Dual-barrel type material boiling machine of which inner barrel can be used for accommodating

A technology of inner barrel and container, which is applied in the field of double-barrel cooking machine, which can solve the problems of inconvenient disassembly, low work efficiency, sticking, etc., and achieve the effect of improving connection stability and realizing connection strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

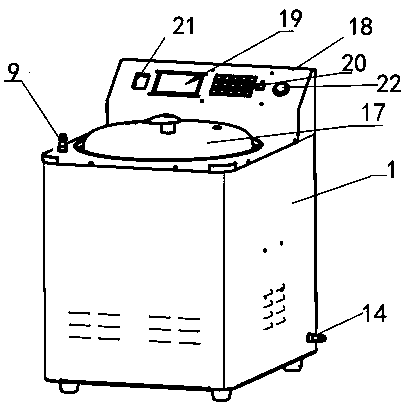

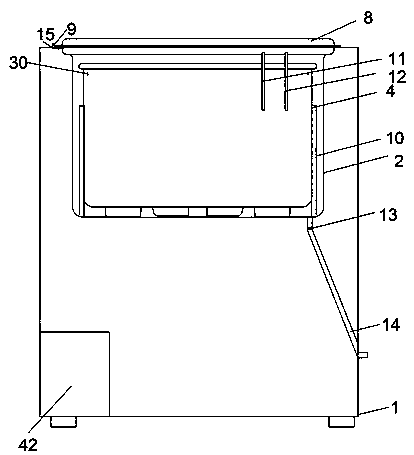

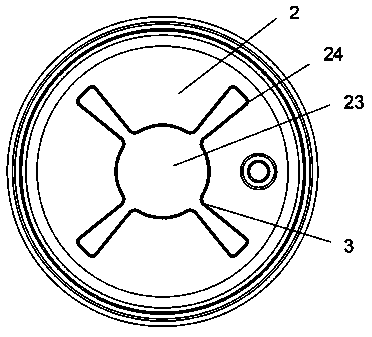

[0031] Such as Figure 1-Figure 7 As shown, the double-barrel cooking machine provided by this embodiment can be used for a double-barrel cooking machine, including a host 1, an outer barrel 2 is provided in the host 1, and a limit groove 3 is provided at the bottom of the outer barrel 2 , a thermally conductive inner barrel 4 is detachably connected to the limit groove 3, and the bottom of the inner barrel 4 is provided with a limit block 6 that cooperates with the limit groove 3, and both sides of the inner side of the inner barrel 4 are provided with The operating handle 7 is provided with an operating cover 8 positioned at the top of the outer barrel body 2 on the top of the main frame 1, and a stirring mechanism extending into the inner barrel body 4 is provided in the operating cover 8. The barrel body 2 penetrates through and is located at the water inlet 9 above the inner barrel body 4, and more than one heating rod 10 is distributed in the outer barrel body 2 relative...

Embodiment 2

[0036] Such as Figure 8 As shown, a kind of inner barrel provided by this embodiment can be used for a double-barrel cooking machine, and further, to improve the connection stability, an electromagnet 27 electrically connected to the controller 42 is also provided on both sides of the bottom of the outer barrel body 2 , both sides of the bottom of the inner barrel body 4 are also provided with magnets 28 that cooperate with the electromagnets 27 to further realize the connection strength and stability between the outer barrel body 2 and the inner barrel body 4.

Embodiment 3

[0038] Such as Figure 9As shown, the inner barrel provided by this embodiment can be used for a double-barrel cooking machine, and further, the agitator 17 includes a first stirring rod 32 and a second stirring rod 33 that are detachably connected to each other. The top of the stirring rod 32 is connected with the stirring motor 16, the thread groove 34 with an internal thread under the first stirring rod 32, and the threaded connection column 35 threadedly connected with the thread groove 34 is provided above the second stirring rod 33, through The first agitating rod 32 and the second agitating rod 33 which are detachably connected are provided to realize the adjustment of the agitating length as required.

[0039] Further, to improve the waterproof effect, a waterproof silicone sleeve 36 is covered at the junction of the first stirring rod 32 and the second stirring rod 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com