Double-wall steel hanging box cofferdam provided with rapid mounting and dismounting double lock catch devices

A locking device, steel hanging box technology, applied in construction, infrastructure engineering and other directions, can solve the problems of low construction efficiency, high safety risk, long time for dismantling, etc., to achieve convenient construction control, strong operability, and accurate saving The effect of the adjustment and welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

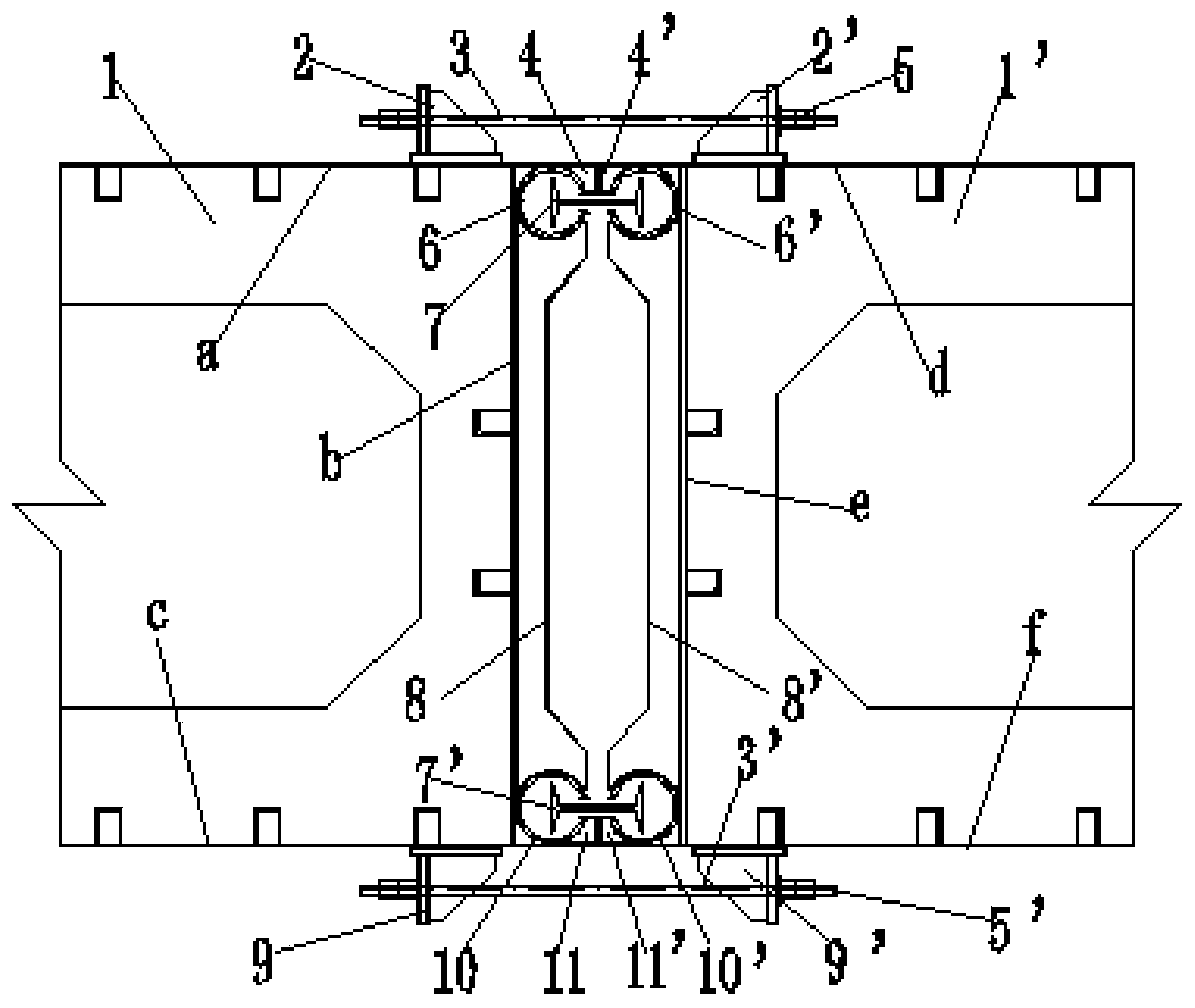

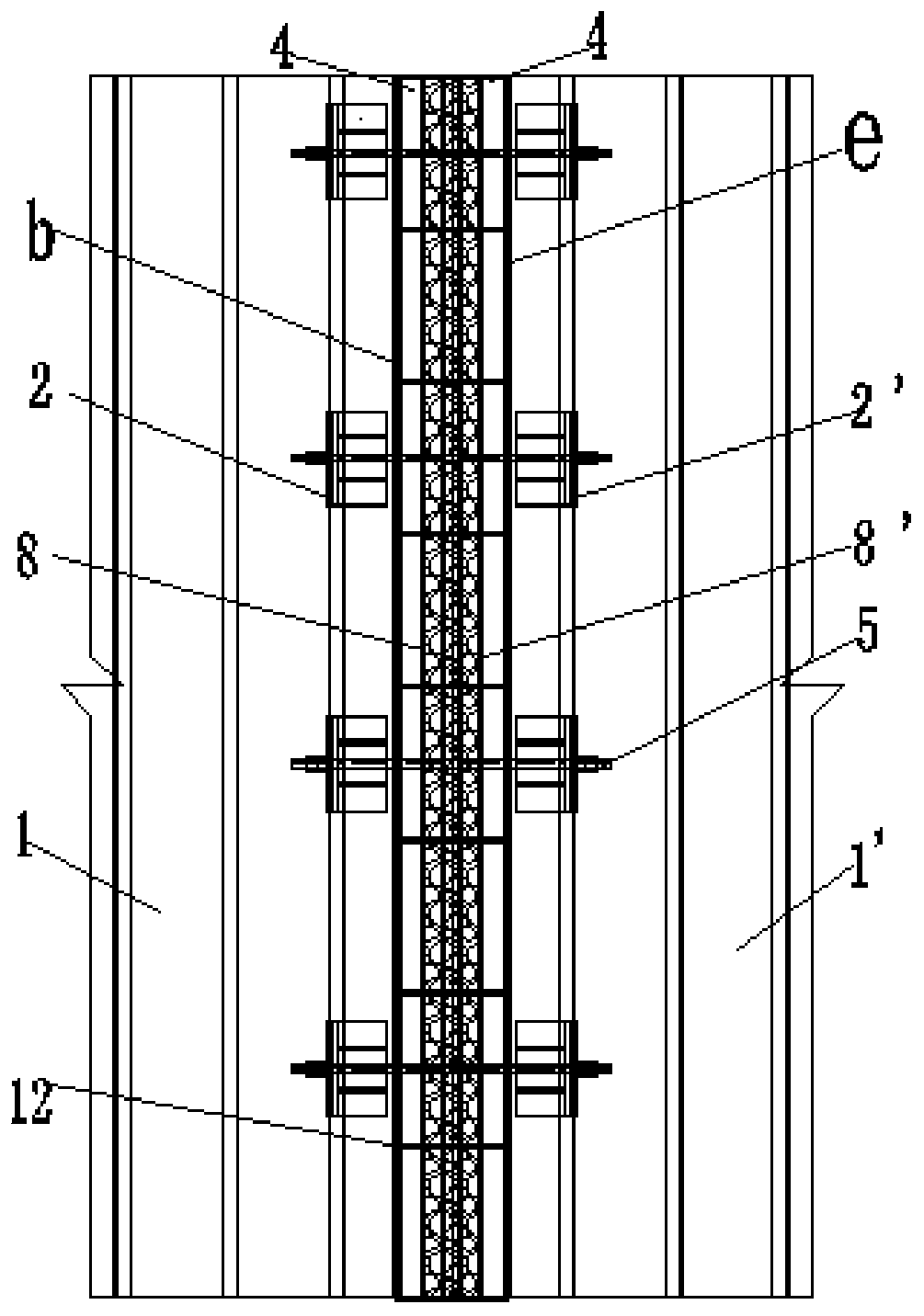

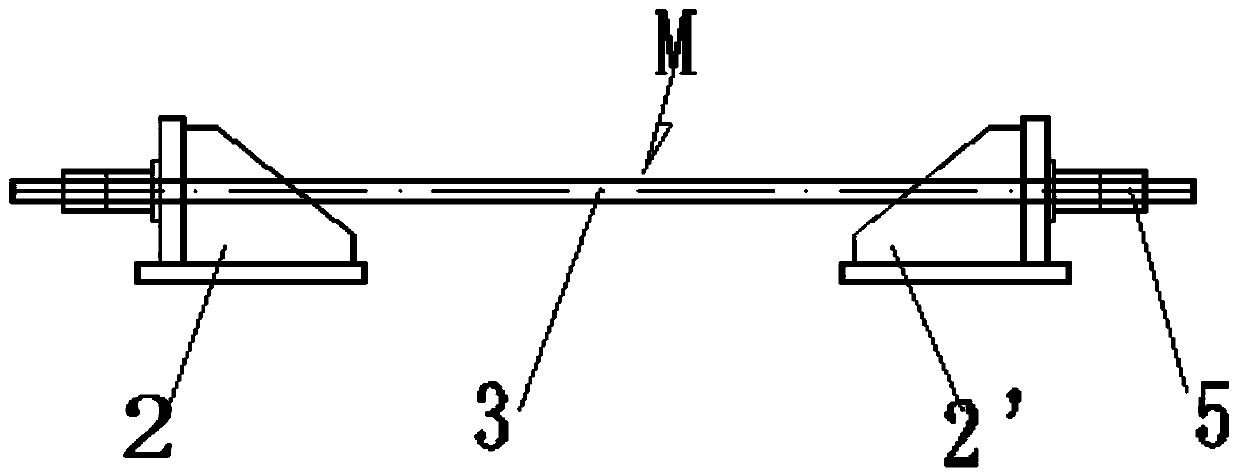

[0031] given in the present invention figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the embodiment, a double-walled steel hanging box cofferdam equipped with quick assembly and disassembly double locking devices, the first C-shaped pipe 6 and the second C-shaped pipe 6' are longitudinally welded to the first steel hanging box respectively 1's second box wall plate b and the fifth box wall plate e front end outer box wall of the second steel hanging box 1'; the third C-shaped pipe 10 and the fourth C-shaped pipe 10' are longitudinally welded on the first The second box wall plate b of the steel hanging box 1 and the fifth box wall panel e of the second steel hanging box 1' are on the outer box wall at the rear end.

[0032] In this embodiment, the wing plates at both ends of the first I-shaped steel 7 are installed in the first C-shaped tube 6 and the second C-shaped tube 10 respectively, and the two end wing plates of the second I-shaped steel 7' are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com