.

[0054] The manufacturing process of manufacturing stainless steel foil from a stainless steel strip in this example is substantially the same as the manufacturing process of ordinary stainless steel foil. That is, a stainless steel strip is foil-rolled, then surface-washed, final annealed, and if necessa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com