9Ni steel fracture fiber rate judgment method

A determination method and fiber technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as the inability to apply 9Ni steel production practices, and achieve the effects of reducing the influence of human factors, high measurement accuracy, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

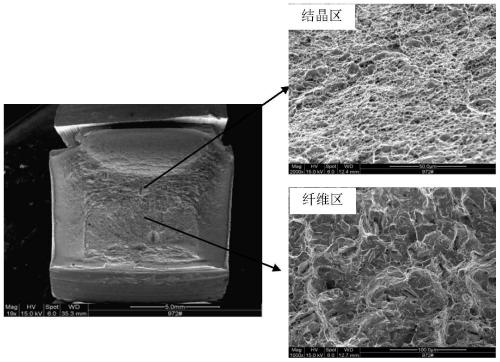

[0038] Using a scanning electron microscope to observe the impact fracture morphology of 9Ni steel with a manually determined fiber rate of 70%, the sample number is 7197-2-1, the impact sample size is 10×10×55mm, and the sample width b=10000μm; see figure 1 , the observed, analyzed and calculated crystallization area S=17191481.50μm 2 , then its fracture fiber rate is:

[0039] FA=[1-S / (a×b)]×100%=78.5%

Embodiment 2

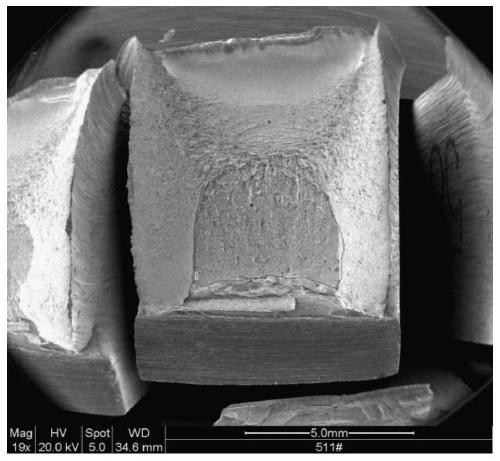

[0041] Use a scanning electron microscope to observe the impact fracture morphology of 9Ni steel with a manually determined fiber rate of 70%, the sample number is 1551-1-1, and the impact sample size is 7.5×10×55mm, then b=7500μm; see figure 2 , the observed, analyzed and calculated crystallization area S=12695980.14μm 2 , then its fracture fiber rate is:

[0042] FA=[1-S / (a×b)]×100%=78.8%

Embodiment 3

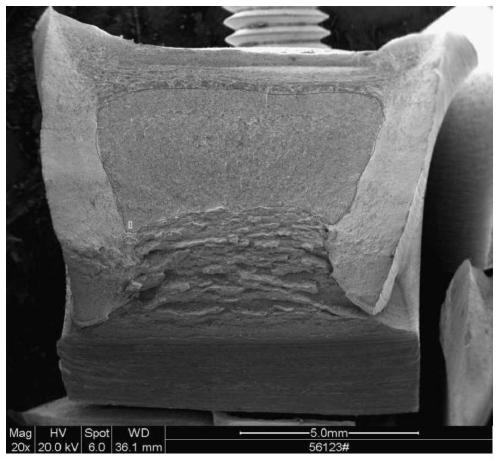

[0044] Use a scanning electron microscope to observe the impact fracture morphology of 9Ni steel with a manually determined fiber ratio of 65%, the sample number is 561-2-3, and the impact sample size is 10×10×55mm, then b=10000; see image 3 , the observed, analyzed and calculated crystallization area S=25084739.84μm 2 , then its fracture fiber rate is:

[0045] FA=[1-S / (a×b)]×100%=68.6%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com