Anti-falling concrete floorslab, connection joint and construction method for anti-falling concrete floorslab

A concrete and anti-fall technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of reducing the effective height of the end of the plate, the bending resistance of the end of the plate, and the damage of the node area, so as to reduce the weight and improve the force transmission. The effect of high efficiency and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

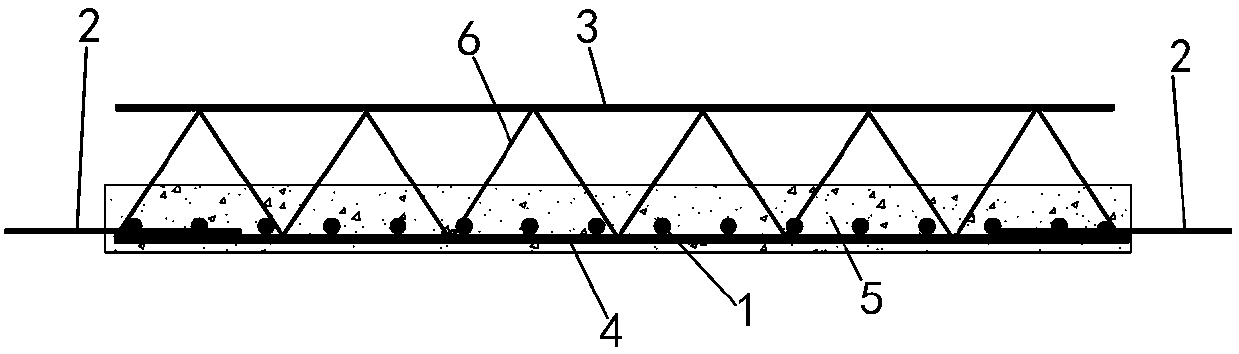

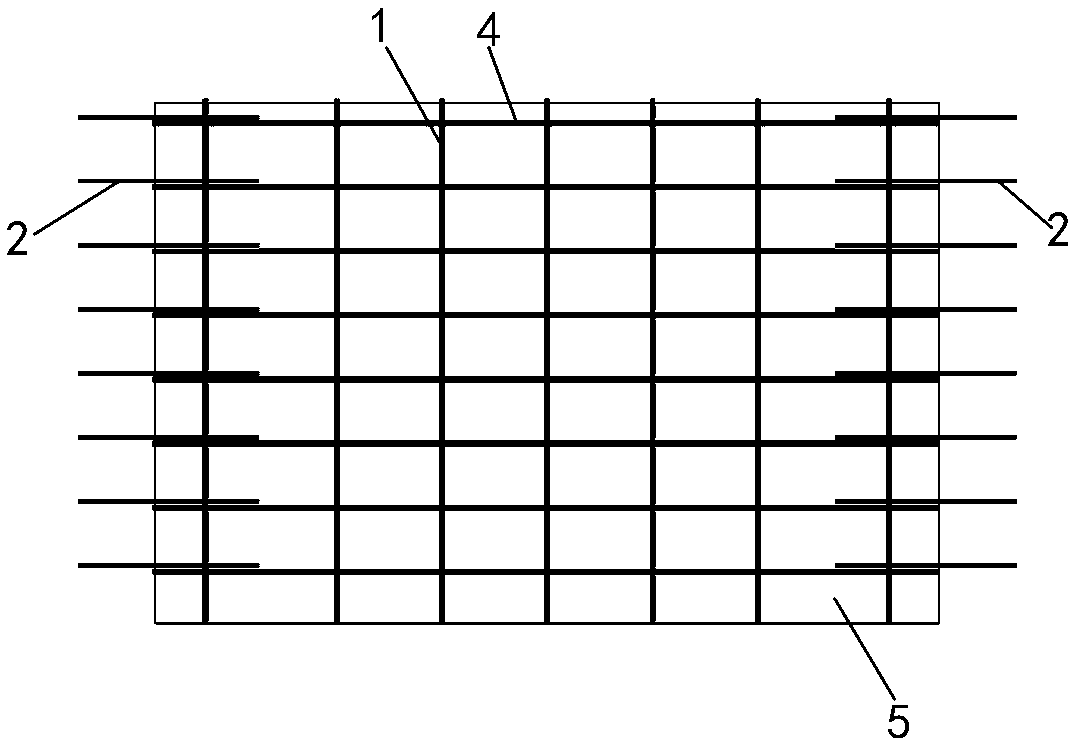

[0091] Embodiment one sees figure 1 and image 3 shown.

[0092] An anti-fall concrete floor slab, comprising a slab body, the slab body includes a prefabricated part, the prefabricated part includes a concrete base plate 5 on the lower side and a steel component of the prefabricated part, and the steel component of the prefabricated part includes a steel bar truss and a lower transverse steel bar 1 and lower strand anchor 2.

[0093] The steel bar truss comprises a longitudinal truss upper bar 3, a longitudinal truss lower bar 4 and a truss web bar connecting the two, the truss lower bar 4 is located in the concrete substrate, and the lower horizontal steel bar is fixedly connected with the truss lower bar 4 to form The lower layer of steel mesh.

