Suspension acid thickening agent and preparation method thereof

A technology of thickening agent and suspending acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low viscosity, easy agglomeration, poor dispersibility of thickened acid, etc., and achieve high viscosity and not easy agglomeration , The effect of slurry stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

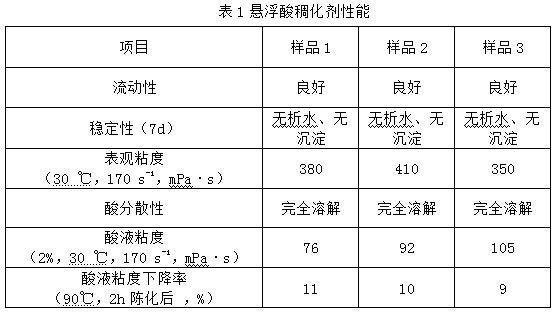

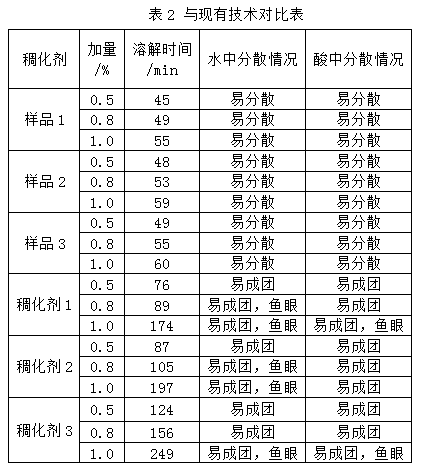

Examples

Embodiment 1

[0038] A kind of suspending acid thickener, comprises following composition by weight percentage:

[0039] No. 3 white oil: 12 wt%,

[0040] No. 26 white oil: 10 wt%,

[0041] No. 100 white oil: 8 wt%,

[0042] No. 200 white oil: 10 wt%,

[0043] Organic bentonite: 6 wt%,

[0044] 100 mesh bentonite: 3 wt%,

[0045] 140 mesh kaolin: 9 wt%,

[0046] 160 mesh diatomaceous earth: 12 wt%,

[0047] 200 mesh fly ash: 9 wt%,

[0048] 95% ethanol: 3 wt%,

[0049] Thickener: 18 wt%.

[0050] Stir and mix the above-mentioned raw materials evenly in proportion, and the stirring time is 2 hours. After the stirring is completed, it is the product, code-named sample 1.

Embodiment 2

[0052] A kind of suspending acid thickener, comprises following composition by weight percentage:

[0053] No. 3 white oil: 19 wt%,

[0054] No. 26 white oil: 5 wt%,

[0055] No. 100 white oil: 6 wt%,

[0056] No. 200 white oil: 9 wt%,

[0057] Organic bentonite: 5 wt%,

[0058] 100 mesh bentonite: 7 wt%,

[0059] 140 mesh kaolin: 7 wt%,

[0060] 160 mesh diatomaceous earth: 7 wt%,

[0061] 200 mesh fly ash: 11 wt%,

[0062] 95% ethanol: 2 wt%,

[0063] Thickener: 22 wt%.

[0064] Stir and mix the above-mentioned raw materials evenly in proportion, and the stirring time is 2 hours. After the stirring is completed, it is the product, code-named sample 2.

Embodiment 3

[0066] A kind of suspending acid thickener, comprises following composition by weight percentage:

[0067] No. 3 white oil: 15 wt%,

[0068] No. 26 white oil: 13 wt%,

[0069] No. 100 white oil: 5 wt%,

[0070] No. 200 white oil: 8 wt%,

[0071] Organic bentonite: 3 wt%,

[0072] 100 mesh bentonite: 5 wt%,

[0073] 140 mesh kaolin: 6 wt%,

[0074] 160 mesh diatomaceous earth: 9 wt%,

[0075] 200 mesh fly ash: 12 wt%,

[0076] 95% ethanol: 1 wt%,

[0077] Thickener: 23 wt%.

[0078] Stir and mix the above-mentioned raw materials evenly in proportion, and the stirring time is 2 hours. After the stirring is completed, it is the product, code-named sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com