Numerically-controlled full-automatic machining center for precise hardware

A technology of automatic machines and machining centers, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increased production costs, low production efficiency, processing position deviation, etc., and achieves a high degree of automation and compaction efficiency. High, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

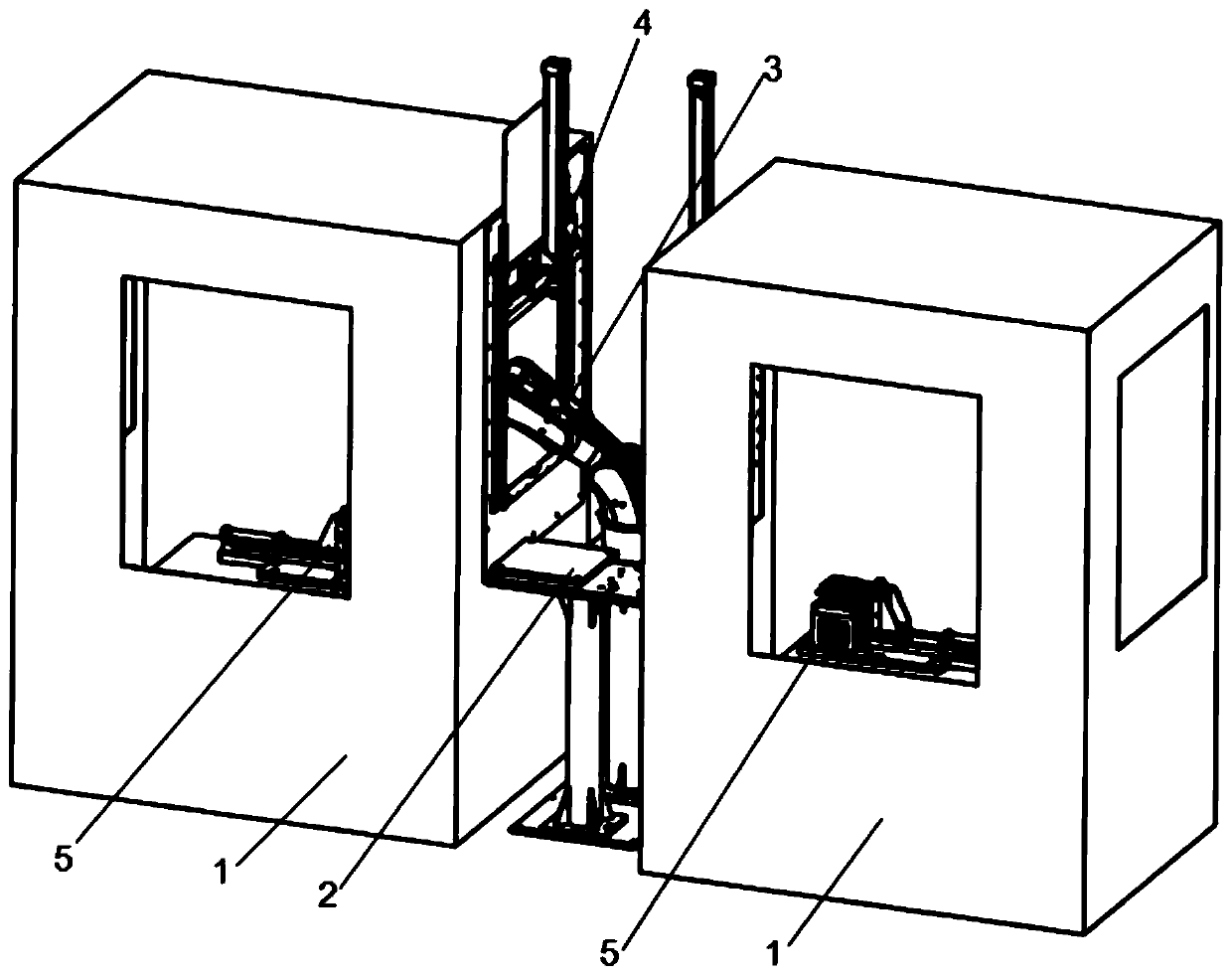

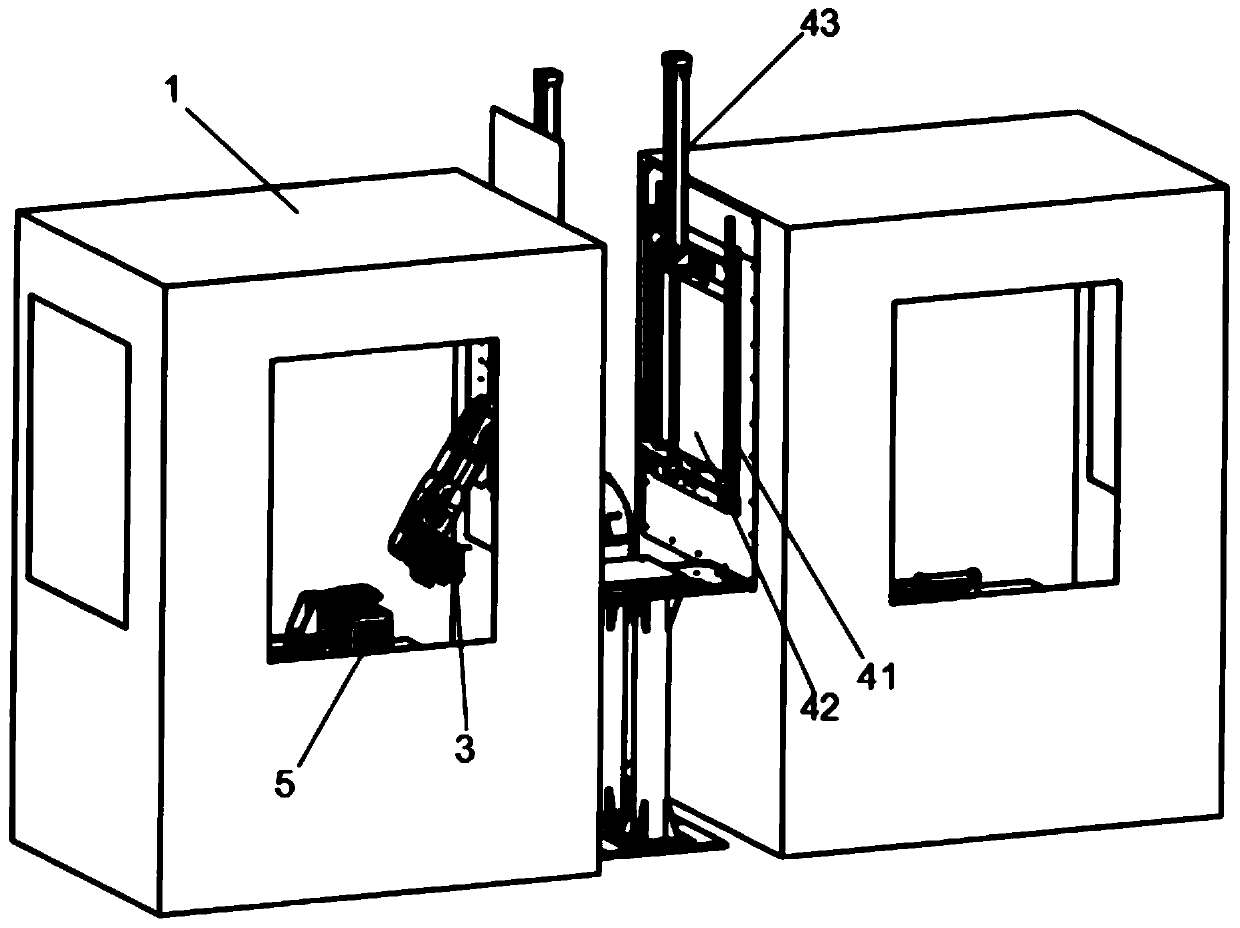

[0039] Embodiment: A numerically controlled fully automatic machining center for precision hardware.

