A colored polyester deodorizing fiber

A colored polyester and fiber technology, applied in the fiber field, can solve the problems that colored polyester fibers do not have deodorizing function and cannot meet people's deodorization needs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

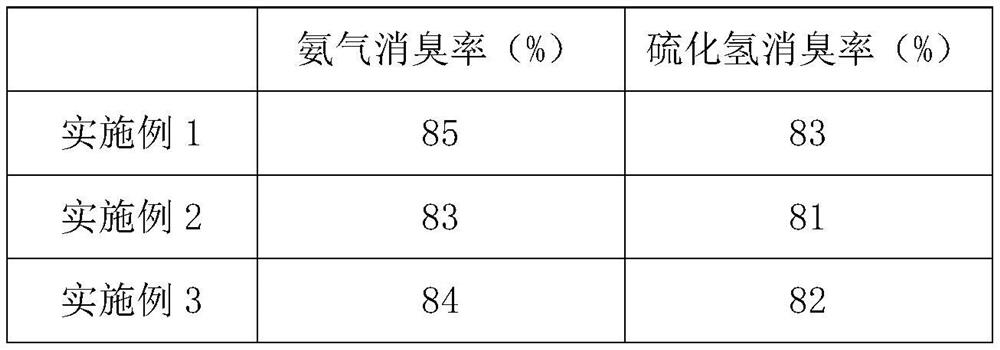

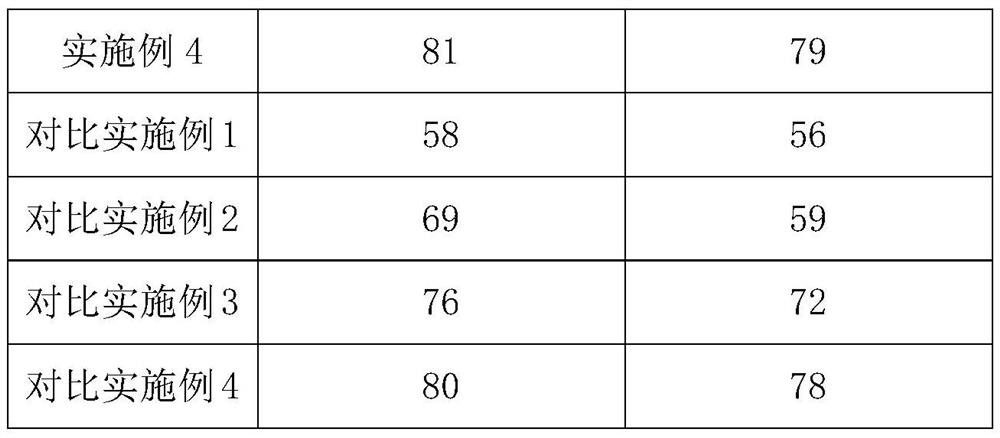

Examples

Embodiment 1

[0023] Follow the steps below to prepare colored polyester deodorant fibers:

[0024] (1) diethylenetriamine is added in the there-necked flask, ice-water bath, pass N 2 Under the protection, methyl acrylate and methanol were added dropwise, and after the dropwise addition was completed, the monomer was reacted at room temperature for 4 hours to obtain the monomer. The monomer was transferred to the eggplant-shaped flask on the rotary evaporator, and the methanol was evaporated under reduced pressure. Stop the reaction to obtain an amino-terminated hyperbranched polyamidoamine, wherein the mol ratio of diethylenetriamine, methyl acrylate and methanol is 1:15:7;

[0025] (2) Add the amino-terminated hyperbranched polyamidoamine obtained in step (1) into ethanol, stir until it is completely dissolved to obtain a polyamidoamine solution, add sodium acrylate to the polyamidoamine solution at 10°C, heat up to 90°C and react for 12 hours , after cooling to room temperature, carboxy...

Embodiment 2

[0030] Follow the steps below to prepare colored polyester deodorant fibers:

[0031] (1) diethylenetriamine is added in the there-necked flask, ice-water bath, pass N 2 Under the protection, methyl acrylate and methanol were added dropwise, and after the dropwise addition was completed, the monomer was reacted at room temperature for 4 hours to obtain the monomer. The monomer was transferred to the eggplant-shaped flask on the rotary evaporator, and the methanol was evaporated under reduced pressure. Stop the reaction to obtain an amino-terminated hyperbranched polyamidoamine, wherein the mol ratio of diethylenetriamine, methyl acrylate and methanol is 1:15:7;

[0032] (2) Add the amino-terminated hyperbranched polyamidoamine obtained in step (1) into ethanol, stir until it is completely dissolved to obtain a polyamidoamine solution, add sodium acrylate to the polyamidoamine solution at 10°C, heat up to 90°C and react for 12 hours , after cooling to room temperature, carboxy...

Embodiment 3

[0037] Follow the steps below to prepare colored polyester deodorant fibers:

[0038] (1) diethylenetriamine is added in the there-necked flask, ice-water bath, pass N 2 Under the protection, methyl acrylate and methanol were added dropwise, and after the dropwise addition was completed, the monomer was reacted at room temperature for 4 hours to obtain the monomer. The monomer was transferred to the eggplant-shaped flask on the rotary evaporator, and the methanol was evaporated under reduced pressure. Stop the reaction to obtain an amino-terminated hyperbranched polyamidoamine, wherein the mol ratio of diethylenetriamine, methyl acrylate and methanol is 1:15:7;

[0039] (2) Add the amino-terminated hyperbranched polyamidoamine obtained in step (1) into ethanol, stir until it is completely dissolved to obtain a polyamidoamine solution, add sodium acrylate to the polyamidoamine solution at 10°C, heat up to 90°C and react for 12 hours , after cooling to room temperature, carboxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com