Stacked frame electron gun of space traveling wave tube

A traveling wave tube and stacking technology, applied in the field of traveling wave tubes, can solve the problems of poor insulation reliability, large volume, which is not conducive to the miniaturization and light weight of the whole tube, and achieve high structural reliability, reduced size and weight, The effect of reducing bulk and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

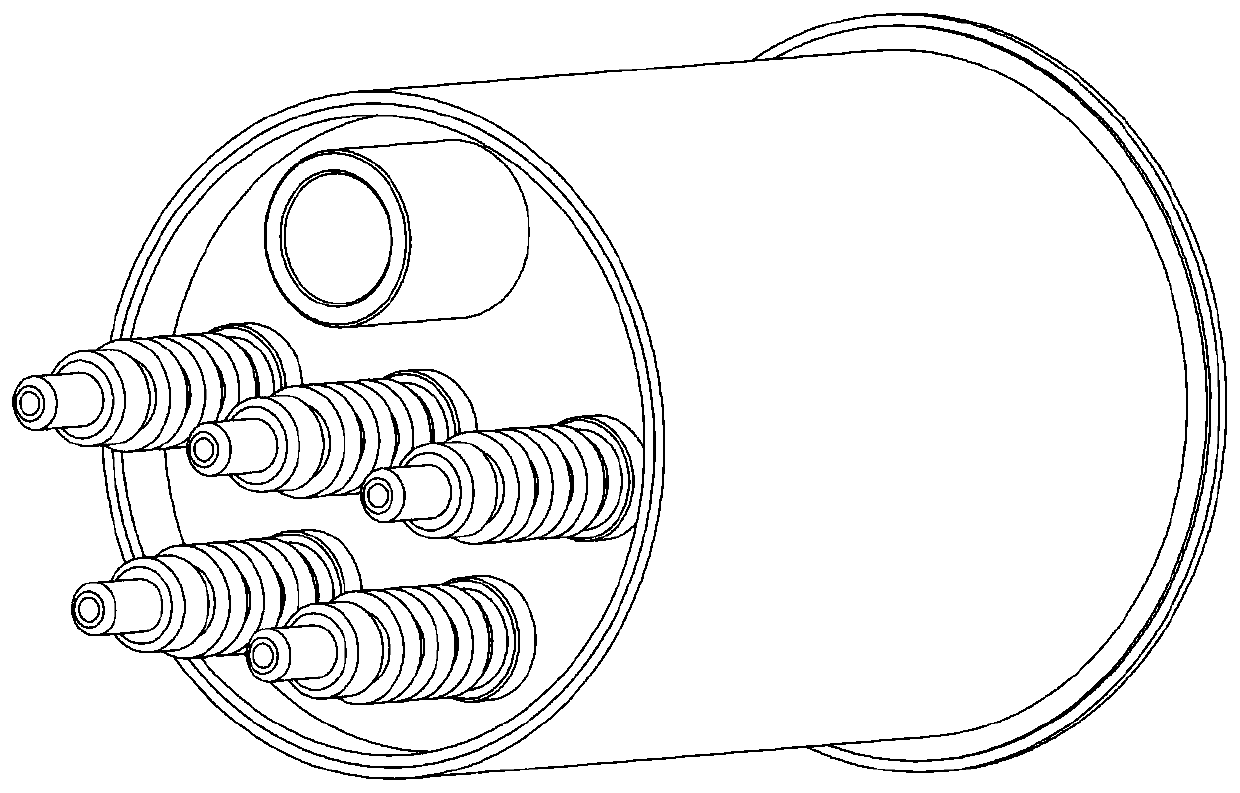

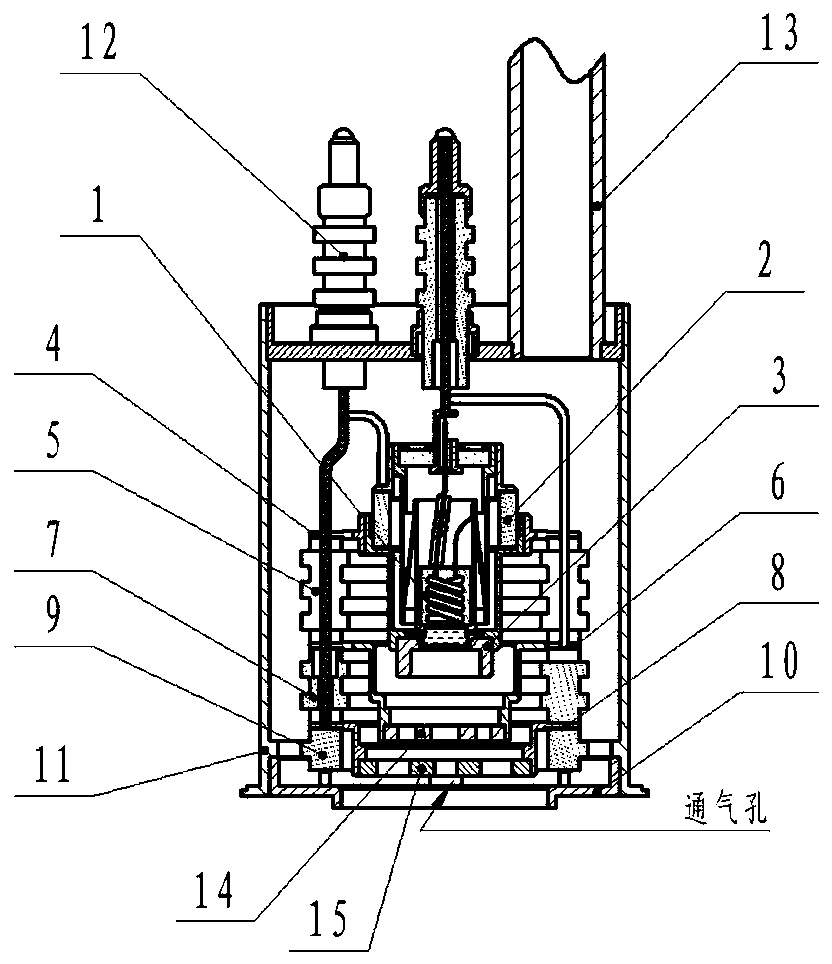

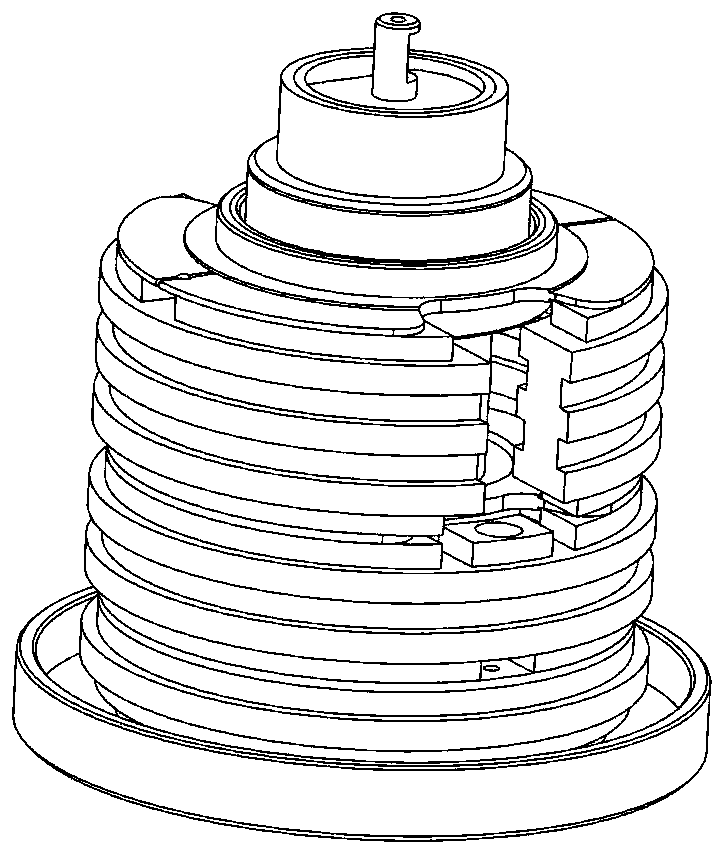

[0020] As shown in 1 to 3, a light-weight and highly reliable stacked frame electron gun of a space traveling wave tube, including a gun core 1, an insulating porcelain cylinder 2, a focusing pole 3, a focusing pole sealing ring 4, and two pieces of semicircular corrugated porcelain 5 rings, a first anode sealing ring 6, a corrugated ceramic ring with holes 7, a second anode sealing ring 8, a corrugated ceramic ring 9, a support seat 10, a metal shell 11, 5 lead wire insulating ceramic columns 12, The first anode 14 and the second anode 15; the focused pole sealing ring 4, the ring, the first anode sealing ring 6, the corrugated ceramic ring 7 with holes, the second anode sealing ring 8, and the corrugated ceramic ring 9 Stacked on the support base 10 from top to bottom, the insulating ceramic cylinder 2 is arranged inside the focusing pole sealing ring 4, the focusing pole 3 is arranged under the insulating porcelain cylinder 2, and the gun core 1 is arranged on the insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com