A tool for machining internal threads of insulating pipe and using method thereof

A technology of internal thread and insulating pipe, which is applied in metal processing equipment, thread cutting auxiliary equipment, thread cutting device, etc., can solve the problems of thread peeling and tooth loss, prevent tooth loss, improve production efficiency, and solve the problem of large cutting force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 is used to process the tooling of insulating pipe internal thread

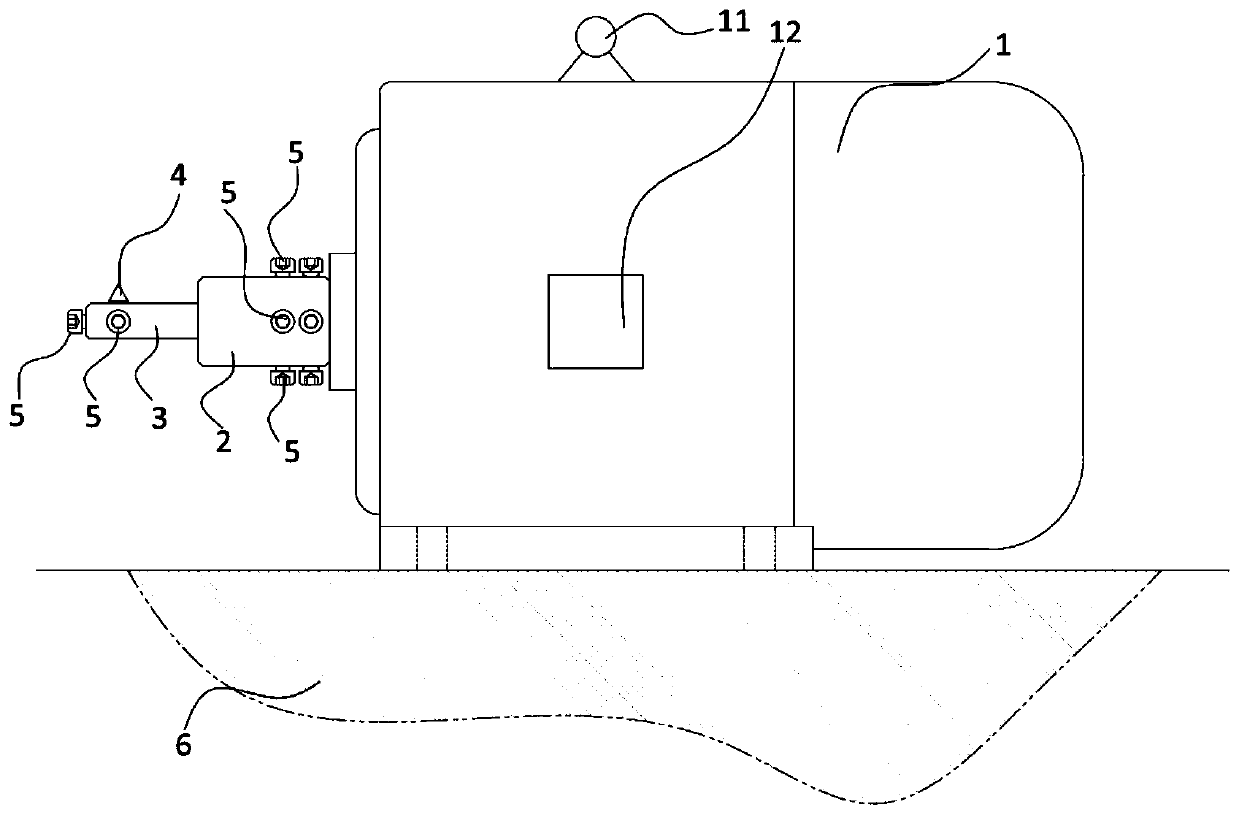

[0049] The frock for processing the internal thread of an insulating pipe described in this embodiment includes a high-speed motor 1, a guide seat 2, a cutter bar 3 and a turning tool 4, and the high-speed motor 1 is arranged on a large pallet 6 of a lathe, and the high-speed motor 1 The central axis of the center axis is connected with the guide seat 2, and the guide seat 2 is connected with the tool bar 3, and the turning tool 4 is installed on the tool bar 3, and the guide seat 2 is kept horizontal with the lathe guide rail, and the turning tool 4 is connected with the guide seat 2 vertical.

