Precast hollow superimposed shear wall based on flat die production and steel bar overlapping

A technology for superimposing shear walls and prefabricated walls, applied in the direction of walls, building materials, building components, etc., can solve the difficulty in realizing the integrated construction of prefabricated exterior wall structure, thermal insulation and decoration, imperfect on-site supporting construction technology, and restricting promotion. Application and other issues, to achieve the effect of standardization and generalization of molds, avoiding fixed equipment investment, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

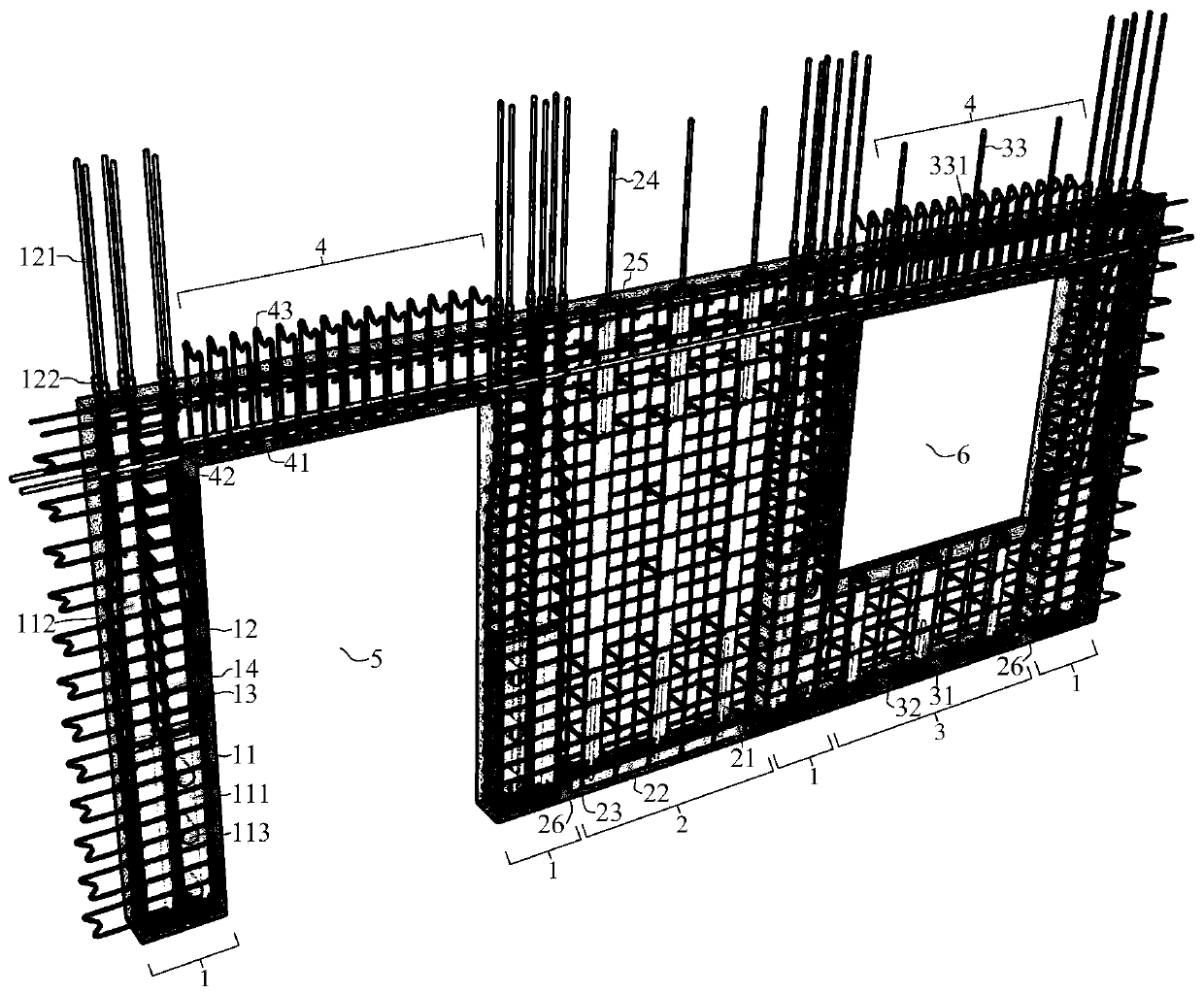

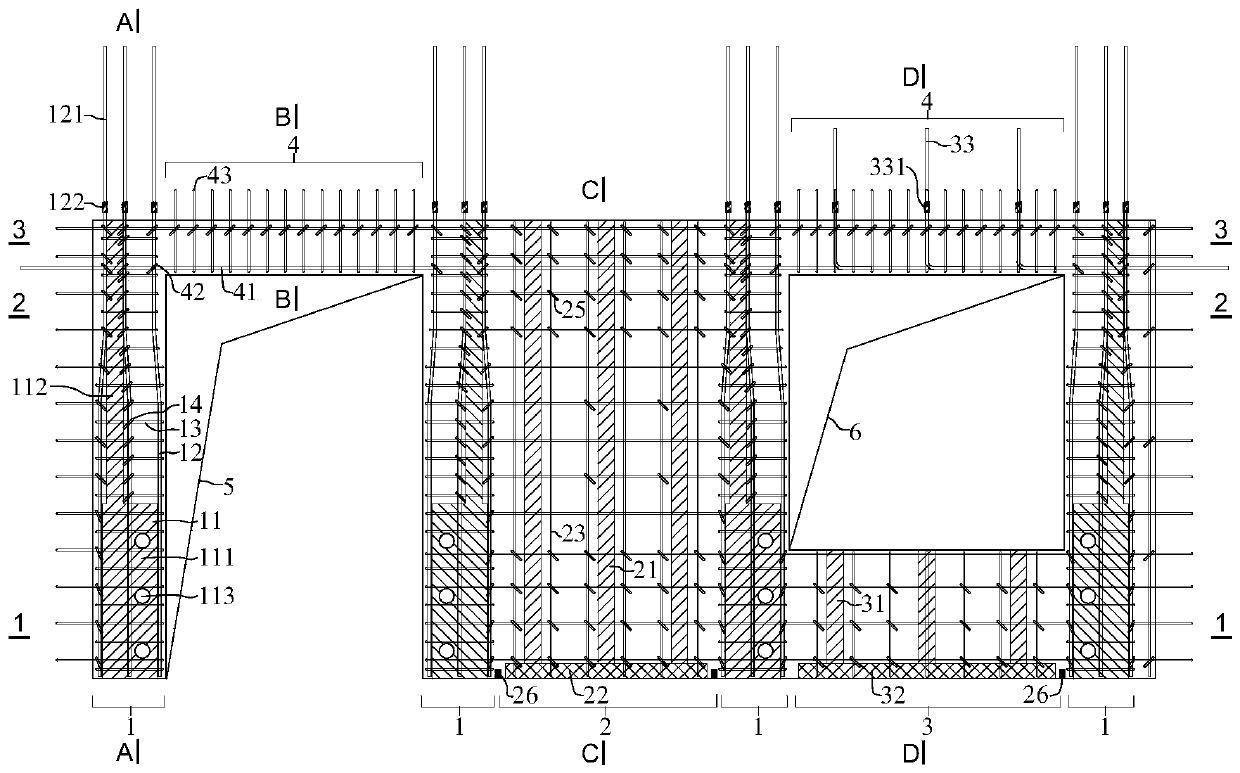

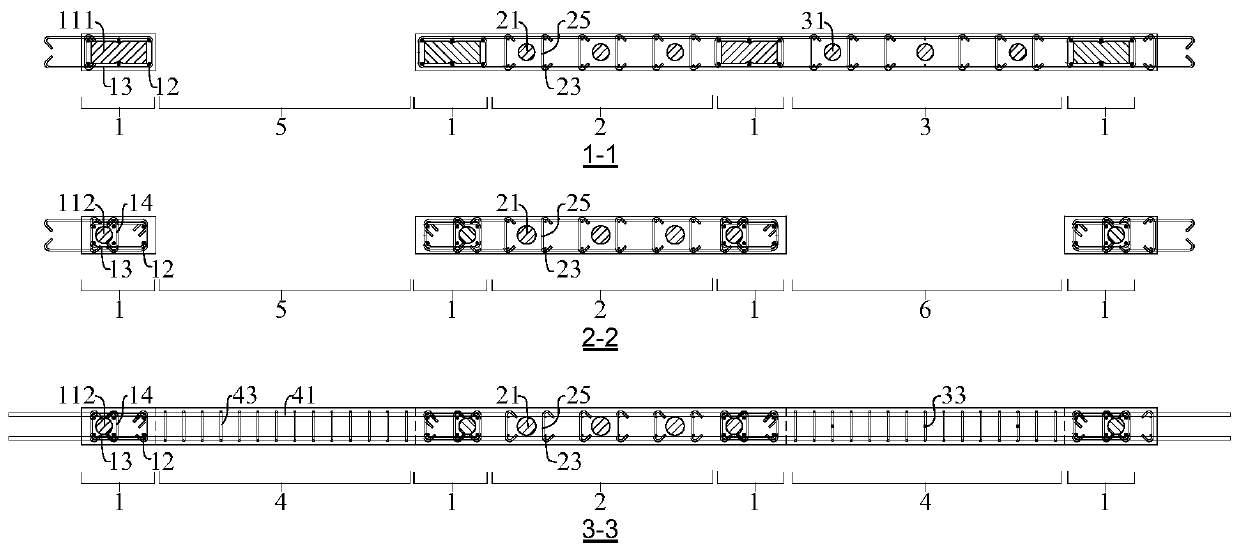

[0067] Such as Figure 1 to Figure 7 As shown, in this embodiment, the prefabricated hollow laminated shear wall includes an edge member area 1 , a wall body area 2 , a window wall area 3 , a coupling beam area 4 , a door opening 5 and a window opening 6 . It should be noted that the edge member area 1 and the wall body area 2 can be independently used for the prefabricated hollow laminated shear wall based on flat mold production and steel bar lapping according to the present invention. The specific embodiment is to more fully illustrate the scheme of the present invention, including the wall area 3 under the window, the connecting beam area 4, the door opening 5 and the window opening 6, but it does not represent the prefabricated hollow lamination based on the production of flat molds and the overlapping of steel bars in the present invention The shear wall must be used for the prefabricated shear wall including the wall area 3 under the window, the coupling beam area 4, th...

Embodiment 2

[0084] Figure 14 ~ Figure 18 Shown is the second embodiment of the present invention, which differs from the preferred embodiment one in that the position of the edge member adopts two small-sized edge member holes to form two vertical holes with a shaping pipe 11, so as to realize the vertical The advantage of the lap joint connection of steel bars is that during flat die production, the space between the two small-sized edge member hole forming pipes 11 is more helpful to ensure the pouring quality of the lower part of the concrete, and facilitates the rowing of the edge member tie bars 14. cloth. The shaped pipe 11 for forming a hole in a single small-sized edge member is also composed of a lower pipe 111 and an upper pipe 112 . Wherein the length of the lower pipe 111 should not be less than the lap length of the vertical reinforcement of the edge member, the cross section adopts a rectangular cross section, and the four corners are bent to form a chamfer to avoid the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com