Efficient medicine grinding device

A drug and equipment technology, applied in the field of high-efficiency drug grinding equipment, can solve the problems of high energy consumption, waste of labor costs, waste of drugs, etc., and achieve the effect of increasing the contact area, avoiding small force, and reducing local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

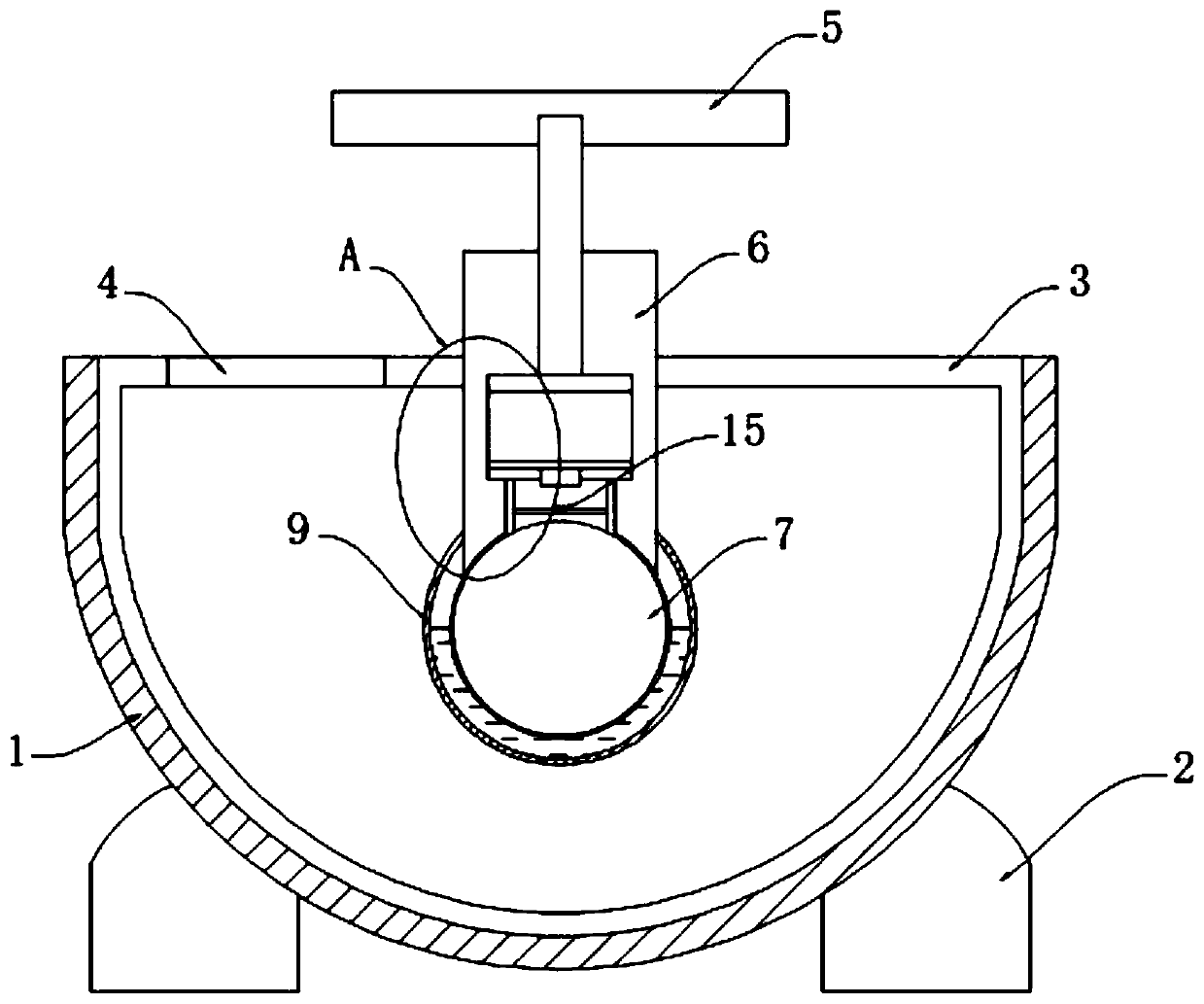

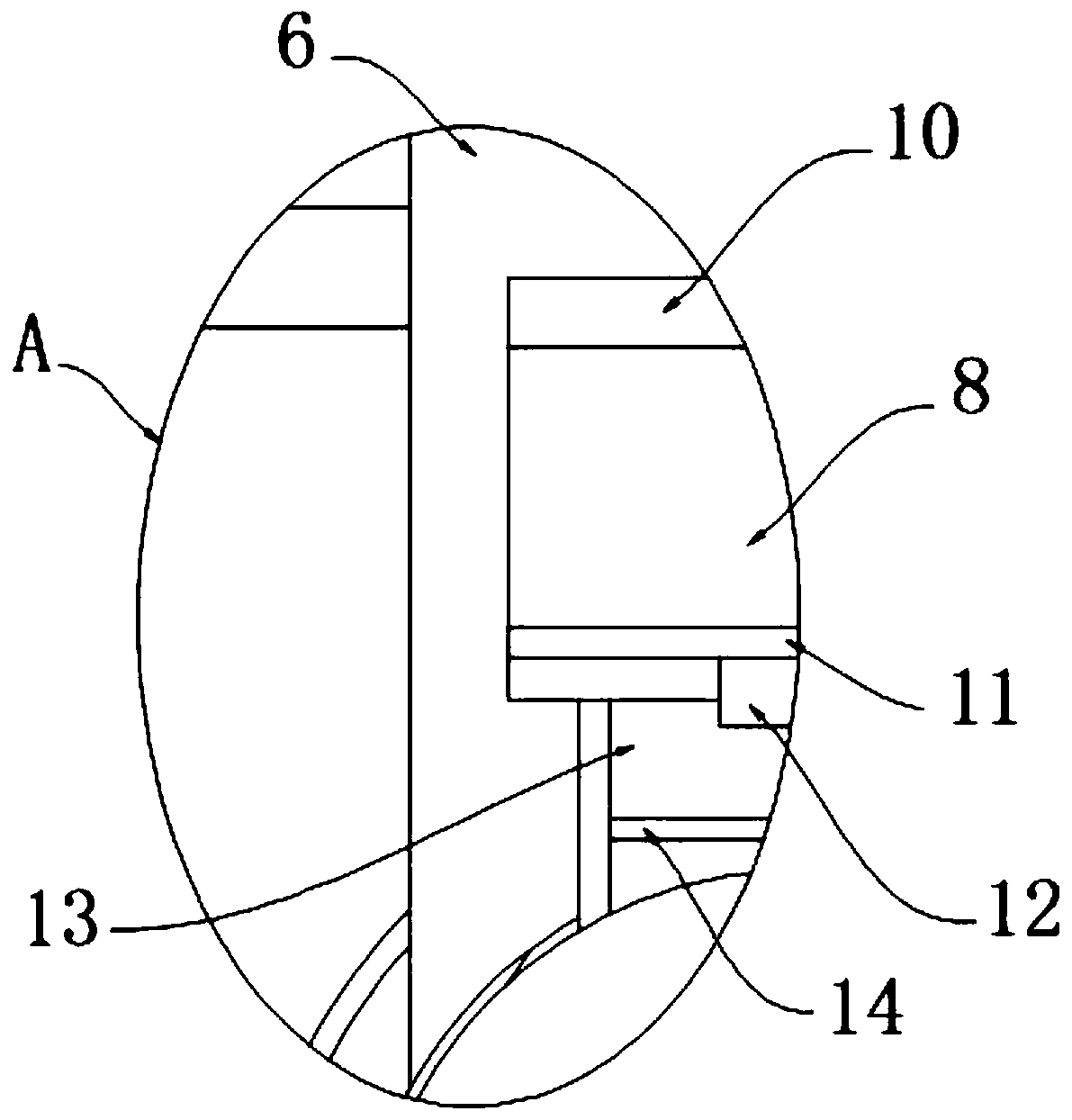

[0019] refer to Figure 1-2 , a high-efficiency drug grinding equipment, including a body 1 and a base 2, the inner wall of the body 1 is rotatably connected with a casing 3, the top of the casing 3 is connected with a rotary drum 6 with sealing threads at the center of rotation, and the inner wall of the rotary drum 6 is provided with a sliding chamber 8 , the slide chamber 8 is sealed and slidably connected with a slide plate 10, the top of the slide plate 10 is fixedly connected with a push rod, the top of the push rod is fixedly connected with a pressure plate 5, the bottom of the drum 6 is welded with a grinding ball 7, and the outer wall of the grind ball 7 is sleeved with a rubber sleeve 9 , magnetorheological fluid is housed in the rubber sleeve 9. The top of the casing 3 is provided with a feed port and the feed port is sealed and rotatably connected with a feed plate 4;

[0020] The rubber sleeve 9 has a bag-like structure and is mutually sealed. Conductor plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com