Modular trolley for carrying rail detection equipment

A track detection and modularization technology, applied in railway inspection vehicles, railway auxiliary equipment, railway car body parts, etc., can solve the problems of manual transportation to the subway track and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0078] Example.

[0079] see Figure 1 to Figure 24 .

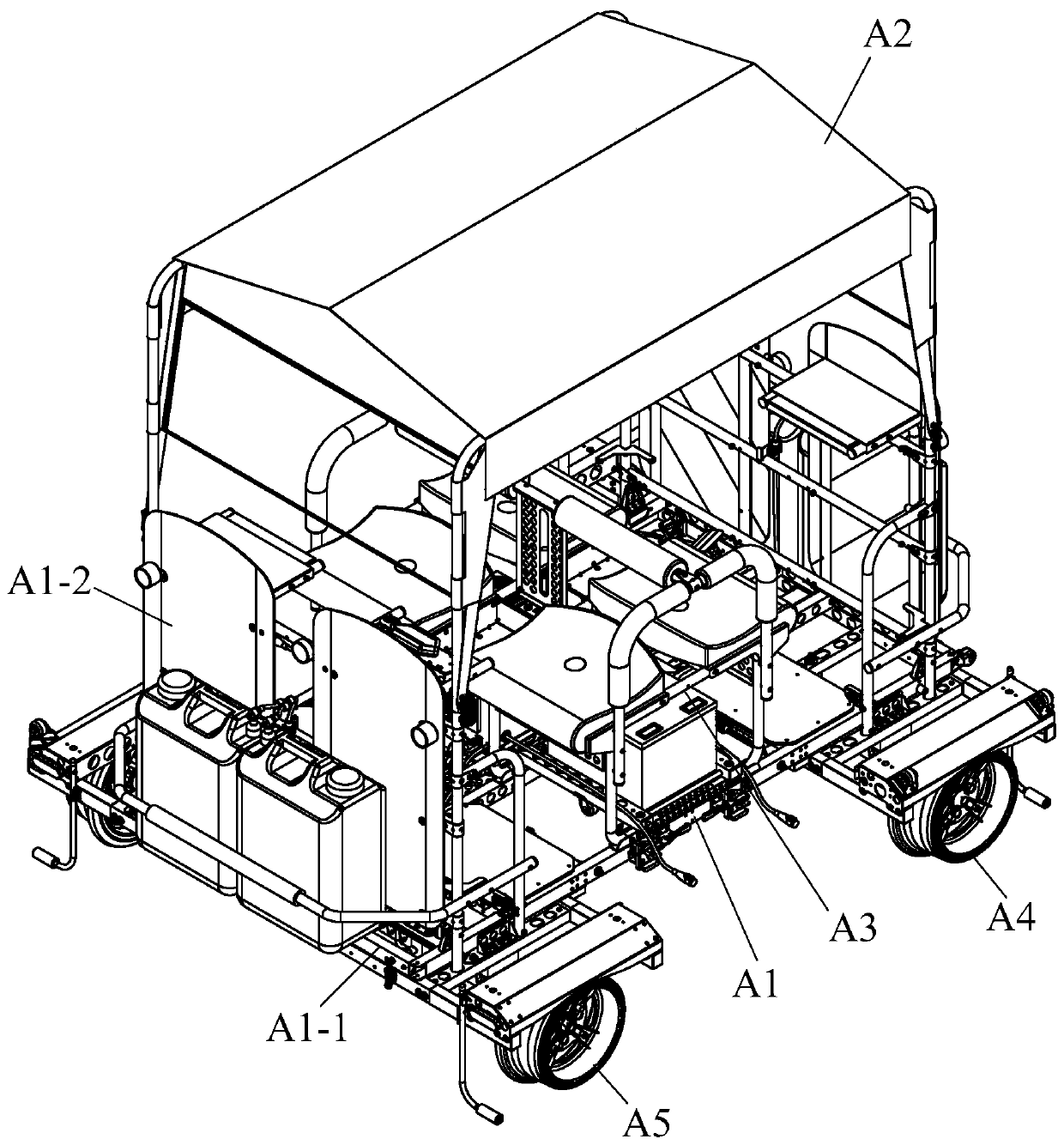

