Ultrasonic transducer and ultrasonic ranging module

An ultrasonic and transducer technology, applied in the field of ultrasonic distance measurement, can solve problems that may spread to the fuselage or coin slot, affecting accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An ultrasonic distance measuring module includes a mounting mechanism (not shown) and an ultrasonic transducer, and the ultrasonic transducer is arranged on the mounting mechanism.

[0028] The installation mechanism includes a circuit board and a support plate, the circuit board is arranged on the support plate, at least one positioning element is provided on the circuit board, and a corresponding complementary positioning element is provided on the support plate, the The positioning element is a buckle.

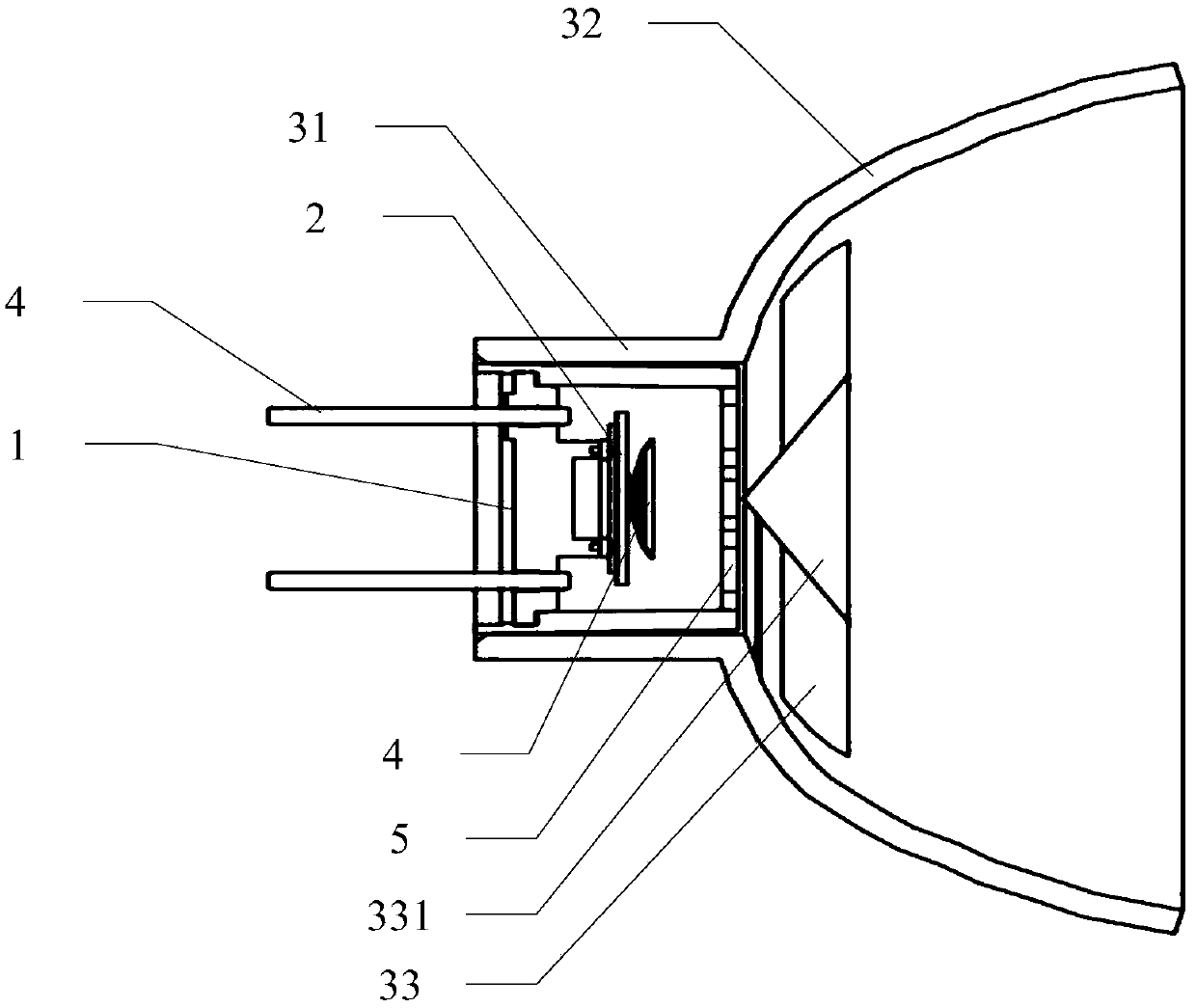

[0029] See figure 1 , the ultrasonic transducer includes a housing, a support ring 1, a piezoelectric wafer 2, pins 3, a tapered resonant disk 4 and a wire mesh cover 5, and the housing includes an accommodating cavity 31, a horn 32 and a phase plug 33, the housing is a horn with a phase plug, the accommodating cavity 31 is connected to the horn 32, the phase plug 33 is set in the horn 32, and the support ring 1 is set in the accommodating cavity 31, one side of th...

Embodiment 2

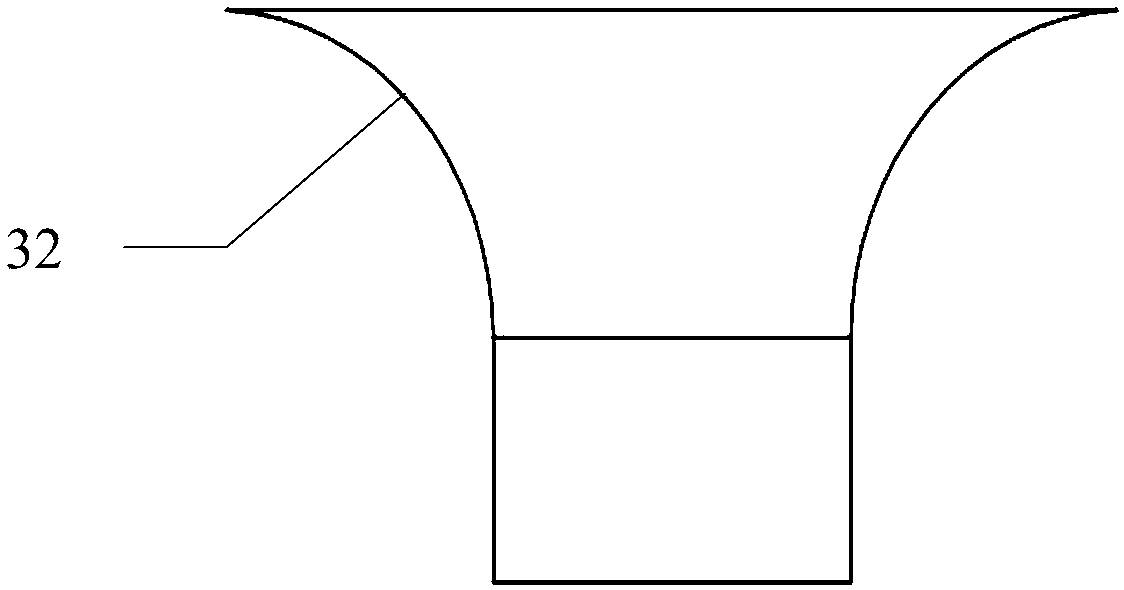

[0040] See image 3 The difference between the second embodiment and the first embodiment is that the horn is basin-shaped and divergent, and the phase plug horn can expand the beam angle of the sound wave to make it detect a wider range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com