High polymer material crusher convenient for feeding

A polymer material and shredder technology, which is used in mechanical material recycling, plastic recycling, recycling technology, etc., can solve the problem of easy adhesion to the inner wall of the feeding hopper, increased manual labor intensity, and worker's hand injury. and other problems to achieve the effect of improving convenience, improving effect and facilitating feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

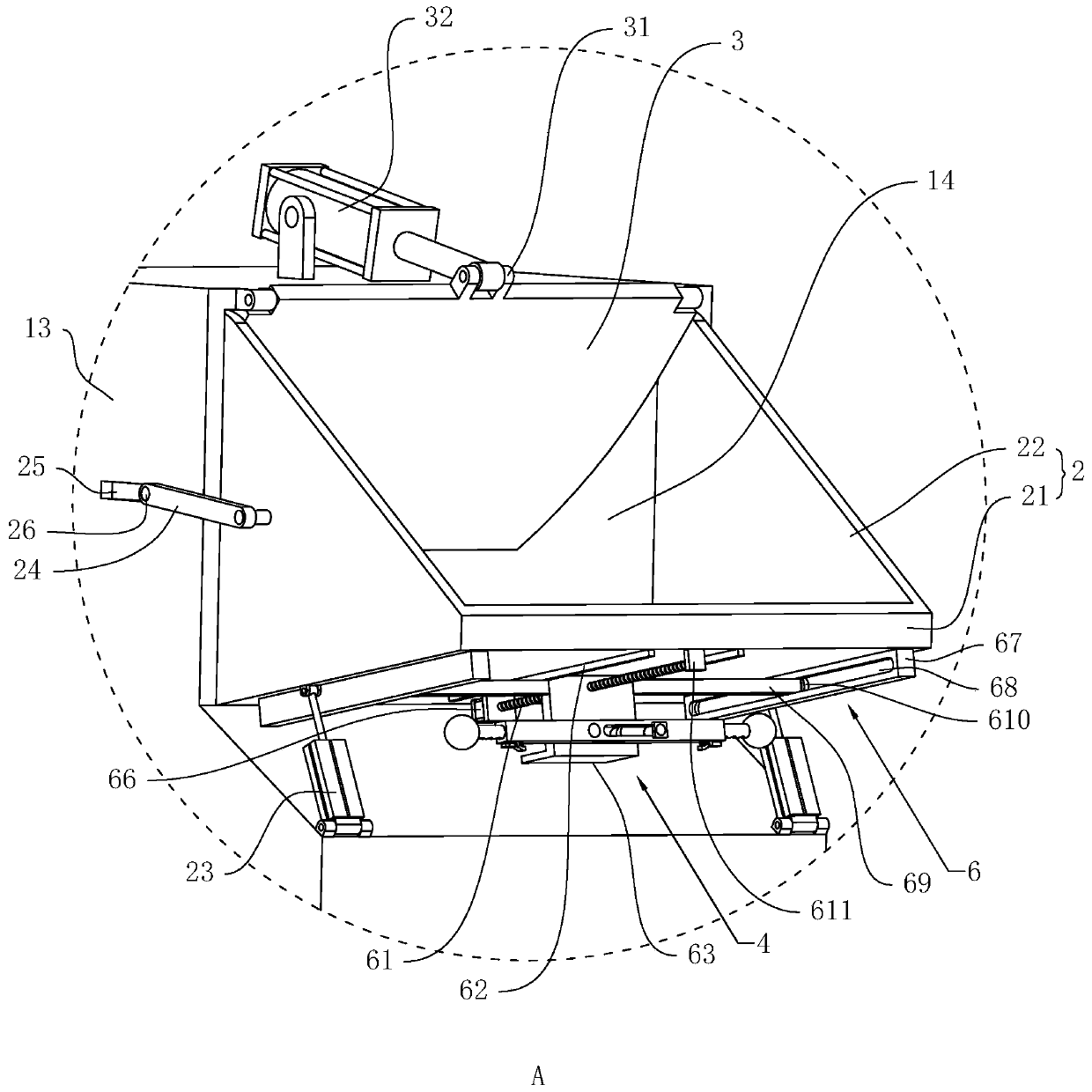

