Refrigerant replacing R410, and preparation method and application for refrigerant

A refrigerant and refrigeration system technology, applied in the direction of chemical instruments and methods, heat exchange materials, sustainable manufacturing/processing, etc., can solve the problems of replacing new air conditioners, and achieve the effect of increasing latent heat, good stability, and large latent heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

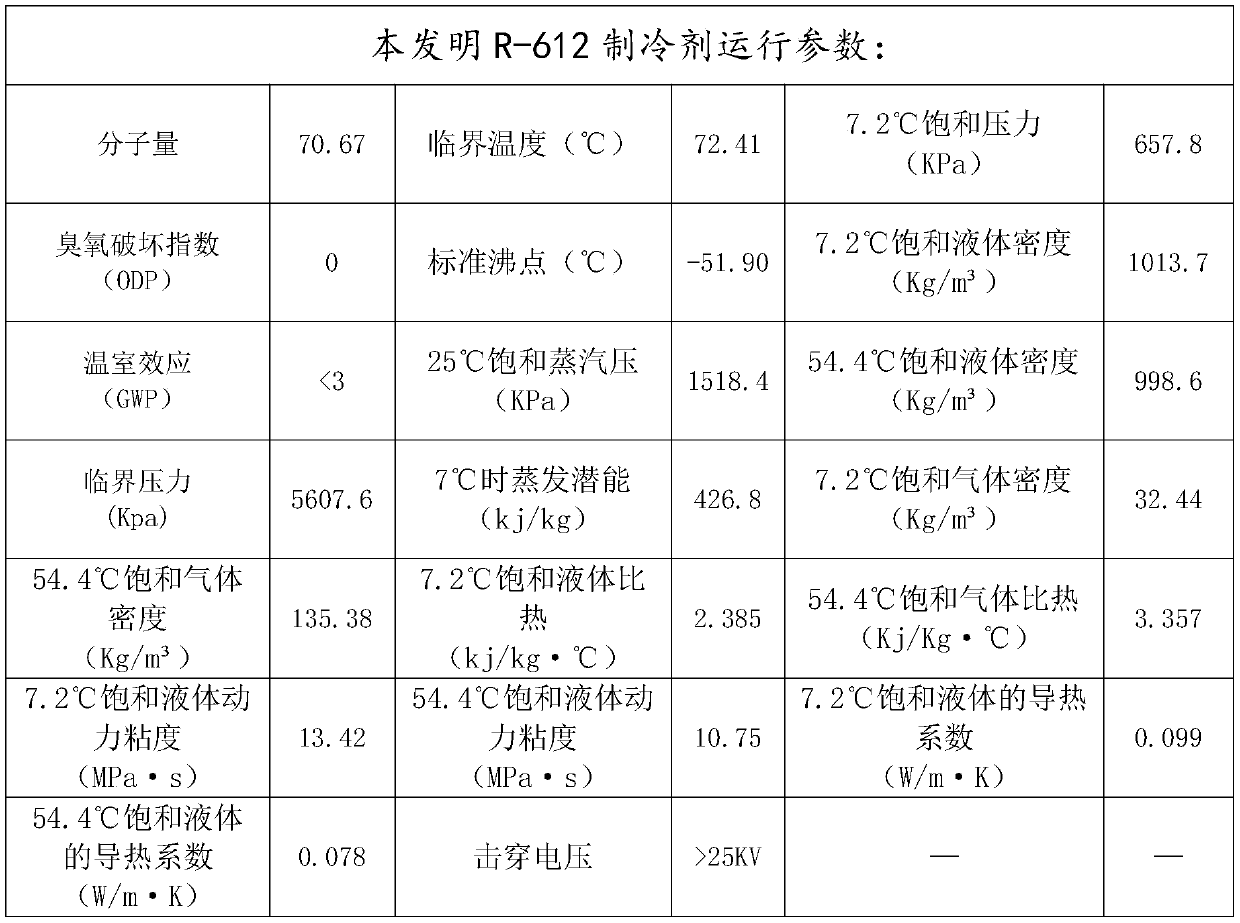

Image

Examples

Embodiment 1

[0030] A refrigerant substituting R-410, which is made by fully mixing the following raw materials in percentage by weight: 26% of fluoroethane, 50% of difluoroethane, and 24% of trifluoroiodomethane. Its preparation method is as follows:

[0031] S1. Carry out rectification and purification of the three raw materials on the production line, and the rectification tower meets the height and standard of 99.96% of the refrigerant raw materials;

[0032] S2. The purity of the three raw materials is tested by an Agilent color analyzer to ensure that the purity reaches 99.96% of refrigerant grade;

[0033] S3. Connect the fully automatic and multi-functional microwave vacuum mixing tank, the model of the fully automatic and multi-functional microwave vacuum mixing tank is; YDL--6000L;

[0034] S4. Vacuumize the fully automatic mixing tank to reach a negative pressure state;

[0035] S5. Add the qualified raw materials into the automatic mixing tank according to the ratio of parts ...

Embodiment 2

[0040] A refrigerant substituting R-410, which is made by fully mixing the following raw materials in percentage by weight: 20% of fluoroethane, 55% of difluoroethane, and 25% of trifluoroiodomethane. Its preparation method is the same as that of Example 1.

Embodiment 3

[0042] A refrigerant substituting R-410, which is made by fully mixing the following raw materials in percentage by weight: 28% of fluoroethane, 48% of difluoroethane, and 24% of trifluoroiodomethane.

[0043] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com