Reagent needle liquid taking process control method and system of medical instrument

A medical instrument and process control technology, applied in the field of medical devices, can solve problems such as liquid hanging, inaccurate liquid level detection, and long running time of reagent needles, so as to improve accuracy, save running time, and reduce the possibility of liquid hanging at the needle tip sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a method for controlling the process of taking liquid from a reagent needle of a medical instrument, including:

[0064] 1. Divide the operation process of the reagent needle into multiple stages:

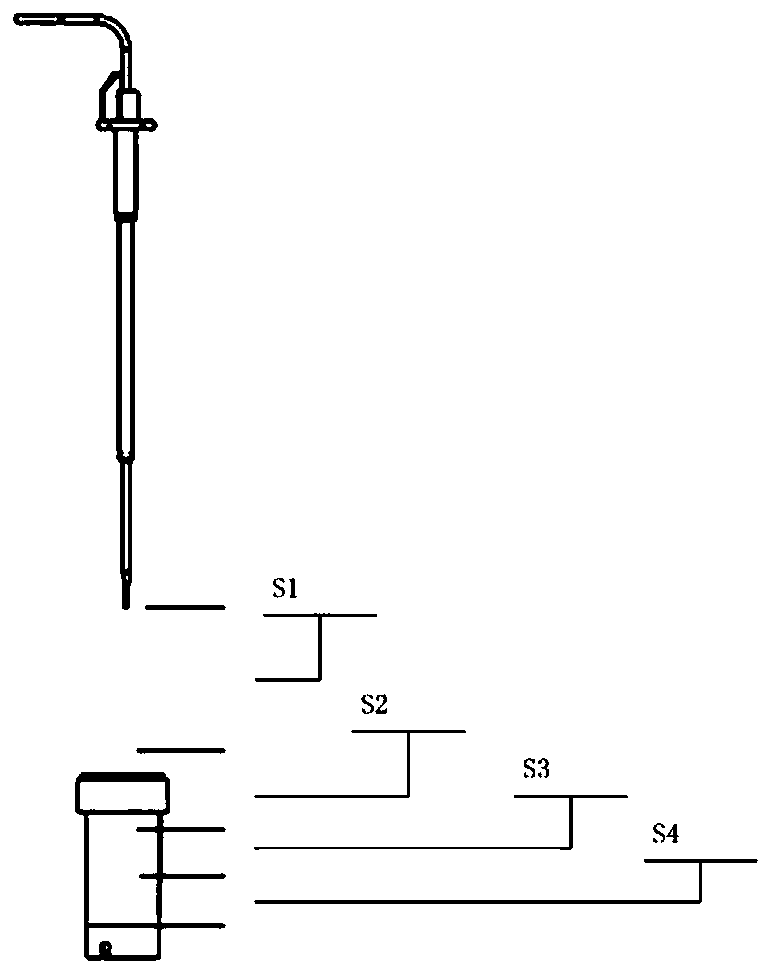

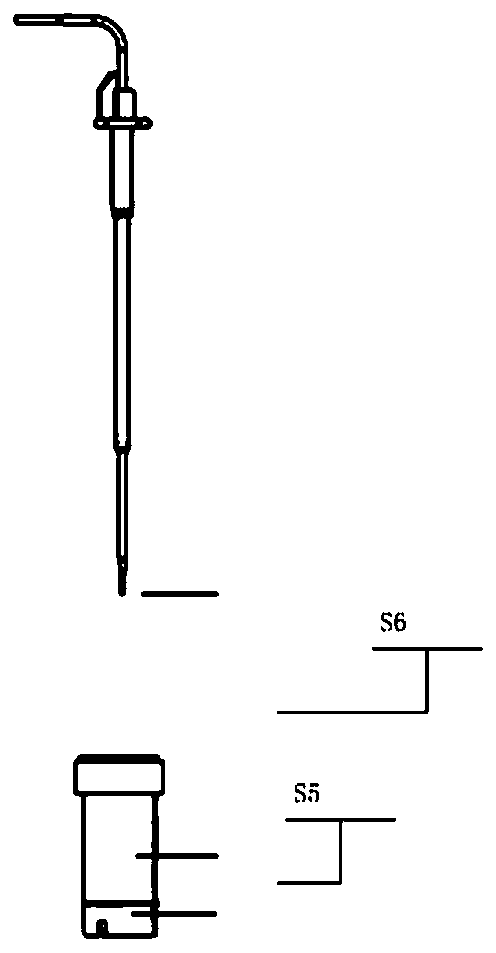

[0065] (1) Divide the process of the reagent needle moving downward from the initial position to the reagent liquid level to draw the reagent into 4 stages, specifically as follows: figure 1 shown, including:

[0066] The first stage S1: the reagent needle moves from the initial position to the set position above the reagent bottle mouth;

[0067] The second stage S2: the reagent needle moves from the set position above the reagent bottle mouth to the set position below the reagent bottle mouth in the reagent bottle;

