Eccentric connecting rod type radial variable plunger pump

A variable plunger and eccentric connecting rod technology, applied in pumps, pump control, multi-cylinder pumps, etc., can solve the problems of reduced frictional resistance efficiency, difficulty in adjusting eccentricity, eccentric wear of plunger radial force, etc., to achieve reduction Eccentric wear phenomenon, the displacement adjustment mechanism is simple and compact, and the effect of avoiding radial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

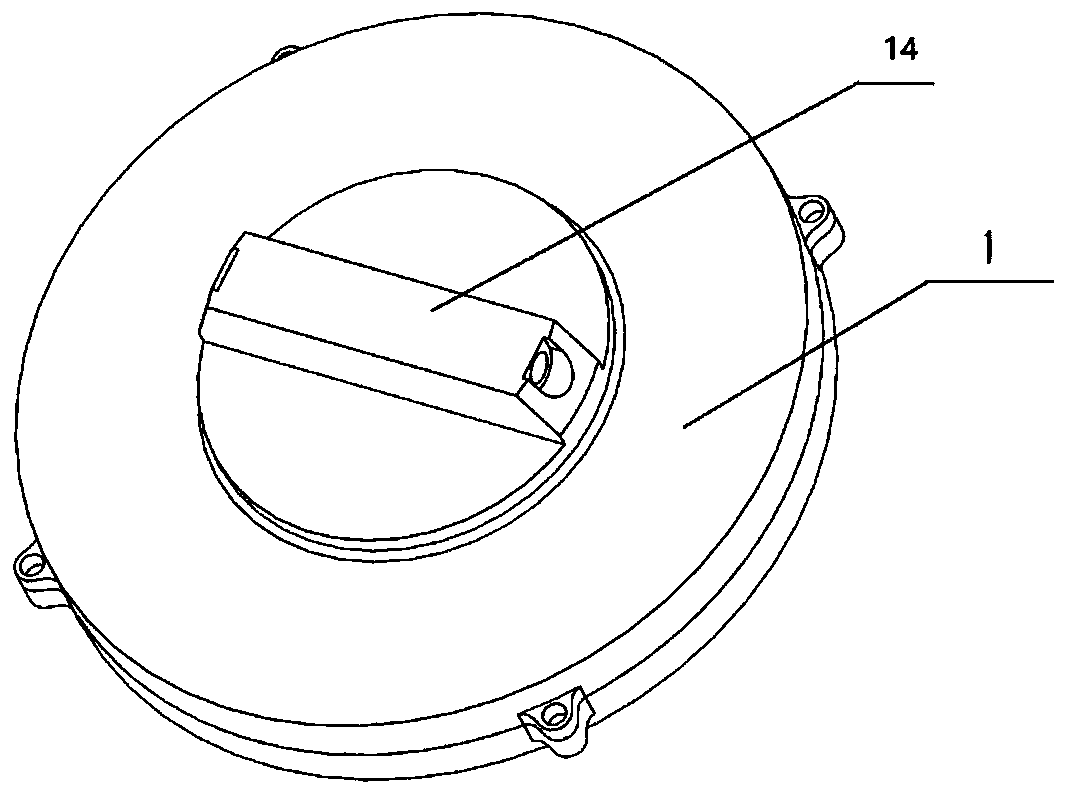

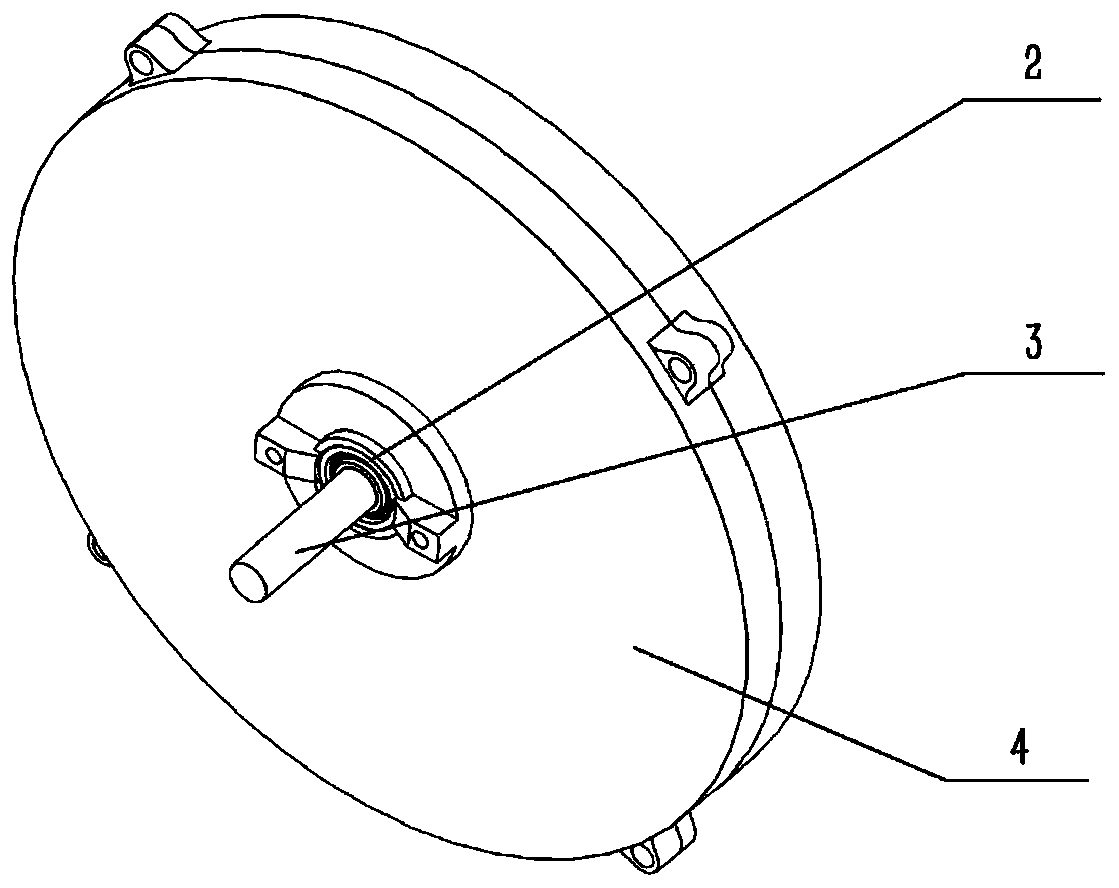

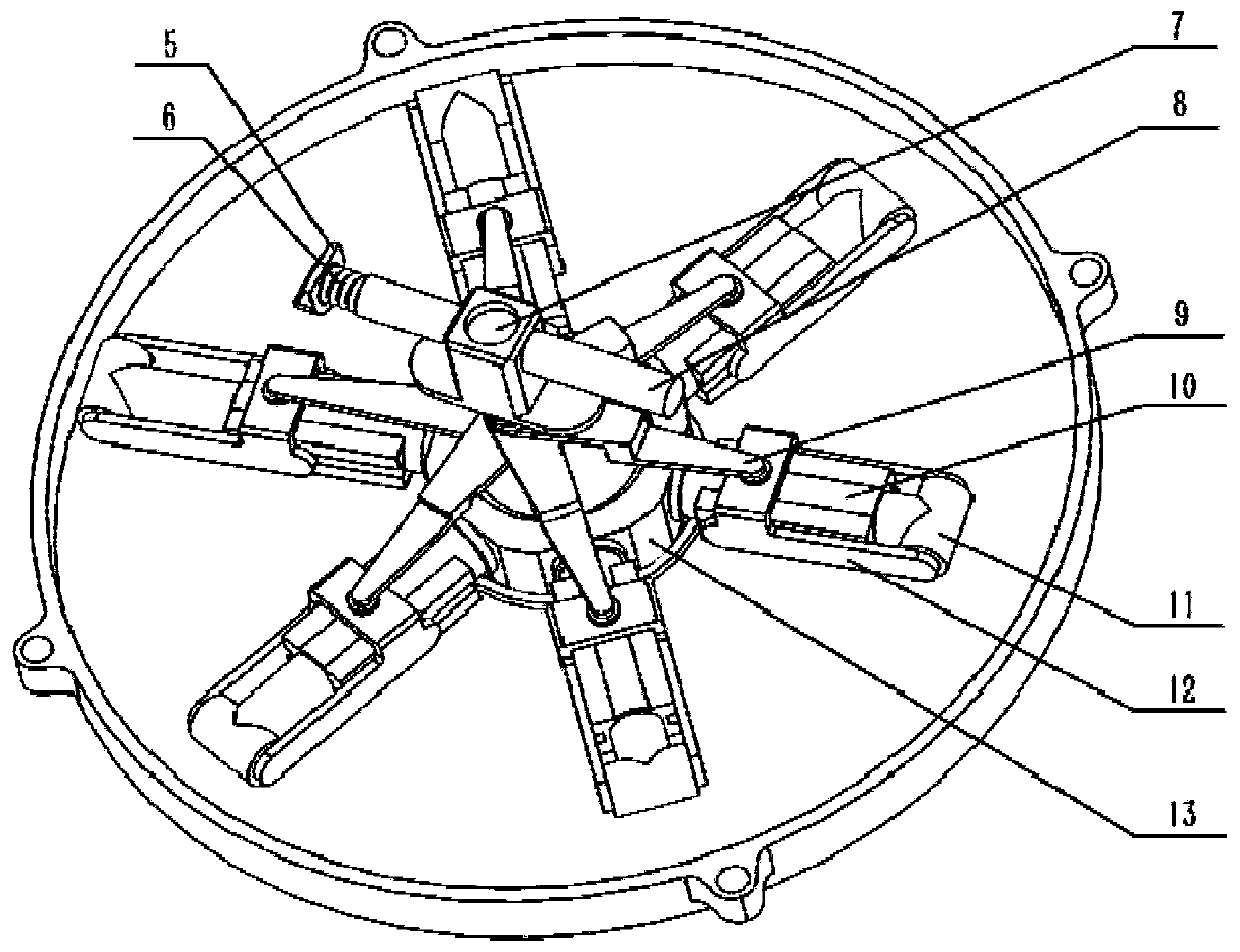

[0024] see figure 1 and image 3 , the present invention includes an upper shell 1 and a lower shell 4, a pump body is arranged in the cavity between the upper shell 1 and the lower shell 4; a valve cavity 14 is arranged on the upper shell 1, and an end cover 5 is fixed at one end of the valve cavity 14, The valve core 8 is placed in the valve chamber 14, and the valve core 8 is used to receive external hydraulic oil. The upper shell 1 and the lower shell 4 are combined and fastened by bolts. The top of the upper shell 1 is equipped with an integrated hydraulic control slide valve, the valve core 8 is installed in the valve cavity of the integrated hydraulic control slide valve, and the bearing hole in the lower shell 4 Two waist-shaped flow distribution grooves are arranged on the periphery, and the two flow distribution grooves communicate with the oil inlet hole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com