Foundation reinforcement pressure bearing and drawing resisting composite anchorage structure and anchorage method thereof

A technology of foundation reinforcement and anchoring structure, applied in foundation structure engineering, soil protection, sheet pile wall and other directions, can solve the problems of construction difficulty, high noise, time-consuming and laborious, hidden safety hazards of the original foundation, etc., to improve the speed of construction and Efficiency, simplicity of manufacture and installation, quick and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

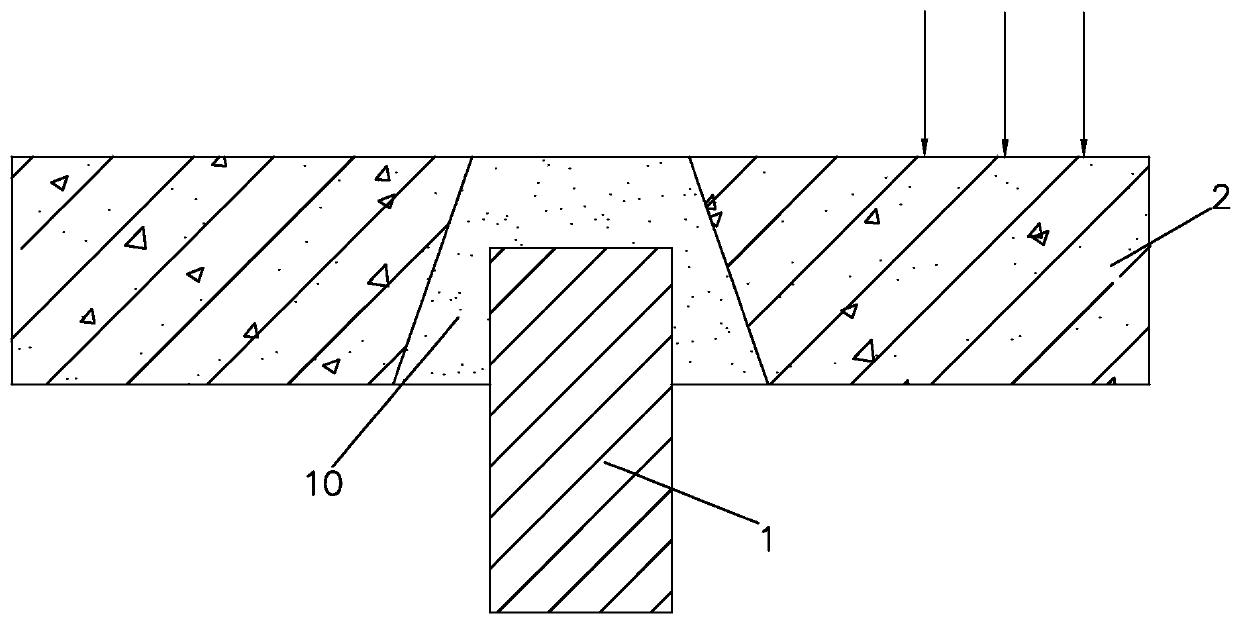

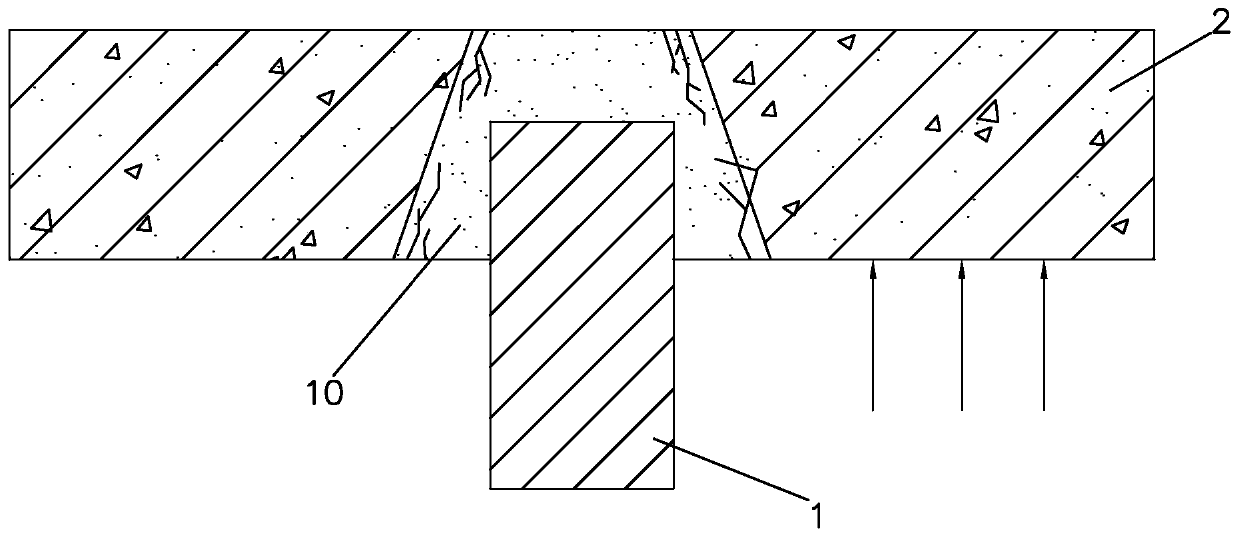

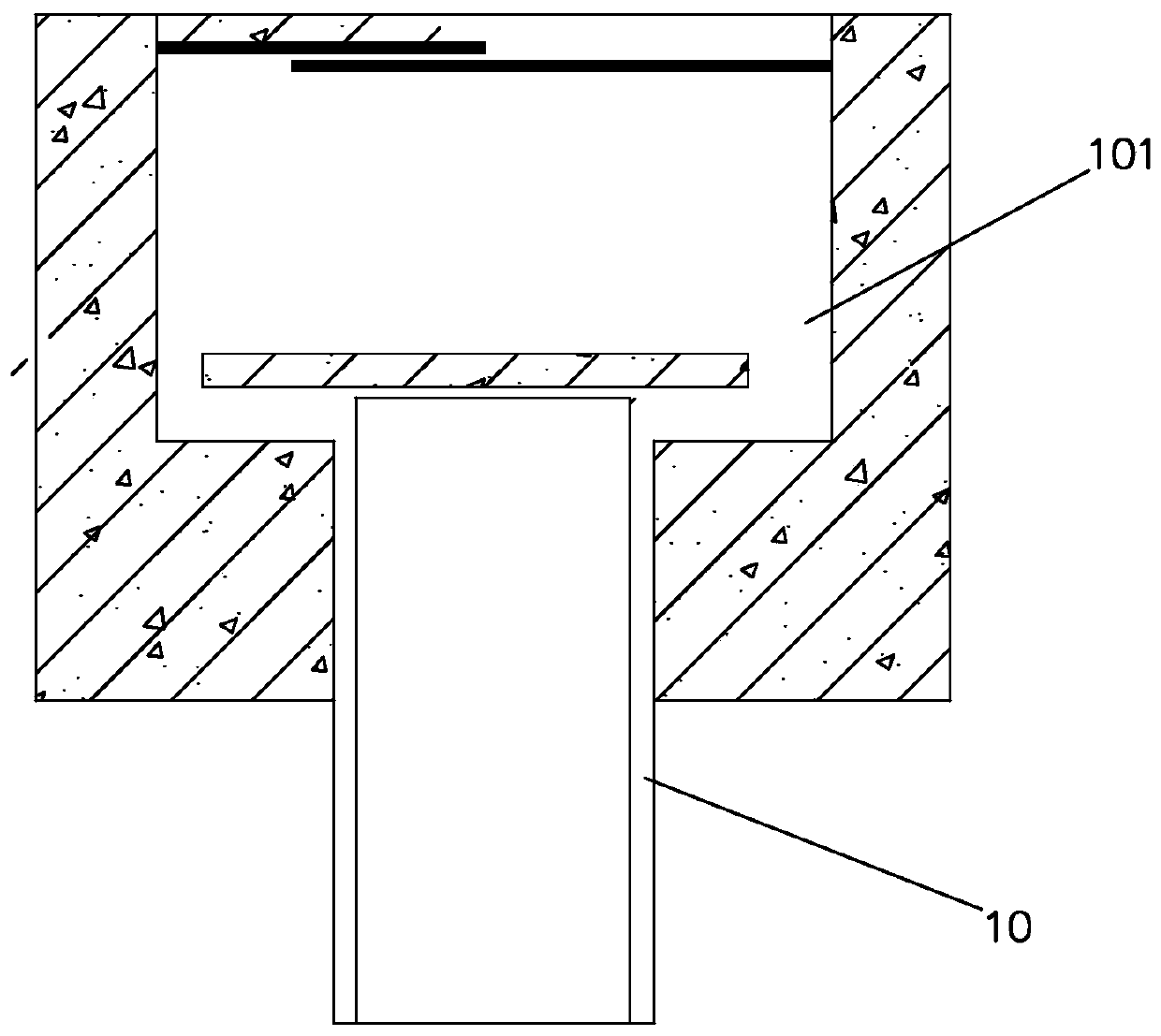

[0033] refer to Figure 4 and Figure 5 , the present embodiment relates to foundation reinforcement compression and pullout composite anchoring structure, including pile top member 1, anchor rod 2, pullout anchor rod 3 and anchor head 4, the pile top member 1 is arranged on the original foundation 10 and the new On the upper surface of the added pile 11, several through holes are opened on the pile top member 1, and the lower ends of the anchor rod 2 and the pullout anchor rod 3 are respectively anchored with the original foundation 10 and the newly added pile 11, and the anchor rod 2 and the The upper end of the uplift anchor rod 3 passes through and extends out of the through hole; the anchor head 4 is arranged on the upper surface of the pile top member 1 , and the anchor head 4 is anchored with the upper ends of the anchor rod 2 and the uplift anchor rod 3 .

[0034] When the newly added pile 11 is subjected to the vertical load from the superstructure, the pile foundati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com