Embodiment 2

[0050] Embodiment 2 Tooling for processing internal threads of insulating pipes

[0051] The frock for processing the inner thread of the insulating pipe described in this embodiment, see Figure 1-Figure 11 , including a high-speed motor 1, a guide seat 2, a tool bar 3 and a turning tool 4, the high-speed motor 1 is arranged on a large pallet 6 of a lathe, and the central axis of the high-speed motor 1 is connected with the guide seat 2 through a locking screw 5 , the guide seat 2 and the tool bar 3 are threadedly connected, the turning tool 4 is installed on the tool bar 3, the tool bar 3 and the turning tool 4 are fixed by locking screws 5, and the guide seat 2 is maintained with the lathe guide rail Horizontal, the turning tool 4 is perpendicular to the guide seat 2.

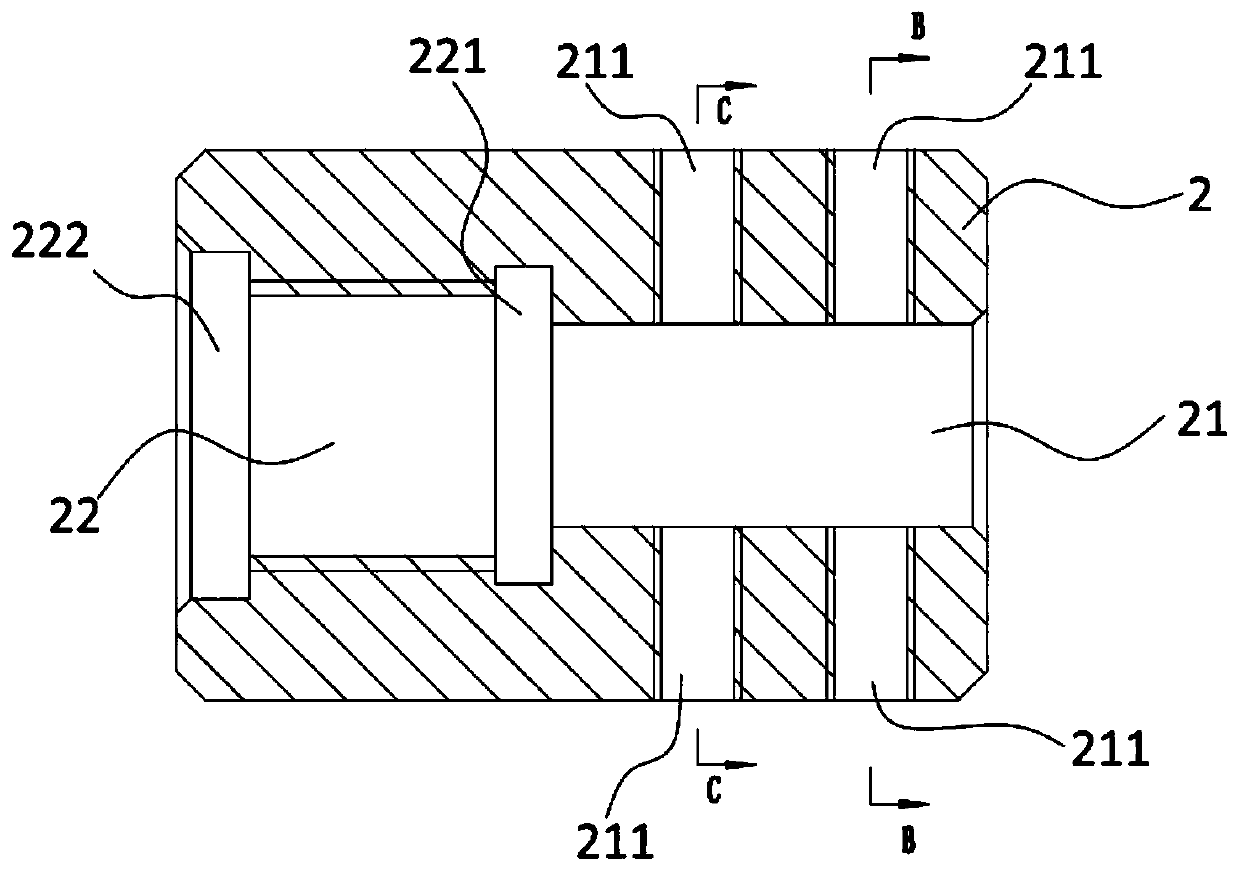

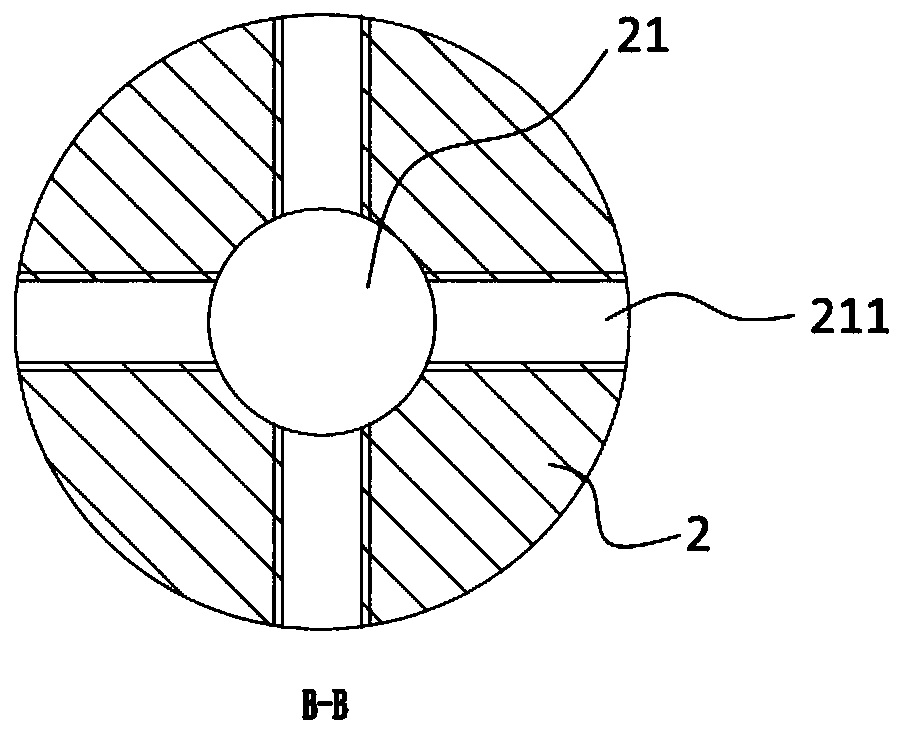

[0052]In the above-mentioned tooling for processing the internal thread of the insulating pipe, the center of one end of the guide seat 2 is provided with a first mounting hole 21 for installing the central...

Embodiment 3 Embodiment 2

[0053] Embodiment 3 The use method of the tooling for processing the internal thread of the insulating pipe described in the embodiment 2

[0054] The method for using the tooling for processing the internal thread of the insulating pipe described in this embodiment includes the following steps:

[0055] Step 1, install high-speed motor 1 and adjust the center height;

[0056] Step 2, install the guide seat 2 and adjust it to be level with the guide rail of the lathe;

[0057] Step 3, install the tool bar 3 and the turning tool 4 and adjust the turning tool 4 to be perpendicular to the guide seat 2;

[0058] Step 4, select the corresponding tool according to the pitch;

[0059] Step five, start the high-speed motor 1 to drive the turning tool 4 to rotate at high speed;

[0060] Step 6, the turning tool 4 is fed, and the feed amount is 0.8*pitch;

[0061] Step 7, process to the thread depth and exit, and the internal thread processing of the insulating pipe is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com