A kind of titanium carbon based cold tamping material and its preparation method and application

A technology of titanium carbon and raw materials, which is applied in the field of titanium carbon-based cold tamping materials and its preparation, can solve the problems of health hazards for operators, unsatisfactory sintering of material surfaces, and large heat loss in smelting, so as to improve the working environment and reduce labor intensity. The effect of reducing and prolonging the furnace life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Titanium carbon-based cold tamping material, its raw materials and parts by weight are 55% high-titanium slag, 10% foamed benzene plate particles, 10% crushed graphite, 3% rutile, 2% titanium carbide, 5% boric acid, humic acid Na2SO4 15%; the particle size of the particles in the high titanium slag is 10-15mm, the particle size is 5-10mm, the particle size is 1-5mm and the particle size is the weight fraction below 200 mesh The ratio is 2:1:1:2; the particle size of the crushed graphite is 15-25mm.

[0019] The preparation method of titanium carbon-based cold tamping material, the specific steps are as follows: high-titanium slag, foamed benzene plate, rutile, titanium carbide and graphite crushed into different particle sizes required, after mixing, add binder and boric acid, Put it in a strong stirring pot, 30 rpm, and stir for 30 minutes, so that the materials can stick together through knotting or tamping. The state is the best, and the material can be discharged. ...

Embodiment 2

[0021] Titanium carbon-based cold tamping material, its raw materials and parts by weight are 56% high titanium slag, 8% foamed benzene plate particles, 9% crushed graphite, 2.5% rutile, 2.5% titanium carbide, 6% boric acid, phosphoric acid 16%.

Embodiment 3

[0023] Titanium carbon-based cold tamping material, its raw materials and their weight parts are 60% high-titanium slag, 5% foamed benzene plate particles, 5% graphite crushed, 2% rutile, 2% titanium carbide, 8% boric acid, ring Oxygen resin 18%.

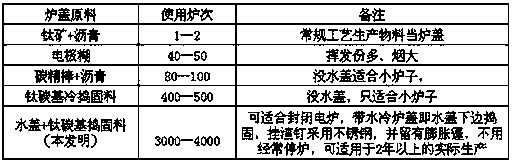

[0024] In order to further study the service life of the furnace cover prepared by the cold tamping material of the present invention, the existing materials were used to tamp the furnace cover, and after long-term smelting, the furnaces with damage to the furnace cover were counted. The results are shown in Table 1.

[0025] Table 1 Statistical results of the use of furnace covers for five kinds of materials cold tamped.

[0026]

[0027] It can be seen that the furnace cover protective layer made of the tamping material of the present invention has a longer service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com