[0040] refer to Figure 1 to Figure 14 As shown, a CNC fully automatic machining center for precision hardware, including:

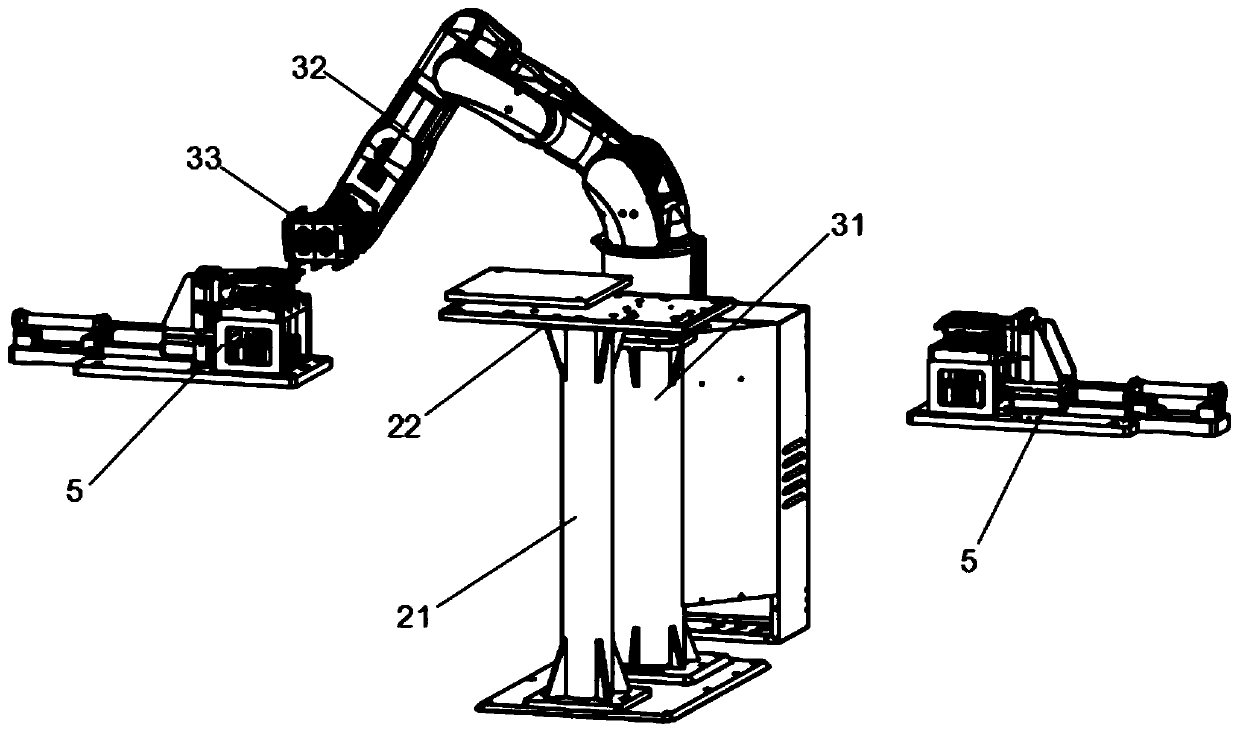

[0041] The feeding manipulator 3 includes a base 31 on which a mechanical arm 32 is installed. The front end of the mechanical arm 32 is equipped with a mechanical gripper 33, wherein the mechanical arm 32 is KUKA KR210 type Rotating arm, described mechanical gripper 33 comprises frame 331, and described frame 331 rear end is provided with docking rotating shaft 332, and frame 331 is connected with mechanical arm by docking rotating shaft 332, is convenient to the integral rotation of frame 331, and described machine The upper end and the lower end of the frame 331 are equipped with two rows of symmetrically arranged fixed jaw blocks 335, and each row is provided with three fixed jaw blocks 335, which can realize grabbing six hardware at one time. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com