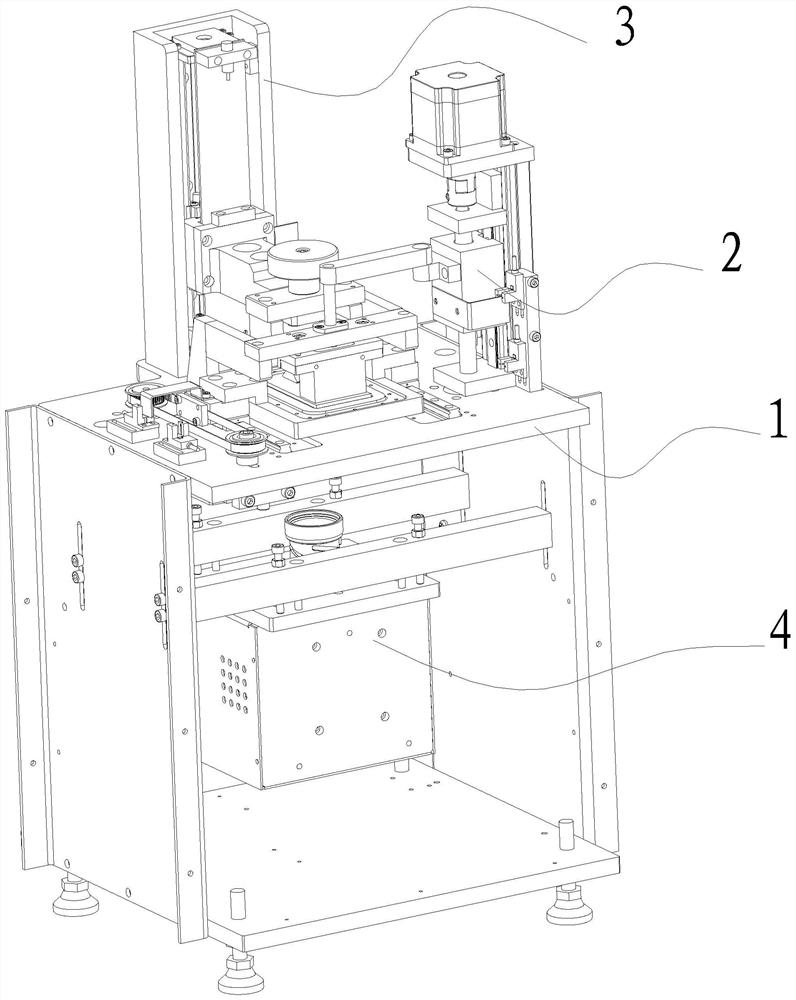

A 3D printing quantitative feeding device, 3D printer and printing method

A 3D printing and feeding device technology, applied to 3D object support structures, ceramic molding machines, manufacturing tools, etc., can solve problems such as poor printing accuracy, achieve the effect of saving materials and improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