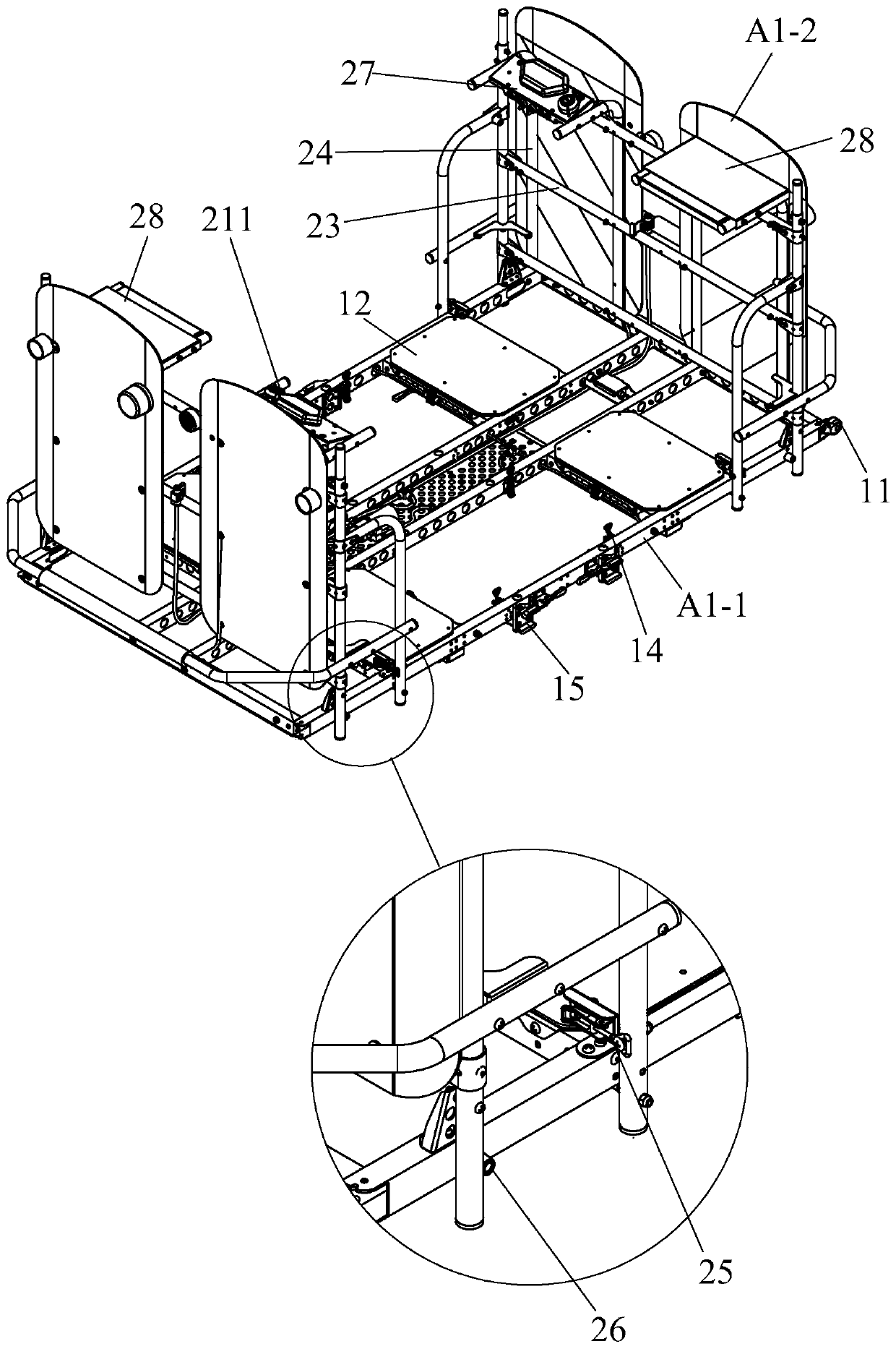

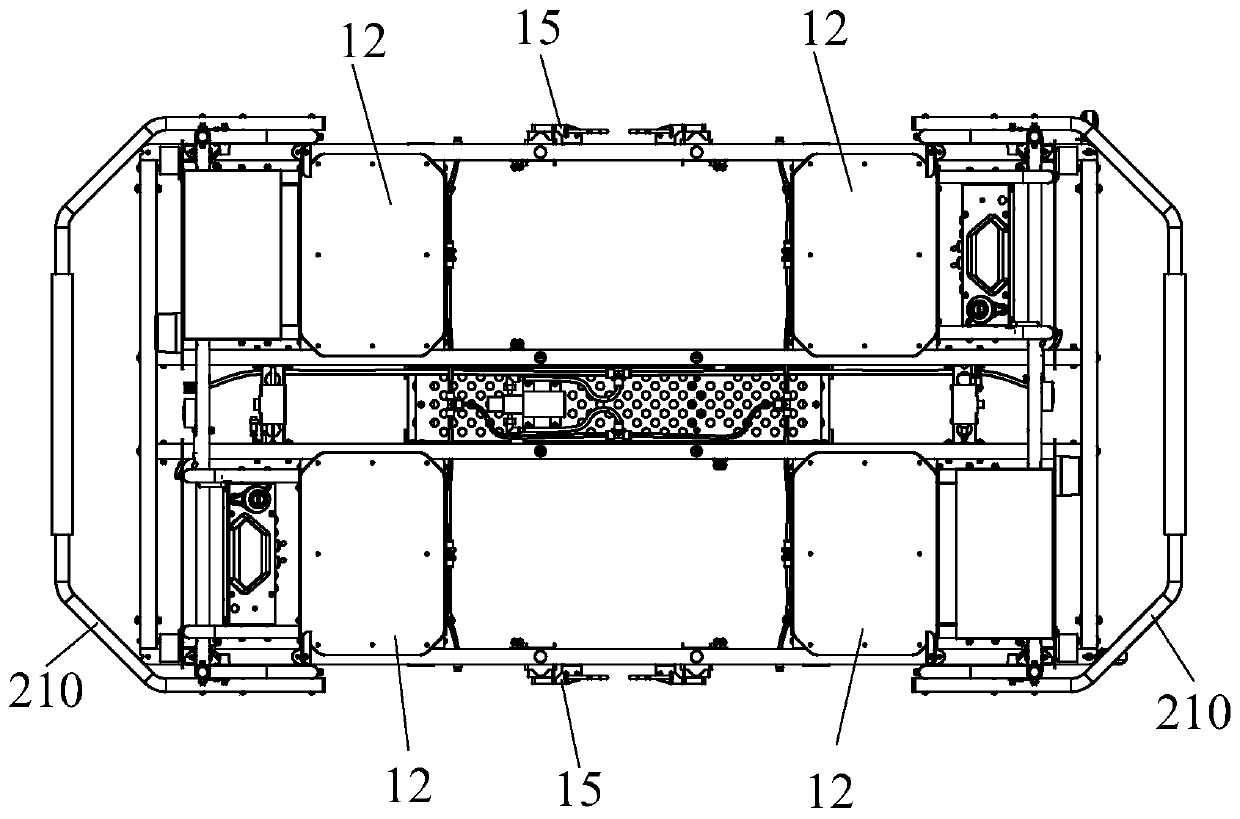

[0080] This embodiment discloses a modular trolley for carrying track detection equipment. The modular trolley includes a body module A1, a seat module A3, a front axle module A4, a rear axle module A5, a roof module A2, a control box A9 and Battery module A7. Each module weighs no more than 60kg.

[0081] In this embodiment, the seat module A3 is detachably installed on the body module A1; both the front axle module A4 and the rear axle module A5 can be detachably installed under the body module A1, wherein the front axle module A4 is an active power module, which includes a drive The motor 44 makes the modular trolley run on the detection track through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com