Brand-new VCM motor coil straight winding base structure

A coil and motor technology, applied in the field of the new VCM motor coil directly wound base structure, can solve the problems of cumbersome assembly efficiency of VCM motors, high cost of finished product processing, high labor costs, etc., to achieve automatic operation, high production efficiency, and low processing difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

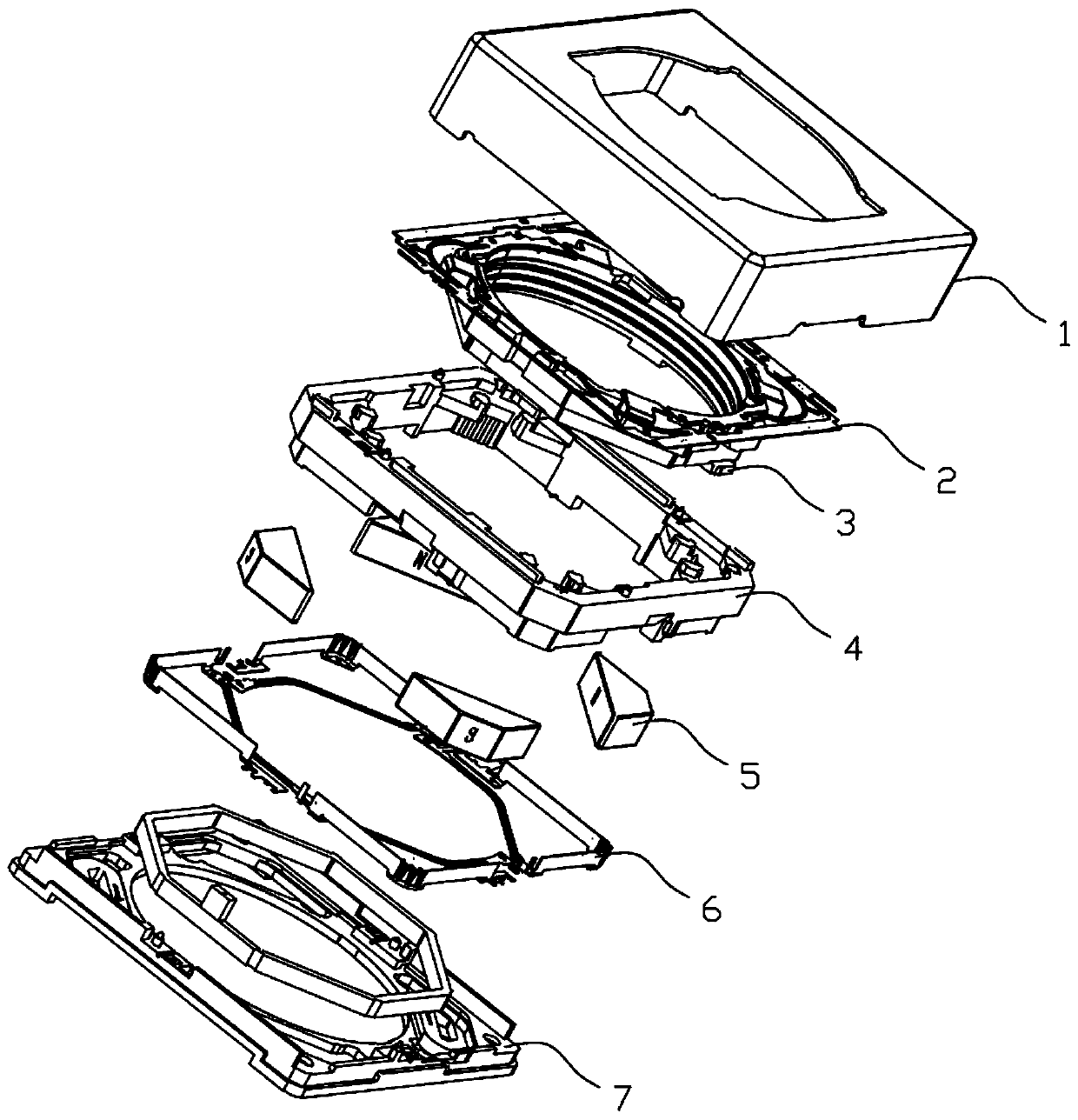

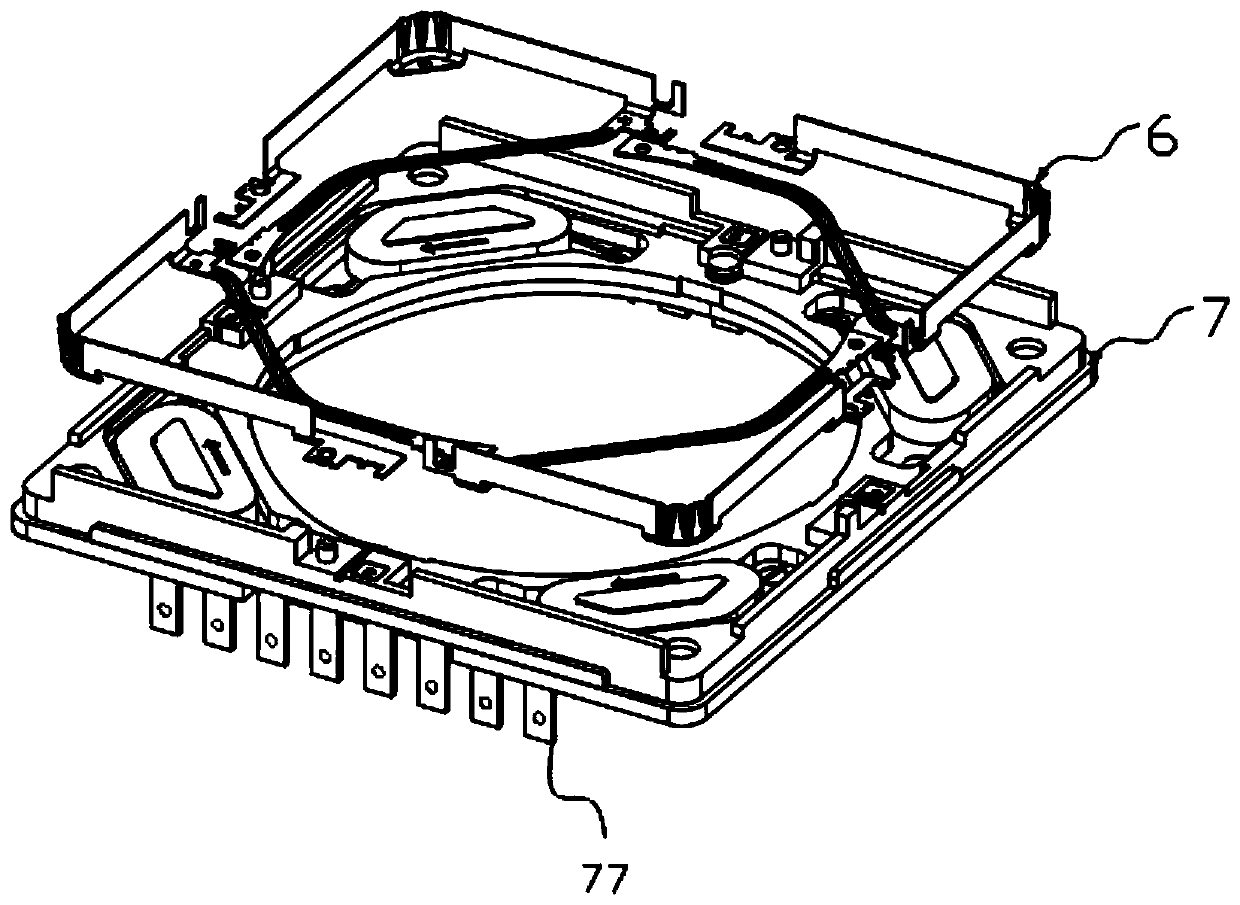

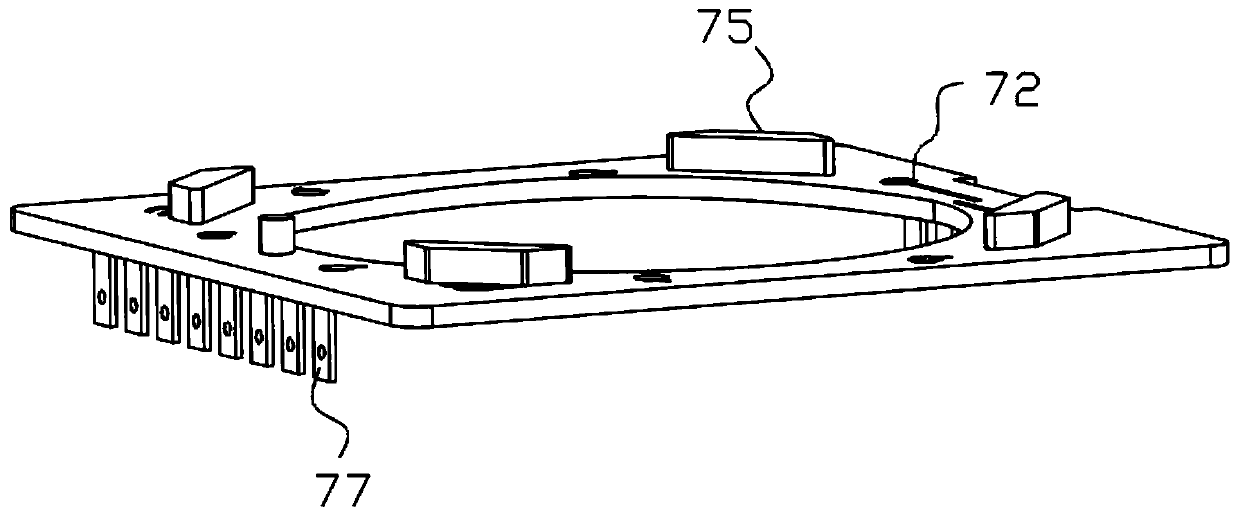

[0041] A brand-new VCM motor coil straight-wound base structure, including a base 7 formed by injection molding, and four straight-wound columns 75 corresponding to the four permanent magnets 5 in the VCM motor are arranged on the base 7 near the four corners. The coils 71 connected to each other are respectively arranged on the straight winding columns 75, and the copper wires connected between two adjacent coils 71 are in contact with the contacts 72 preset on the base 7 and located on both sides of the coils 71 respectively. The copper wires between the coils 71 are fixed by the fixed ribs 74 fixedly arranged on the base 7 .