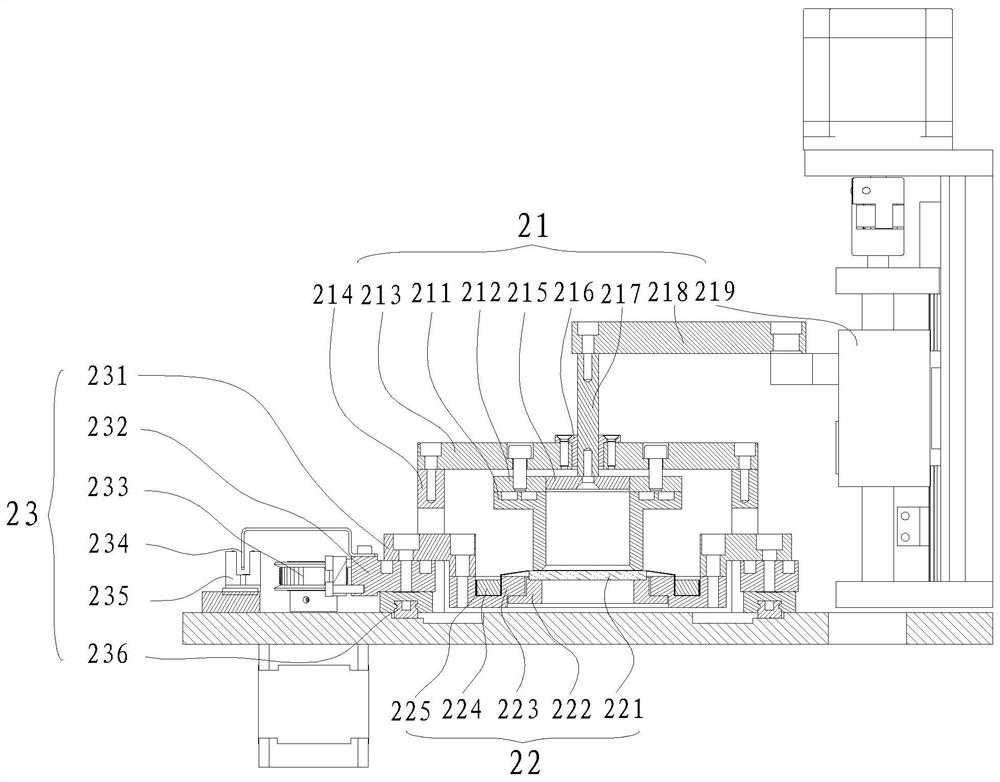

[0031] The feeding assembly includes a material box 211, a guide shaft 217, a pressing rod 218 and an extruding plate 215. The upper part of the guiding shaft 217 is connected to the pressing bar 218, and the lower part of the guiding shaft 217 is connected to the extruding plate 215. The extruding plate 215 cooperates with the inner diameter of the material box 211 , and the bottom of the material box 211 is arranged on a plane.

[0032] Specifically, the material box 211 is used to contain printing materials. The bottom of the material box 211 is parallel to the glass of the material loading platform 22, and the distance is 0.1-0.3 mm. The bottom of the material box 211 requires flatness during processing, which can be Use as a scraper. The material loading platform 22 drives the material to move. After passing through the material box 211, the material is scraped flat by the bottom of the material box and evenly spread on the material loading platform, creating conditions f...

Embodiment 2

[0034] A fixing plate 212 is also included, the fixing plate 212 is located above the material box 211 , and the fixing plate 212 and the material box 211 are positioned through magnetic attraction and / or pin holes.

[0035] Specifically, the fixing plate 212 is used to fix the material box 211. The side of the material box 211 is provided with pin holes, and four circular holes are provided on the top for installing a circular magnetic block. The fixed plate 212 Pin holes are provided on the side, and pins are installed. The material of the fixing plate 212 is iron, and the material box 211 is positioned with the fixing plate by the pins, and is fixed on the fixing plate by the suction force of the magnetic attraction. This facilitates the disassembly and replacement of the material box.

Embodiment 3

[0037] The loading platform 22 includes a loading glass plate 221, a transparent film 225, a glass clamping plate 222, a film clamping plate 223 and a pressing plate 224. The glass clamping plate 222 is provided with a slot, and the loading glass plate 221 is installed In the slot of the glass clamp 222, the transparent film 225 is covered on the film clamp 223, and the surrounding of the transparent film 225 is pressed tightly in the slot of the film clamp 223 by the pressure plate 224, The glass clamp 222 is connected to the film clamp 223 .

[0038] Specifically, the loading platform 22 is used to carry materials, and the loading glass plate 221 is made of a transparent material, which can transmit light from the bottom. The glass clamping plate 222 is empty in the middle and has steps around it. The middle of the clamping plate 223 is empty, and there are grooves all around. The grooves around the film clamping plate 223 match the dimensions of the pressing plate 224, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com