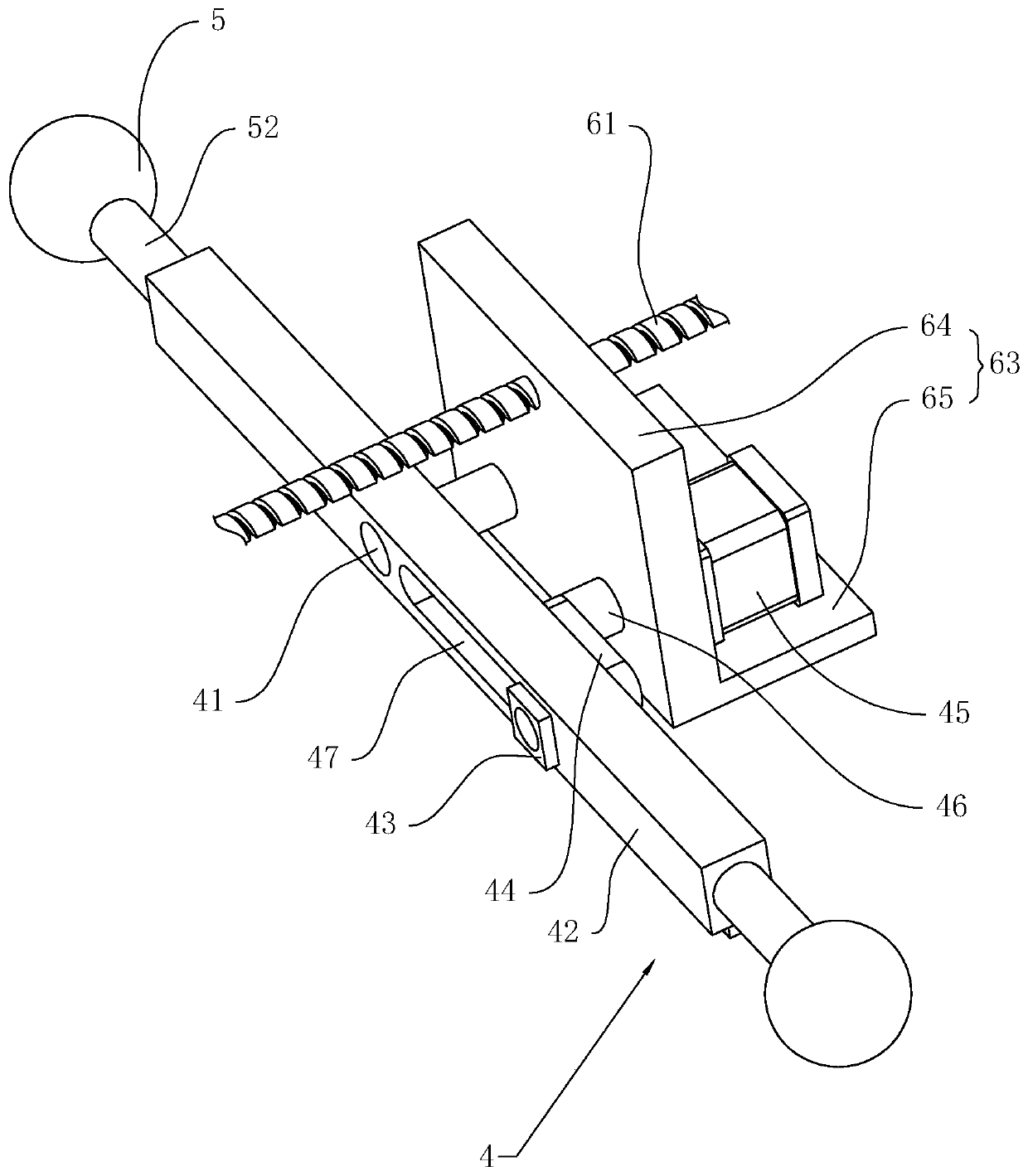

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

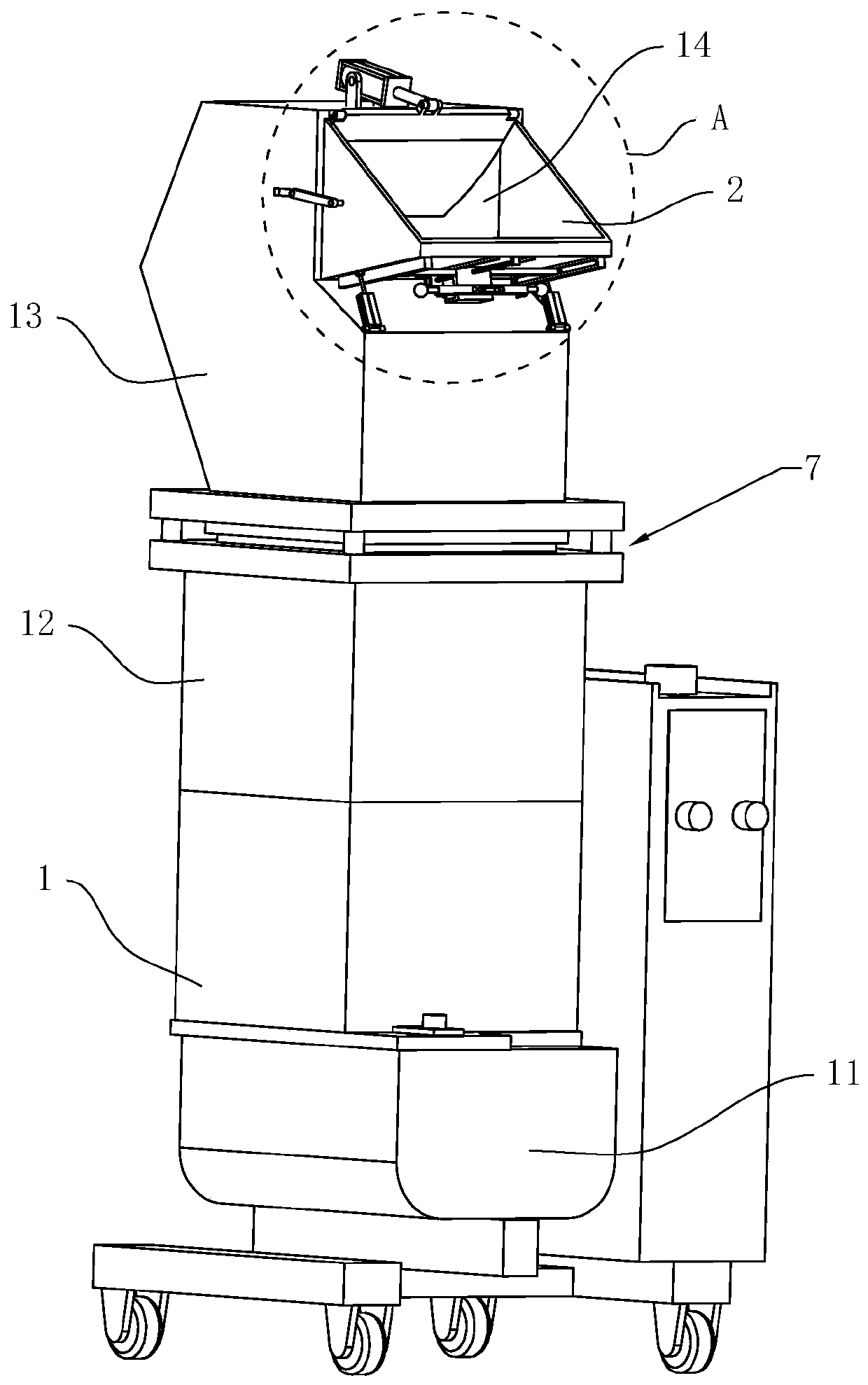

[0038] In this embodiment, if figure 1 As shown, it is a polymer material shredder disclosed by the present invention that is convenient for feeding, including a body 1, and a knife set (not shown in the figure) is installed inside the body 1, and the knife set can crush materials. The bottom of the body 1 Material receiving box 11 is installed, and material receiving box 11 can collect the fragment after crushing, and support seat 12 is fixed on the top of body 1, and support seat 12 is fixed with guide seat 13 away from the top side of body 1, and support seat 12 and guide The inside of the material seat 13 is provided with a feed channel (not shown in the figure) which communicates with each other. The material enters the interior of the body 1 through the feed channel, and the end of the material guide seat 13 away from the support seat 12 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com