Tunnel concrete lining inflation mold

A technology of concrete and mould, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of high cost, heavy weight, long cycle and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the drawings and embodiments.

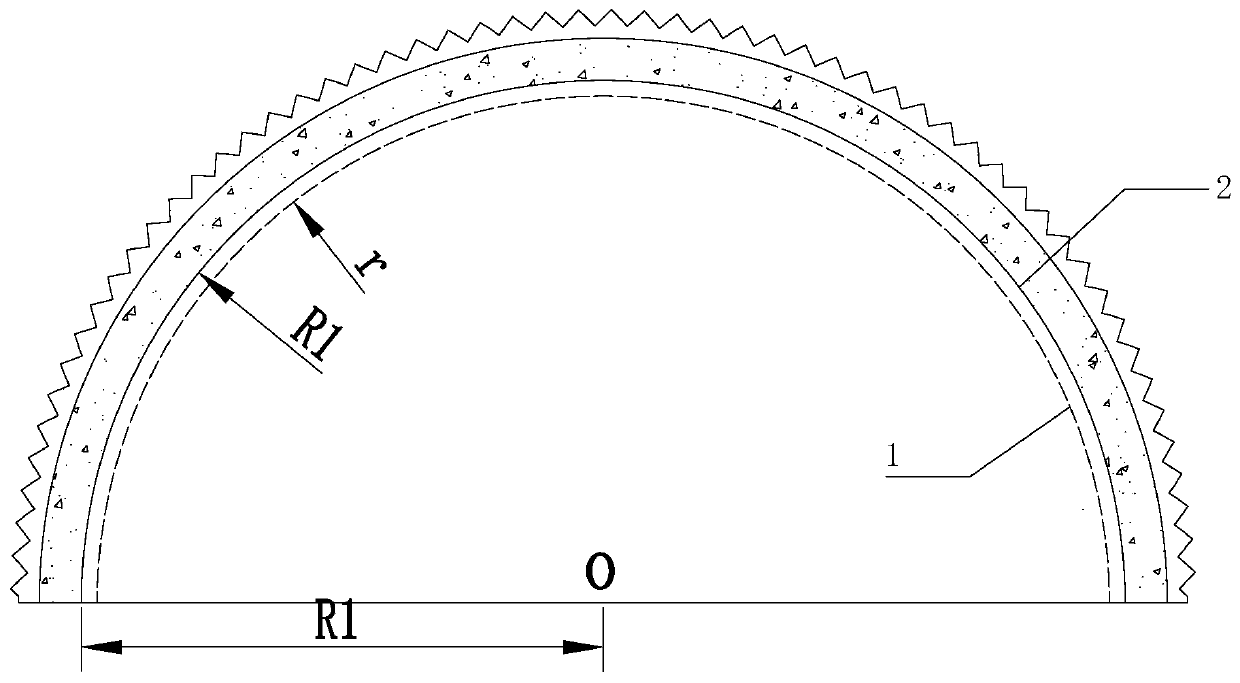

[0017] reference Figure 1-Figure 4 , An inflatable mold for tunnel concrete lining, comprising: an inner tube 1 and an outer tire 2 arranged concentrically, the diameter of the outer tire 2 is the same as the radius after the tunnel is lined, and the radius of the inner tire 1 is smaller than the radius of the outer tire 2;

