Waste gas treatment device for activated carbon fiber production workshop

A waste gas treatment device and activated carbon fiber technology, which is applied in the direction of air quality improvement, combustion methods, lighting and heating equipment, etc., can solve problems such as polluted environment, respiratory system damage, temporary cure, etc., to save energy, reduce environmental pollution, Effect of reducing damage to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

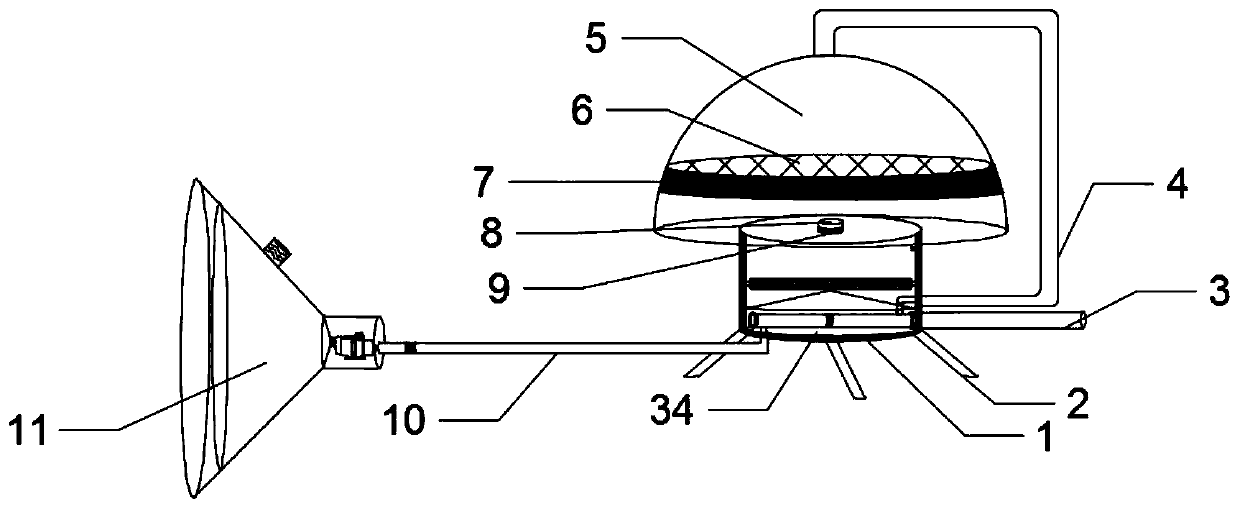

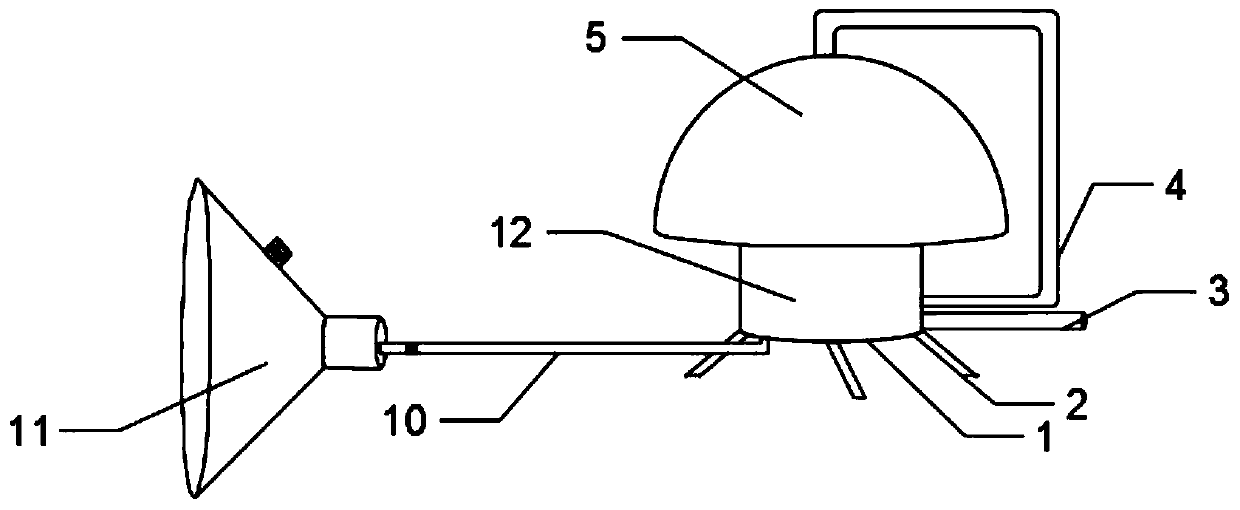

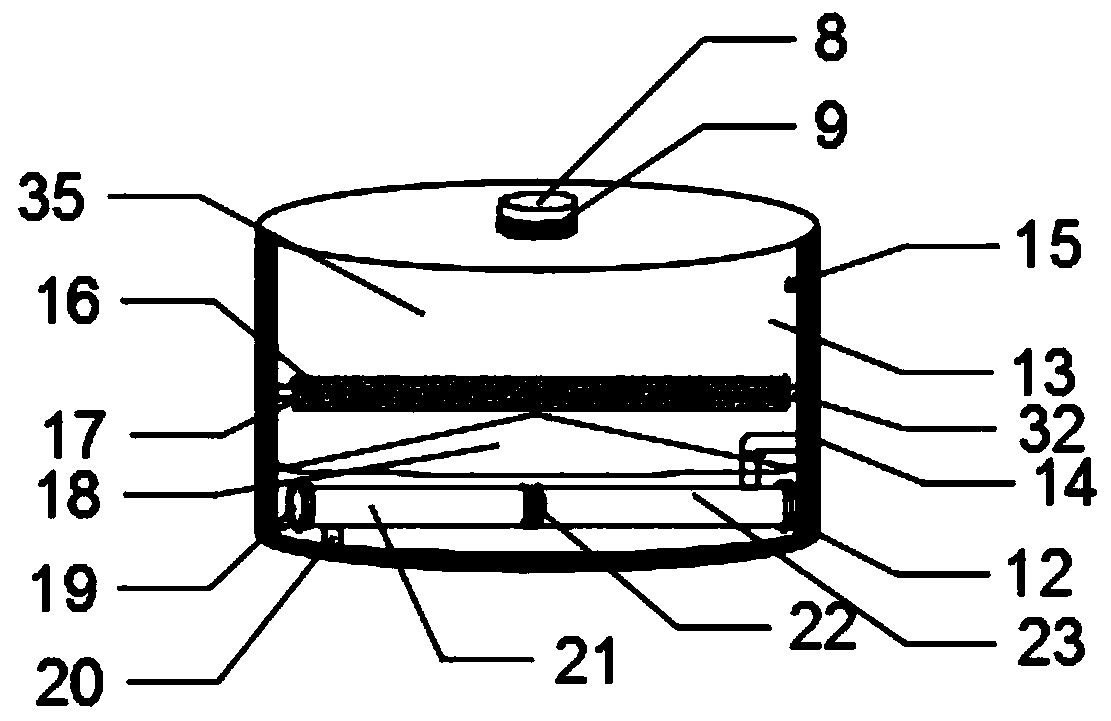

[0025] Such as Figure 1-Figure 6 As shown, the exhaust gas treatment device for the activated carbon fiber production workshop provided in this embodiment includes a base body 1 and a catalytic reaction chamber 5 installed above the base body 1. One side of the base body 1 is provided with a first filter connected by a first gas delivery pipe 10. Box 11, the base body 1 includes a second filter box 12 and an inner container 13 installed inside the second filter box 12, a preheating chamber 34 is provided inside the inner container 13, and a combustion chamber 35 is provided above the preheating chamber 34 to catalyze The interior of reaction chamber 5 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com