[0068] The third stage S3: the reagent needle travels from the set position below the mouth of the reagent bottle in the reagent bottle to the first set position above the liquid level in the reagent bottle;

[0069] The fourth stag...

Embodiment 2

[0113] This embodiment provides a reagent needle operation control system for medical instruments, including:

[0114] The operation phase division module is used to divide the liquid extraction process of the reagent needle into multiple operation phases, and set the distance information of each operation phase. For the division of operation phases, refer to Embodiment 1.

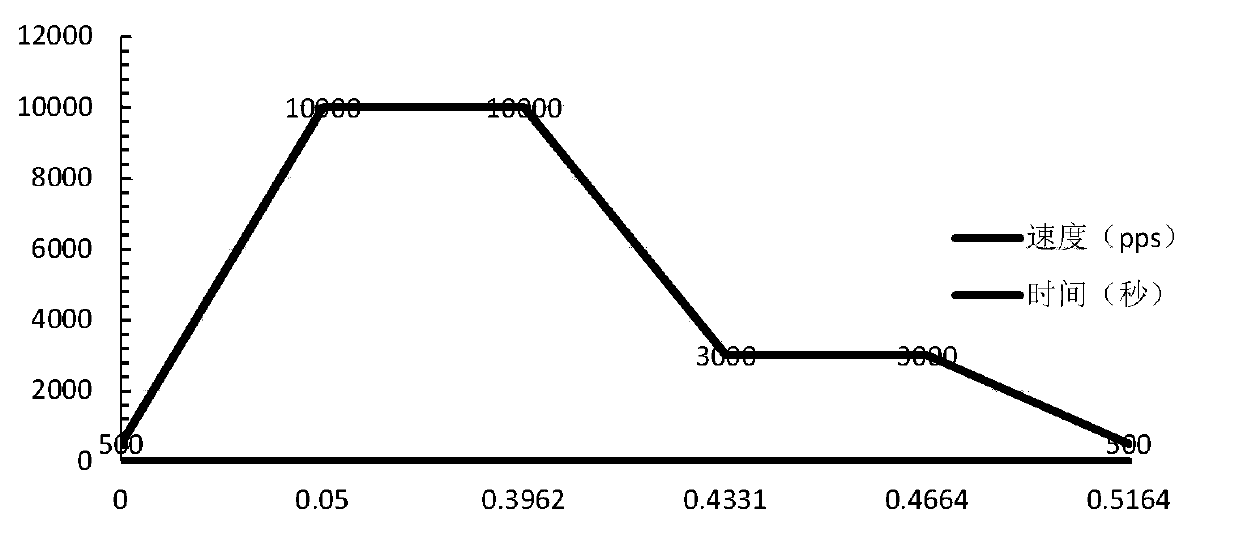

[0115] The parameter setting module is used to set operation control parameters, including the operation mode, operation time and operation speed of each operation stage. For the setting of operation control parameters, refer to Embodiment 1.

[0116] The operation control module is used to control the reagent needle to complete the operation of each stage according to the set operation control parameters, including: according to the set operation control parameters, control the reagent needle to run from the initial speed according to the set operation control parameters to the nth Operation stage, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com