Elevated stereoscopic cold storage based on grid structure

A technology of grid structure and cold storage, which is applied in coolers, freezing plants, refrigeration rooms, etc., can solve the problems of inconvenient assembly, low assembly accuracy, and difficult construction, and reduce the difficulty of construction management and quality control. Good performance and integrity, and the effect of increasing the storage space of the cold storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

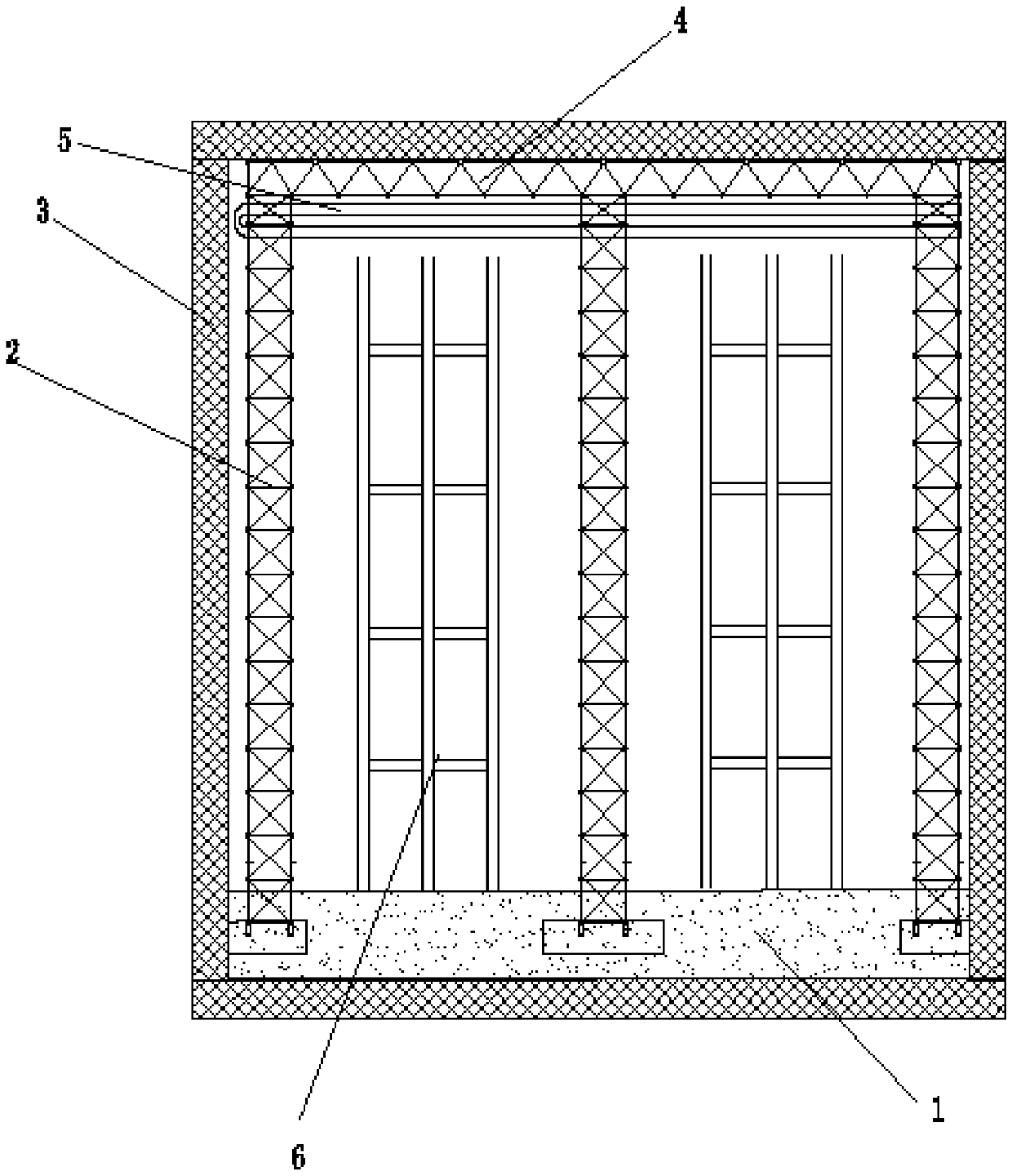

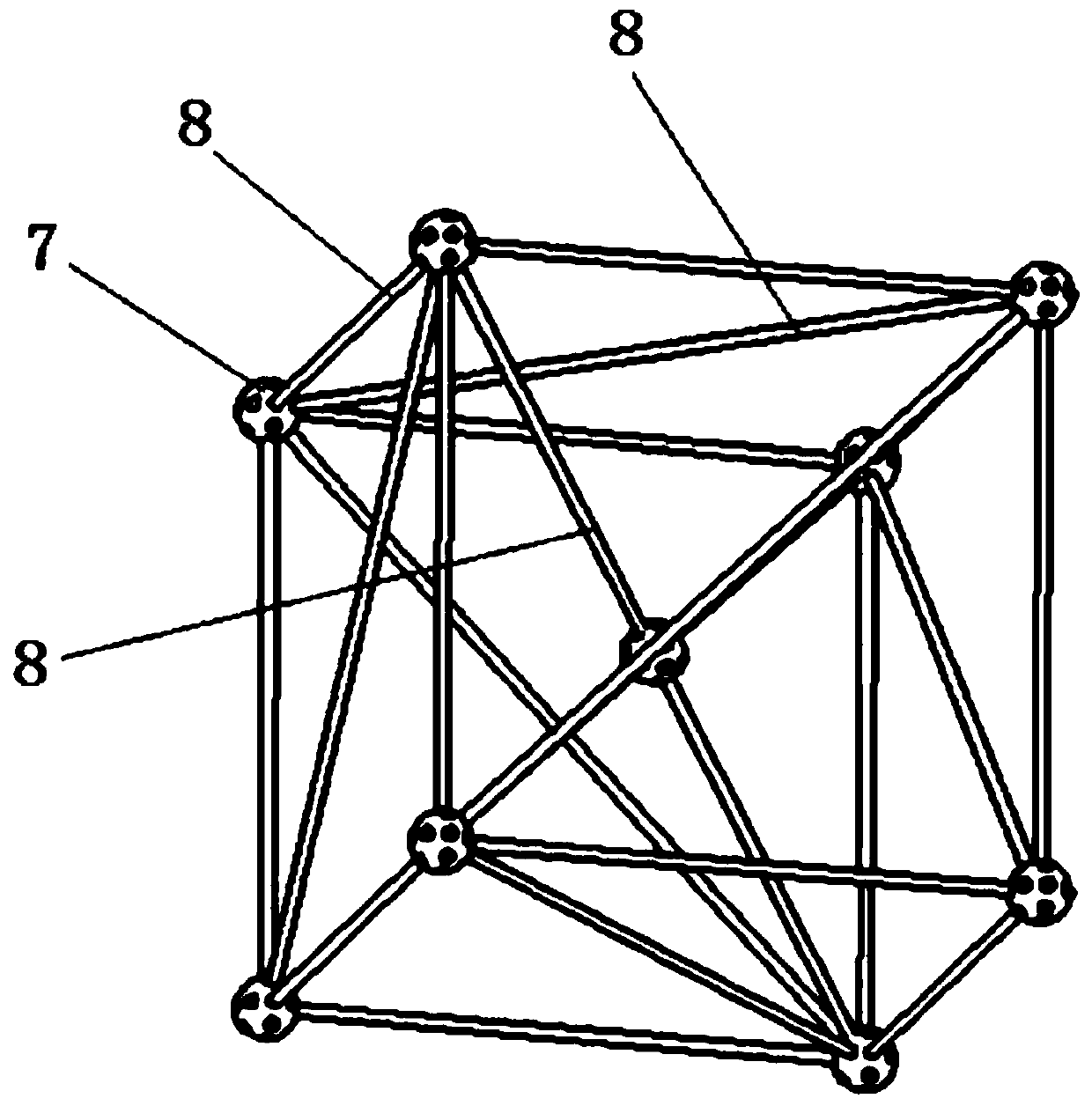

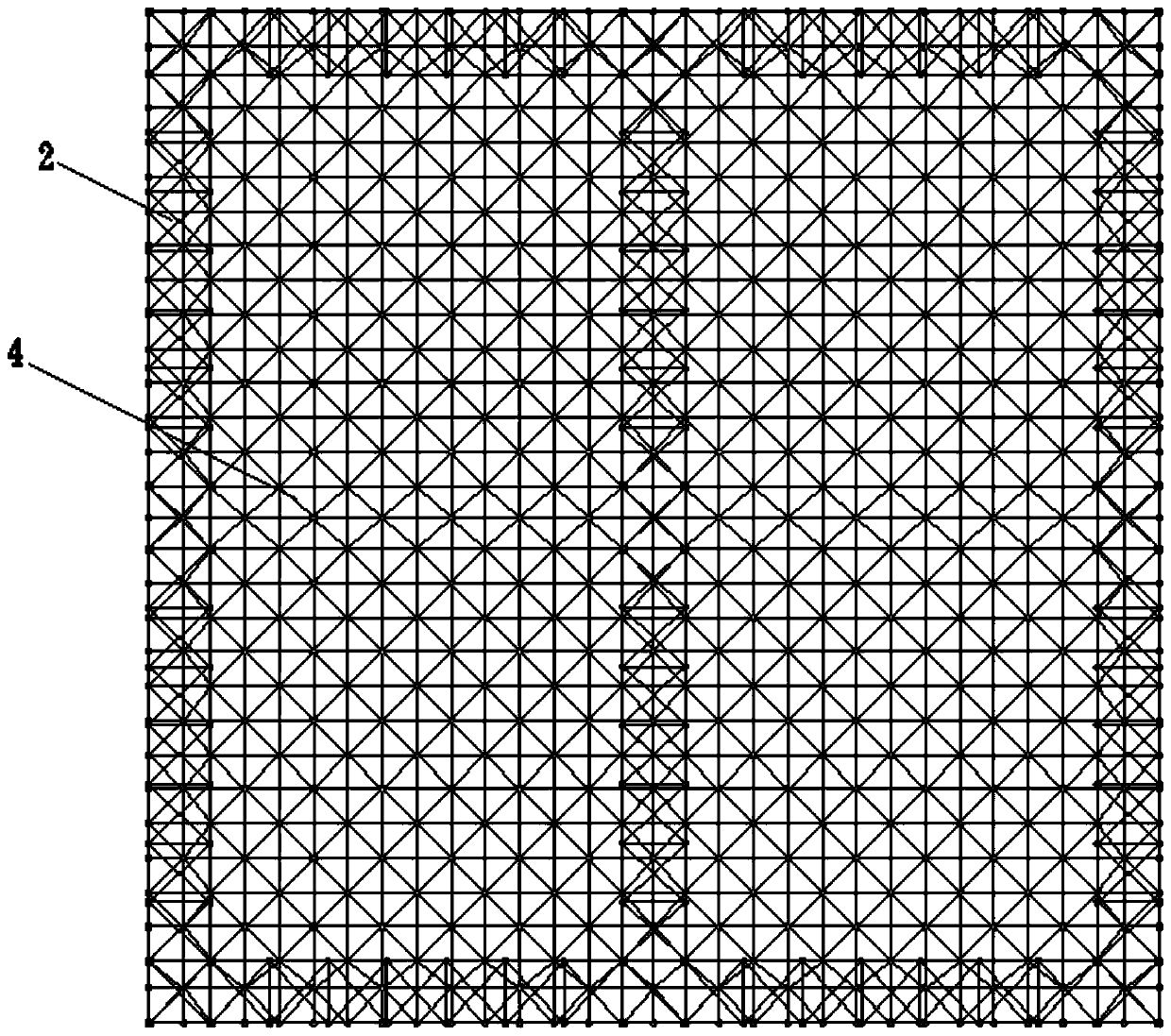

[0032] The load-bearing column 2 of the existing elevated three-dimensional cold storage adopts a truss structure, and the truss structure has many construction defects and high cost. The present invention provides another elevated three-dimensional cold storage