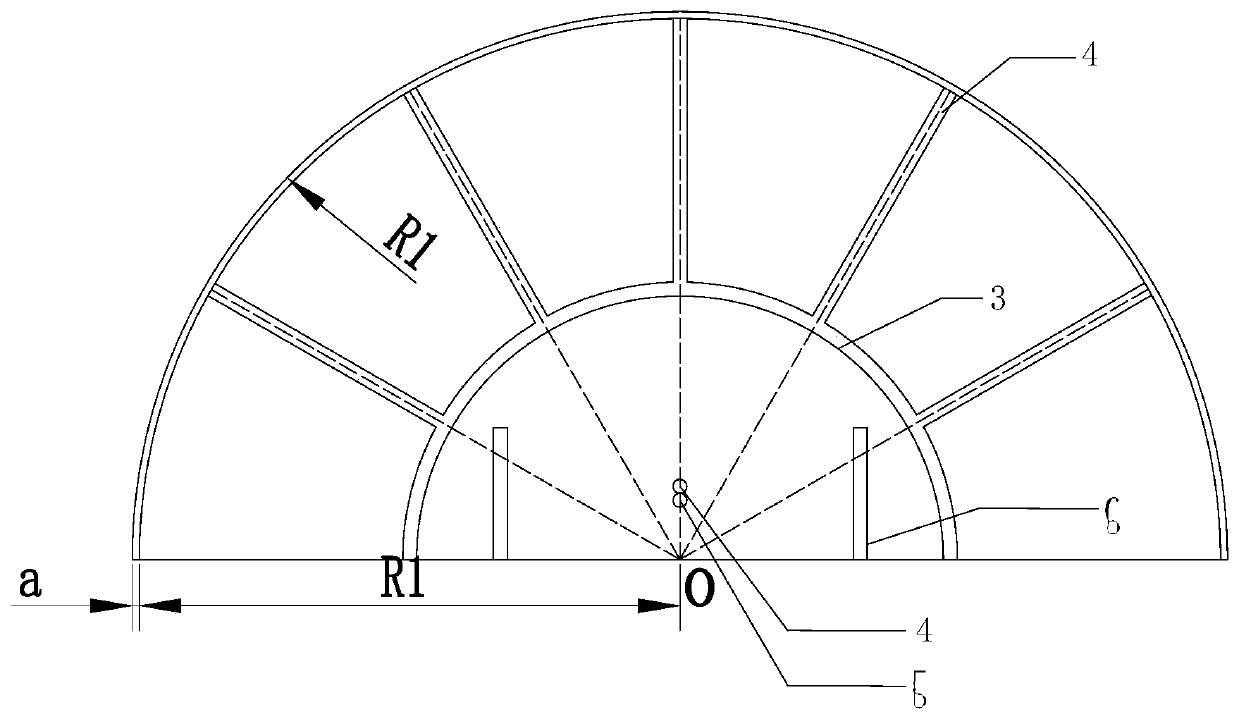

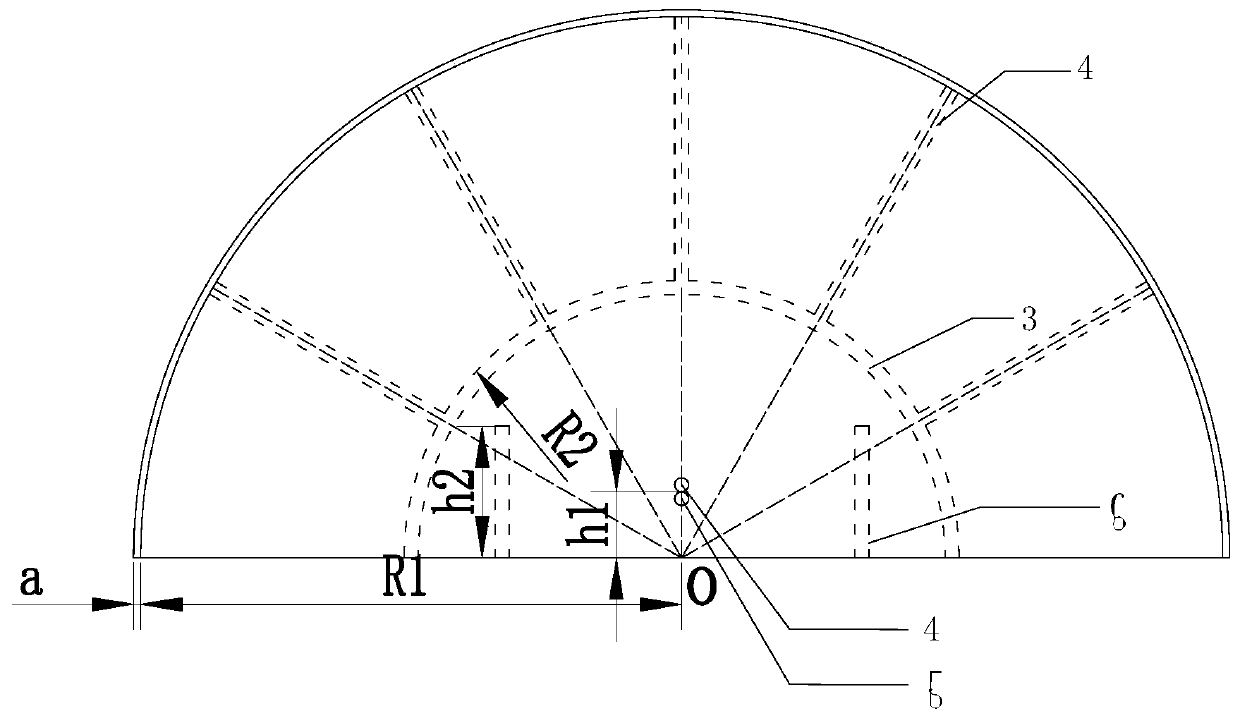

[0018] It also includes a stiffening rib. The stiffening rib includes a first part 3 arranged concentrically with the inner tube 1 and a second part 4 extending in the radial direction; the first part 3 is arranged inside the inner tube 1, and the second part 4 is connected to Between the first part 3 and the inner tube 1;

[0019] The inflatable mold is further provided with an inflatable hole 4, a connecting hole 5, and a fixed pile groove 6 on the inner side of the first part 3; the inflatable hole 4 is connected to the inner tube 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com