Multistage compression type heating radiator bottom drainage automatic regulating tool

An automatic adjustment and compression technology, applied in heating methods, home appliances, central heating components, etc., can solve problems such as low efficiency and inconvenient operation, and achieve the effects of convenient use, simple structure and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

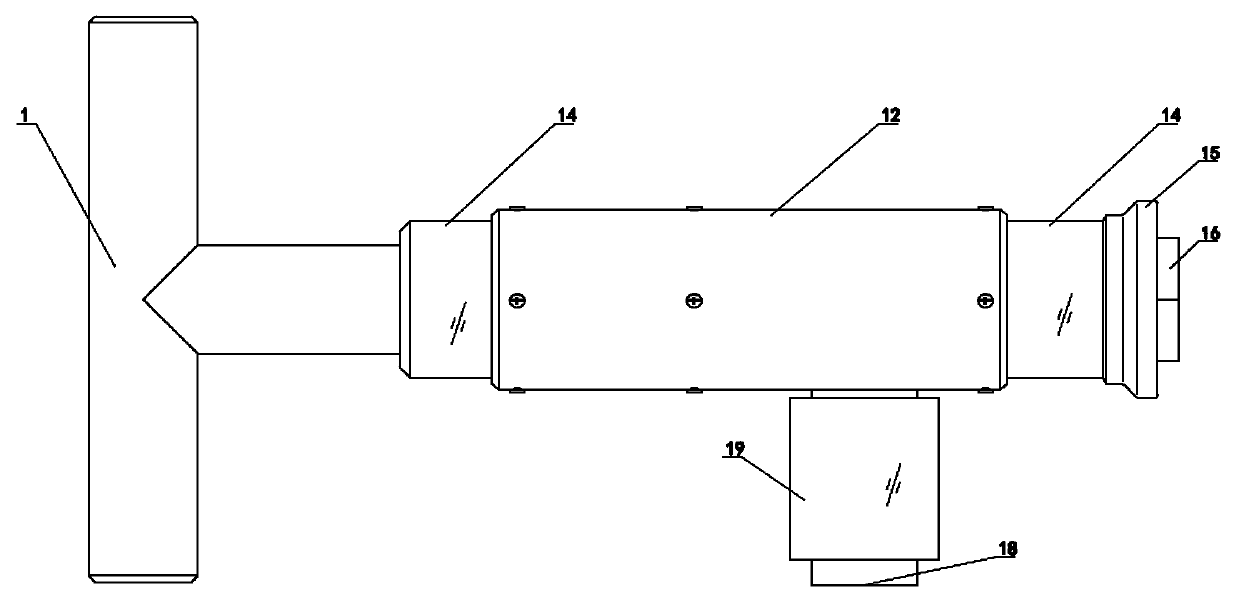

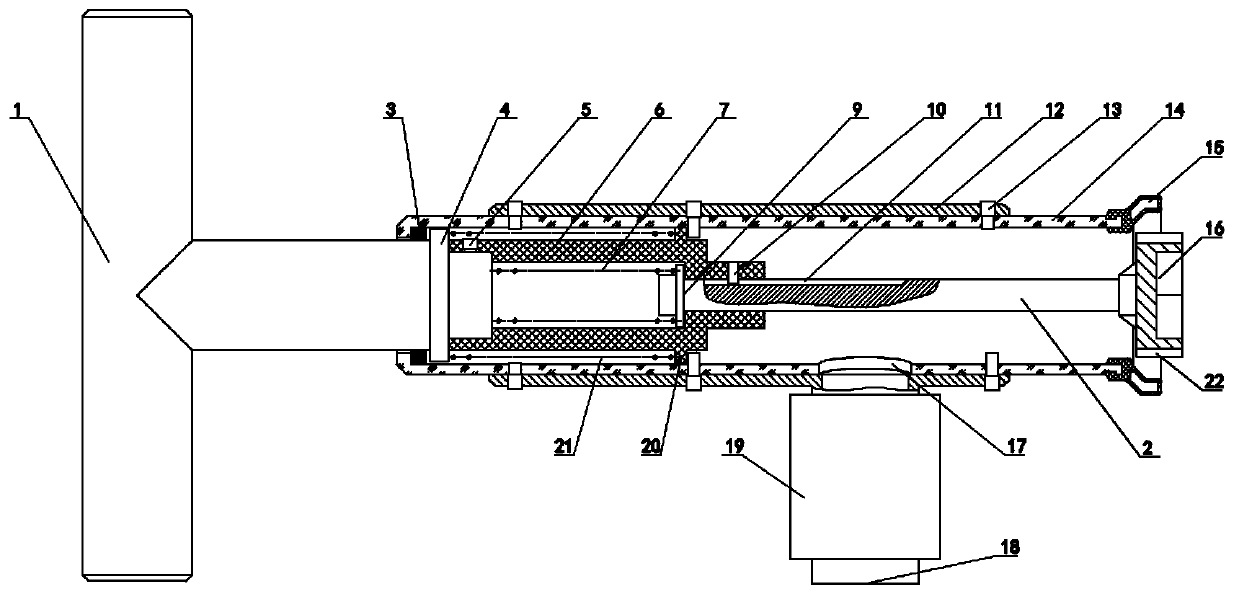

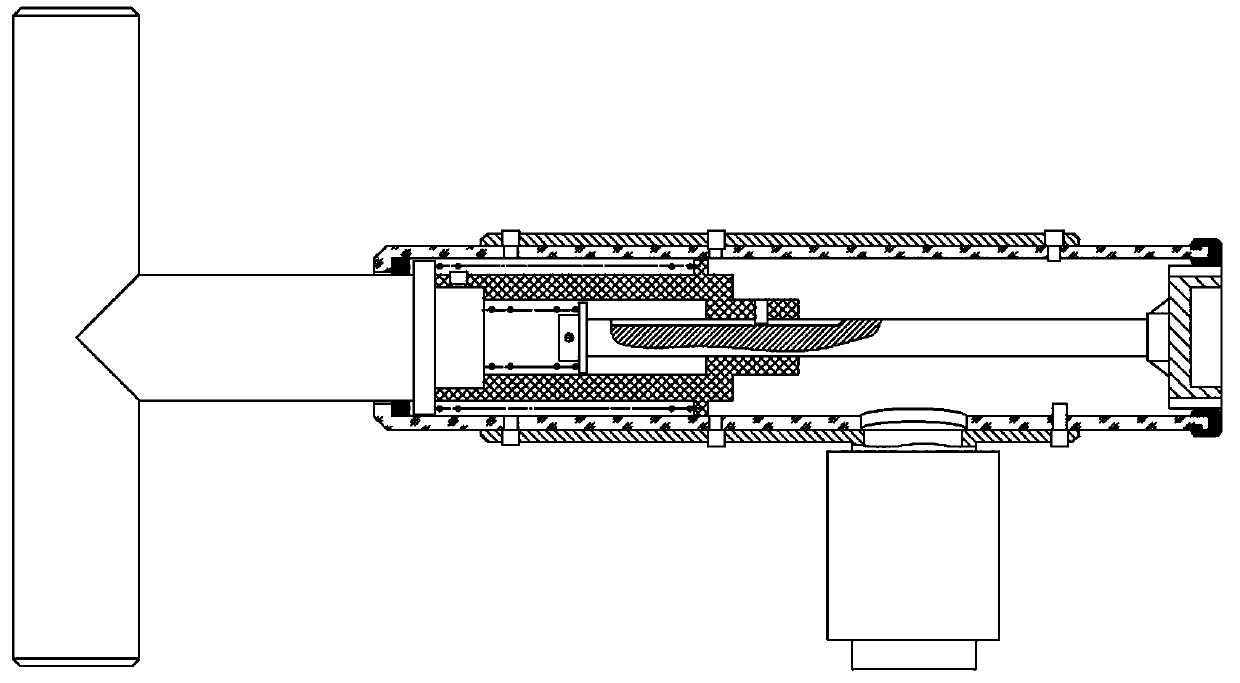

[0017] Embodiment 1: a kind of as figure 1 The shown automatic adjustment tool applied to the drain bolt at the bottom of the radiator can realize sealed butt joint and rigid connection through multi-stage compression. This function can be realized only by pressing, and the operation is simple and convenient. In the original state, the inner hexagonal butt joint is in an exposed state, and it can be docked with the cap of the standard hexagonal column drain bolt at the bottom of the radiator by operation. After one level of pressing, the inner hexagonal butt joint can move backwards The inside of the transparent cover is indented, such as image 3 As shown, the rubber sleeve located at the front end of the transparent cover can be sealed in the area around the drain bolt to form a block to prevent the drain from leaking out. Further, through two-stage pressing, the transparent cover can be slid to the side of the T-shaped handle, such as Figure 4 As shown, so that the inner...

Embodiment 2

[0024] Embodiment 2: On the basis of Embodiment 1, in this embodiment, the diameter of the hexagonal butt joint is matched with the inner wall of the transparent cover or the inner wall of the rubber sleeve, and the outer wall of the hexagonal butt joint is provided with radial side grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com