[0042] The working principle of this embodiment is not substantially different from the working principle of the existing VCM motor, only the installation method of the base and the coil is changed, so that the technical effect can be changed through the change of the structure. In this embodiment, the coil 71 is positioned and installed by using the ...

Embodiment 2

[0046] On the basis of Example 1, further in conjunction with the attached Figure 4 In the structure shown, the fixed ribs 74 are arranged in parallel and in pairs, and are located in the middle of two adjacent coils 71 . The above-mentioned structure is used to respectively fix two adjacent coils, and at the same time, it is beneficial to the subsequent coil division. The two free ends of the divided copper wires are fixed by the fixing ribs 74 without any influence on the coils. , and is not affected by external force. There is no fixed sequence between the segmentation process and the welding process, which is more convenient to operate. The contact 72 always corresponds to the position of the copper wire, which greatly reduces the difficulty of welding, improves the accuracy of welding and one-time sexual success rate.

Embodiment 3

[0048] On the basis of the structure of Embodiment 1 or 2, in order to solve the problem that there are two free copper wire ends fixed when the integrated coil 71 is installed, the integrated coil 71 after installation is relative to the base 7. The positions of the copper wires between the two adjacent coils 71 are determined, so that during subsequent welding, the positions of the copper wires and the contacts 72 are determined, reducing the difficulty of welding, such as Figure 5 As shown: a terminal 76 for fixing the free ends of the two copper wires of the coil 71 is arranged between any pair of fixed ribs 74 arranged in parallel. There is a gap in between. Since the four coils 71 are an integral structure connected to each other before installation, the two coils 71 at the head and tail respectively have a free copper wire end. In order to further facilitate installation and welding, a terminal post 76 is provided on the base 7 for winding Fix the two free copper wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com