[0094] The truss upper rib 3 is parallel to the truss lower rib 4, the truss upper rib 3 is located above the concrete substrate 5, the truss upper rib 3 and the truss lower rib 4 are connected by the truss web 6, the bottom of ...

Embodiment 2

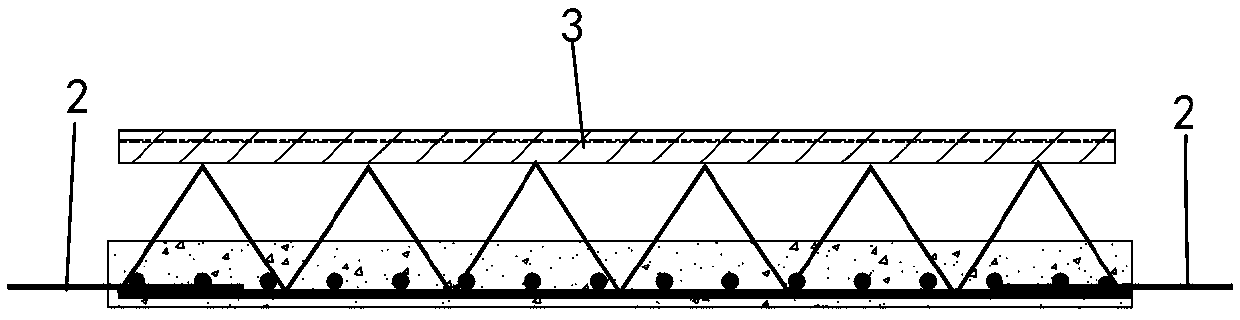

[0102] Embodiment two see figure 2 and image 3 shown.

[0103] Different from the first embodiment, the upper rib 3 of the truss in the second embodiment is a steel member.

Embodiment 3

[0104] Embodiment three is shown in 4.

[0105] The difference from Embodiment 1 is that the part of the lower steel strand anchor 2 protruding from the concrete substrate 5 is a ferrule, which is a U-shaped steel strand, and the two legs of the steel strand are respectively fixedly connected to the adjacent Between the lower ribs 4 of the two trusses, the opening of the ferrule faces inward.

[0106] The construction method of above embodiment anti-falling concrete floor, construction steps are as follows:

[0107] Step 1: The factory manufactures the steel components of the prefabricated part.

[0108] Step 2, supporting the formwork of the floor slab.

[0109] Step 3, laying steel trusses, lower steel strand anchors 2 and lower horizontal reinforcement.

[0110] Step 4: Pouring concrete to form the concrete substrate 5 .

[0111] Step five, curing the concrete to the predetermined strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com