Marine VOC and BOG comprehensive liquefaction system and method

A marine re-liquefaction technology, applied in the comprehensive liquefaction system and its liquefaction field, can solve the problems of high power consumption and low energy efficiency, and achieve the effects of improving liquefaction recovery rate, reducing operating energy consumption, and system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

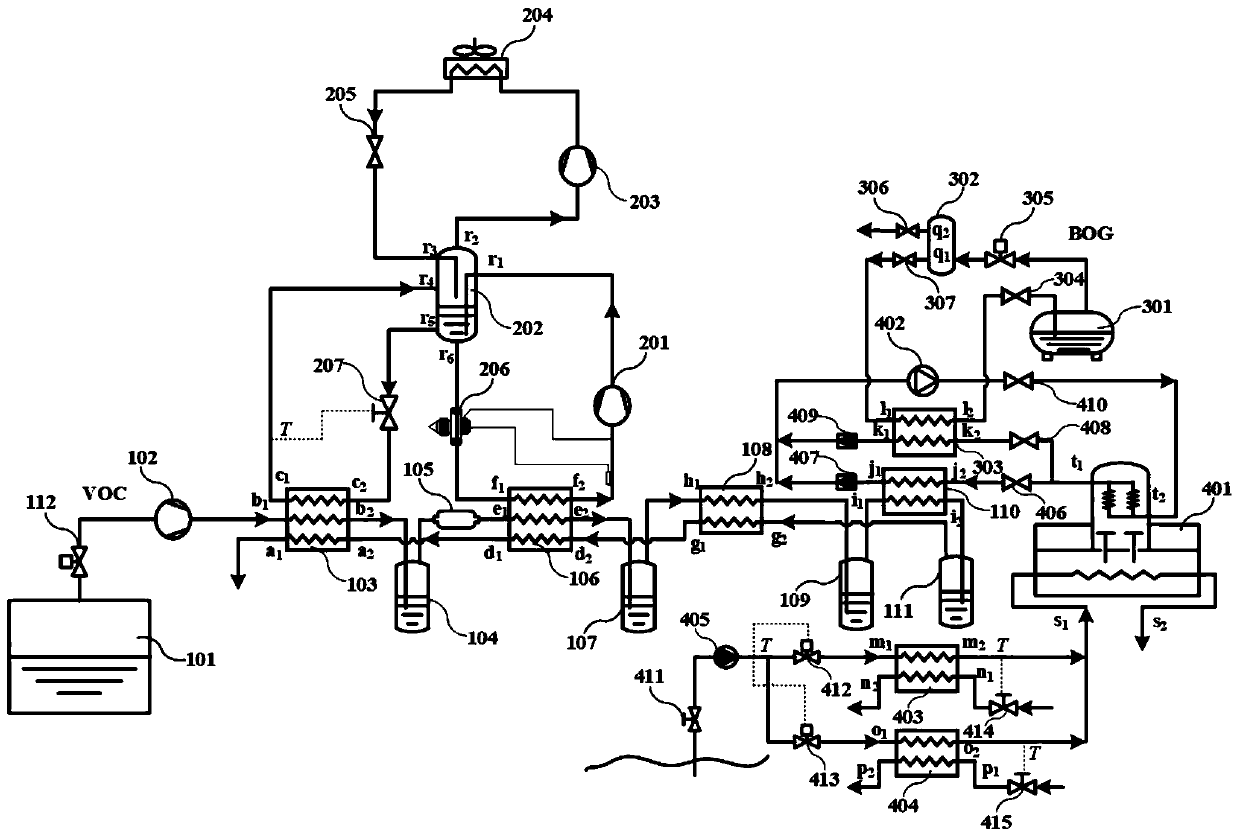

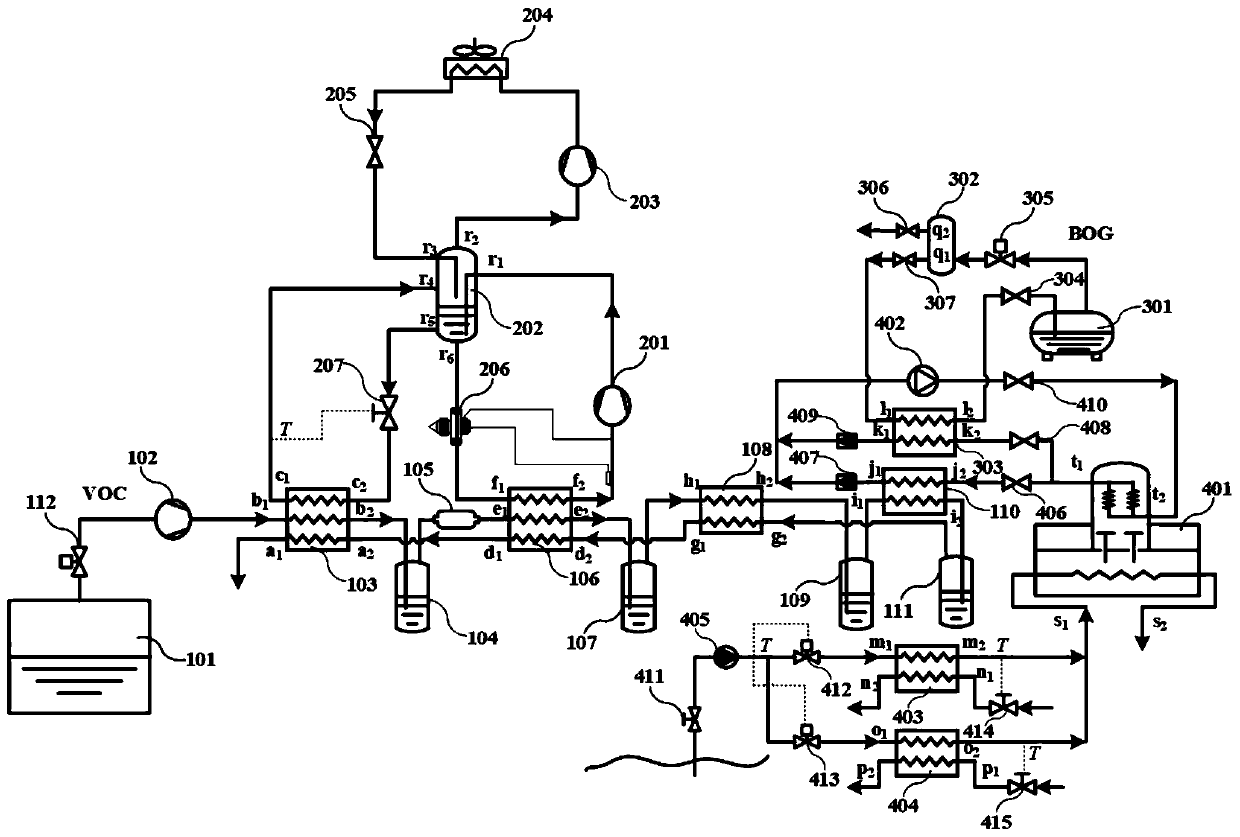

[0034] Such as figure 1 Shown: a marine VOC, BOG comprehensive liquefaction system, including four circulation systems, namely, VOC reliquefaction circulation system, refrigeration circulation system with single working substance, two-stage and double refrigeration temperature, Stirling refrigeration circulation system, and BOG reliquefaction circulation system system, wherein the VOC reliquefaction cycle system includes a cargo oil tank 101, a VOC compressor 102, a first heat exchanger 103, a first gas-liquid separator 104, a drying filter 105, a second heat exchanger 106, a second Two gas-liquid separators 107, the 3rd heat exchanger 108, the 3rd gas-liquid separator 109, the 4th heat exchanger 110, the 4th gas-liquid separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com