A nanotube-shaped cobalt/cobalt tetroxide-based composite catalyst for electrocatalytic hydrogen evolution and its preparation method and application

A technology of cobalt tetroxide-based and composite catalysts, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of large energy consumption, complex preparation methods, chemical process Cumbersome and other problems, to achieve the effect of increasing specific surface area, high catalytic performance, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Unless otherwise specified, the purity of the following drugs are all grade AR.

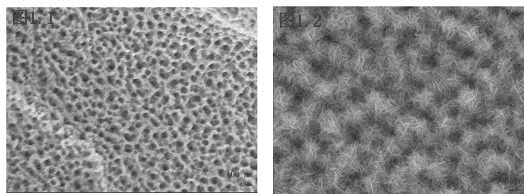

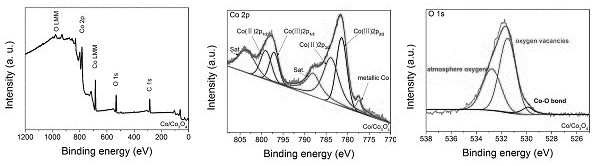

[0044]Weigh 0.1852g of ammonium fluoride and place it in a beaker, add 10mL of deionized water and sonicate for 10min to dissolve it completely. Then add 40mL of ethylene glycol and stir in a 40°C water bath for 35min to mix the ethylene glycol and ammonium fluoride aqueous solution evenly. The treated cobalt sheet is placed on the anode (working area is 1*1cm), the platinum sheet is placed on the cathode (working area is 1*3.5cm), and the distance is 4.2-4.5cm. A voltage of 60V was applied and reacted for 10 min with slight stirring to prepare a cobalt / cobalt tetroxide substrate. The prepared substrate was rinsed several times in absolute ethanol to wash away the residual ethylene glycol on the surface, and then placed in an oven at 60°C to dry it.

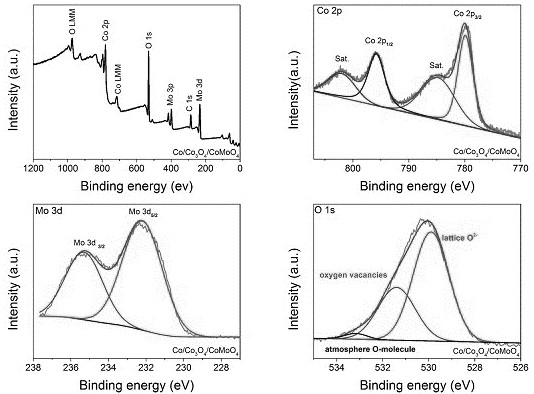

[0045] Weigh 0.38712g of sodium molybdate dihydrate and place it in a beaker, add 80mL of deionized water, and then ultrasonicate for 15mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com