Diaphragm compressor oil path system and cleaning method of oil path system

A diaphragm compressor, oil circuit system technology, applied in mechanical equipment, machinery/engine, liquid variable capacity machinery, etc., to achieve the effect of good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

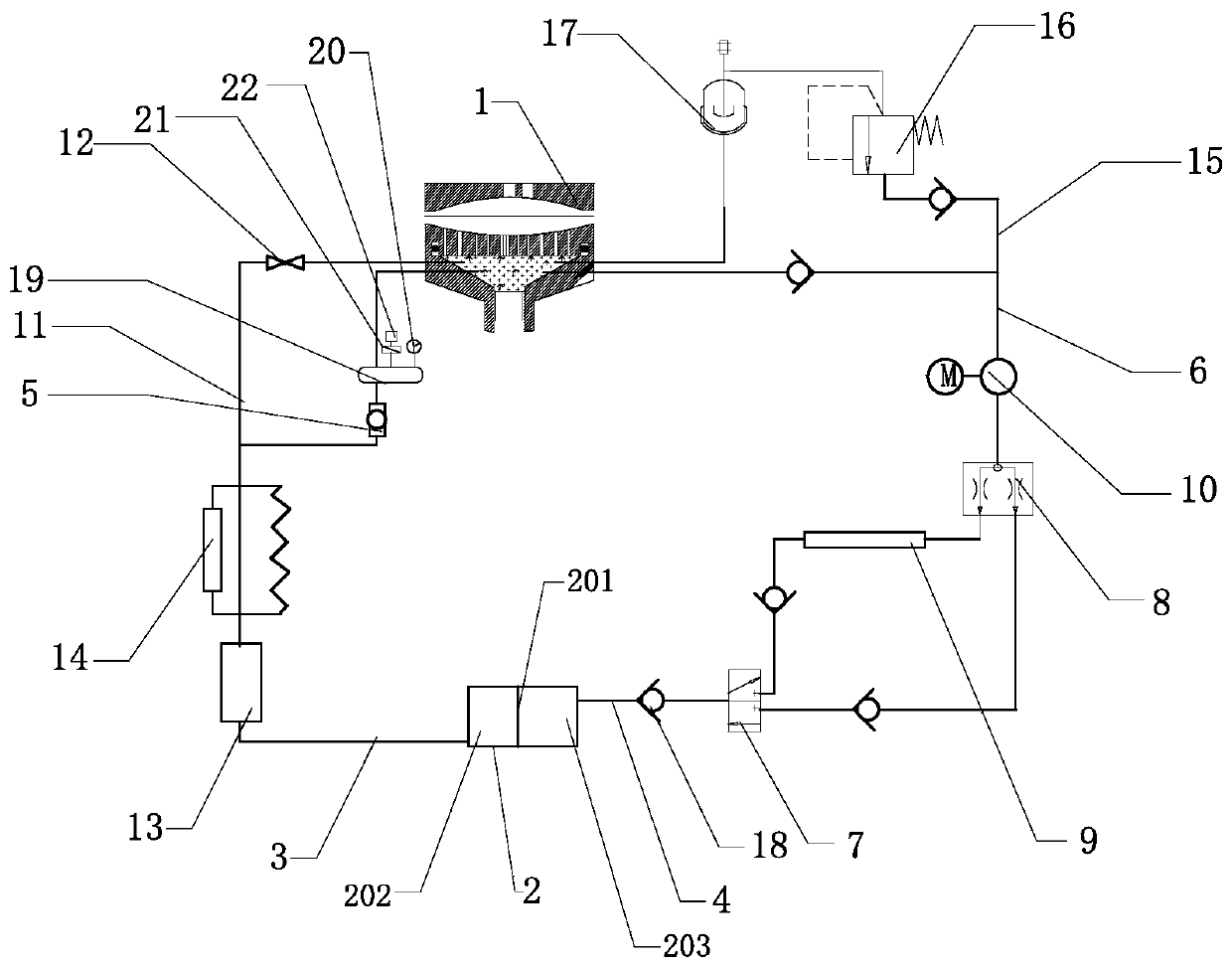

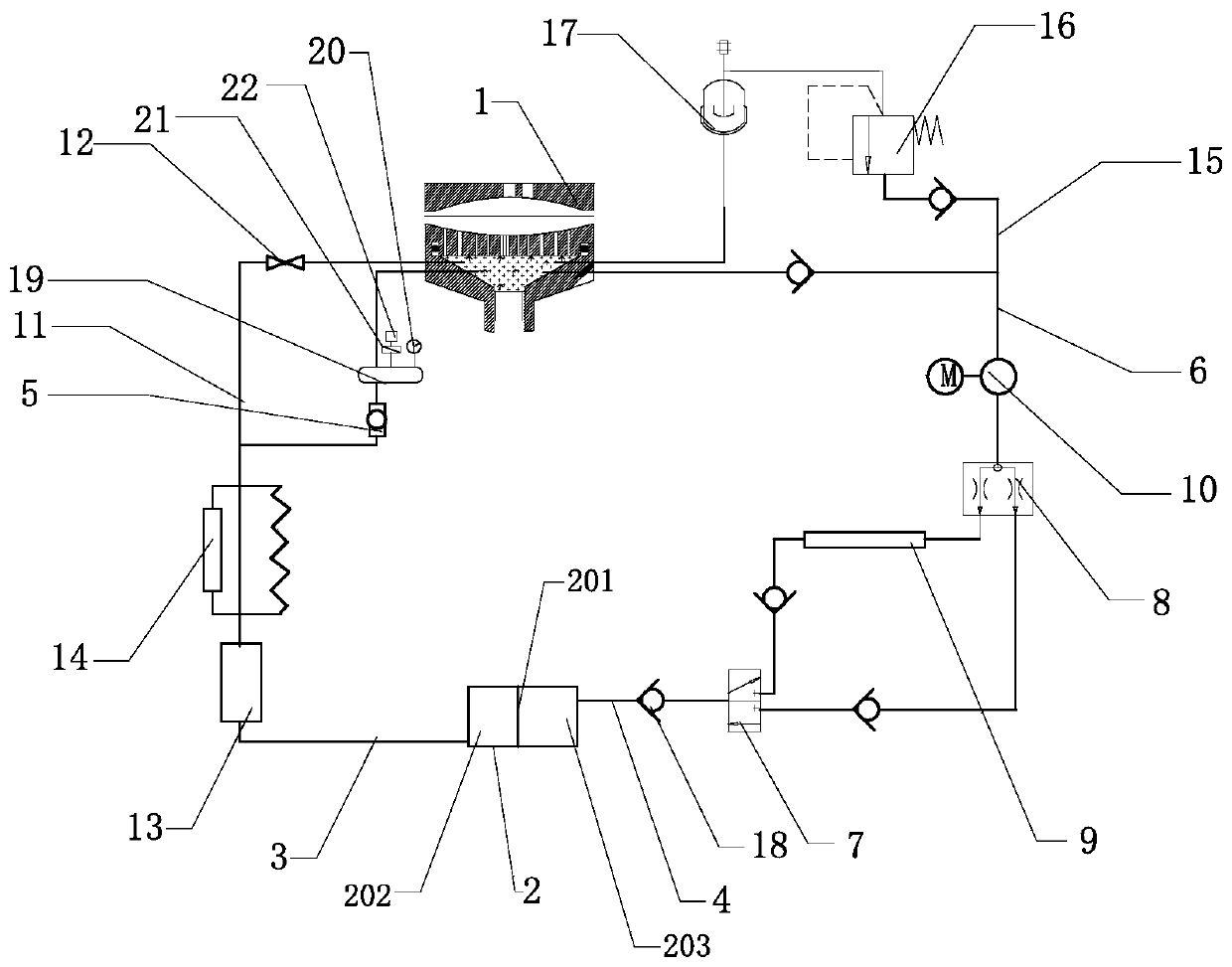

[0041] Such as figure 1 As shown, the present invention is a diaphragm compressor oil circuit system, including an oil cylinder 1 and an oil tank 2, an oil return pipeline 3 and an oil supply pipeline 4 are connected between the oil cylinder 1 and the oil tank 2, and an oil delivery pipeline 6 is also included , the oil pipeline 6 is provided with a temperature control valve 7 and a three-way valve 8 in sequence, the input end of the temperature control valve 7 communicates with the oil tank 2 through the oil supply pipeline 4, and the two outputs of the temperature control valve 7 The ends are respectively communicated with the two input ends of the three-way valve 8 through pipelines, and a cooler 9 is connected to one of the pipelines, and the output end of the three-way valve 8 is connected with an oil pump 10 through a pipeline, and the oil pump 10 It is connected to the oil cylinder 1 through a pipeline and delivers hydraulic oil for the oil cylinder 1; it also includes ...

Embodiment 2

[0045] This embodiment is a further description of the present invention.