with a load-bearing column 2 structure. see Figure 1 to Figure 3 As shown, the elevated three-dimensional cold storage based on the grid structure provided in this embodiment includes a raft foundation 1, a thermal insulation structure 3 and a load-bearing column 2, see figure 1 As shown, the hexahedron of the cold storage is provided with a complete and continuous thermal insulation structure 3, the load-bearing column 2 is fixed on the raft foundation 1, and the load-bearing column 2 includes a plurality of grid units connected in sequence, and the grid The frame unit includes a connecting piece 7 and a connecting rod 8 connecting the connecting piece 7, and a plurality of network frame units are sequentially connec...

Embodiment 2

[0043] On the basis of embodiment 1, the elevated three-dimensional cold storage based on grid structure provided by this embodiment, see Figure 4 As shown, the cargo access passage 9 is provided with a double interlocking door 10 . When the goods come in and out, the existing cold storage door structure, the goods are easy to wait outside the door, resulting in accumulation, resulting in low work efficiency, which will cause a large amount of cold storage in the cold storage to leak out. Therefore the present embodiment adopts the double-track interlocking door 10 structure, and when goods enter the front door, close the back door; The conveying motor drives the conveyor belt to send the goods into the cold storage behind the last door; when the goods leave the warehouse, you can open the second door first, close the latter door after the goods enter the conveyor belt in front of the last door, and then open the front door A door transports the goods out, thus forming a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com