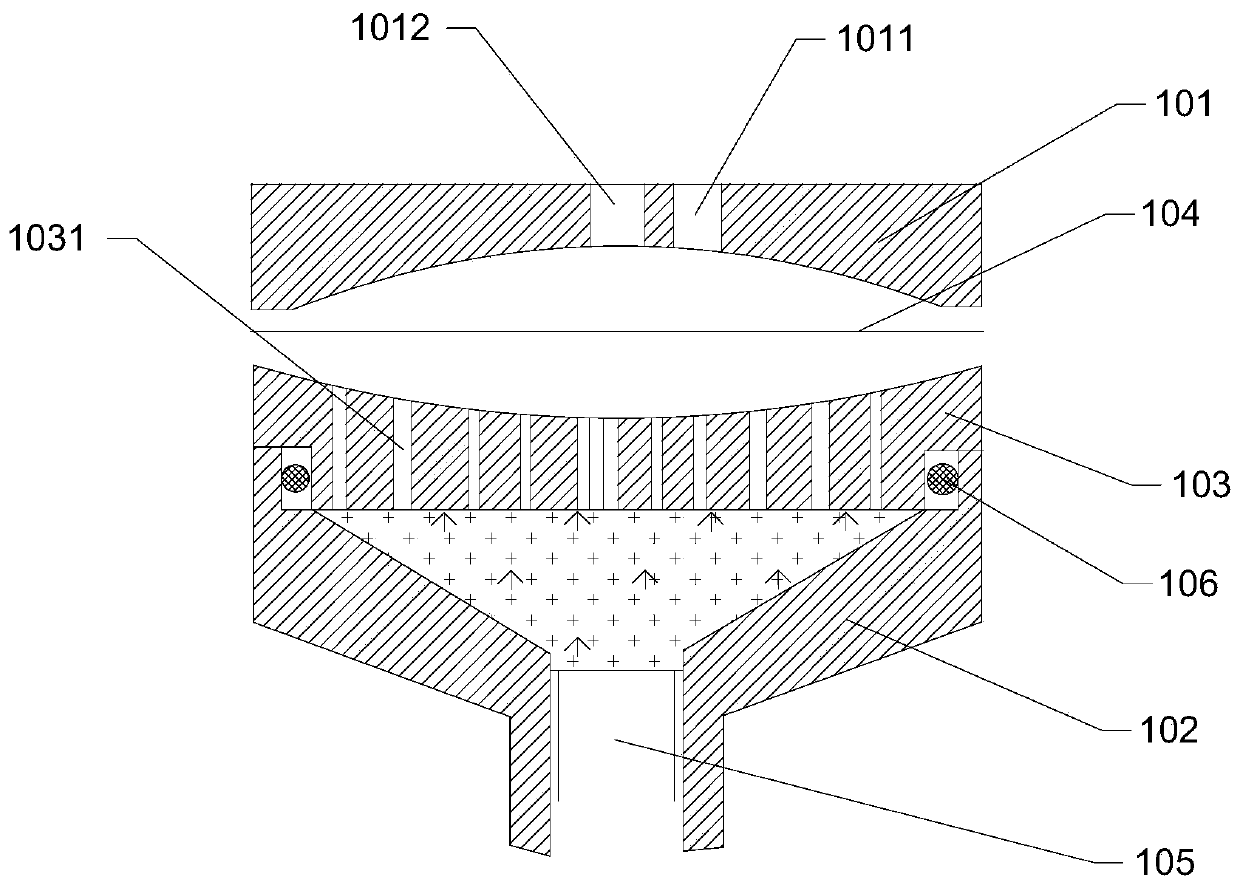

[0046] Such as figure 2 As shown, this embodiment is based on Embodiment 1. In a preferred embodiment of the present invention, the oil cylinder 1 includes a cylinder head 101, a cylinder body 102, an oil distribution plate 103, a diaphragm 104, a piston 105 and a sealing ring 106, the cylinder head 101 is provided with an air intake hole 1011 and an exhaust hole 1012, and the exhaust hole 1012 is arranged at the center of the cylinder head 101, and the oil distribution plate 103 is evenly distributed with oil groove holes 1031, the distribution The oil pan 103 is arranged on the upper end of the cylinder block 102, and a sealing ring 106 is arranged between the two. A curved surface groove is arranged on the cylinder head 101 and the oil distribution pan 103, and the cylinder head 101 and the oil distribution pan 103 form a cavity to Diaphragm 104 is clamped in the middle to form an air chamber and ...

Embodiment 3

[0048] This embodiment is a further description of the present invention.

[0049] Such as figure 1 As shown, this embodiment is based on Embodiment 1. In a preferred embodiment of the present invention, a decompression pipeline 15 is also included, and a decompression valve 16 and a constant pressure valve 16 are connected to the decompression pipeline 15. One end of the decompression pipeline 15 is connected to the oil pump 10, and the other end is connected to the oil cylinder 1 through the decompression valve 16 and the constant pressure device 17 in sequence. When the pressure in the oil supply pipeline 4 and the oil delivery pipeline 6 is too high, the hydraulic oil can be decompressed through the pressure reducing valve 16 in the decompression pipeline 15, and the hydraulic oil is supplied to the oil cylinder 1 to prevent the pressure of the oil delivery pipeline 6 from being too high Damage to the oil circuit system ensures the good lubrication effect of the diaphragm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com