Magnetic levitation vertical shaft disc type coreless wind driven generator

A wind power generator and magnetic levitation technology, which is applied in wind power generators, wind power generators at right angles to the wind direction, combination of wind power motors, etc., can solve problems such as high loss, lack of heat dissipation measures and shock absorption measures, and reduced service life of motors , to achieve the effects of convenient manufacture, easy start-up with breeze, and low eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

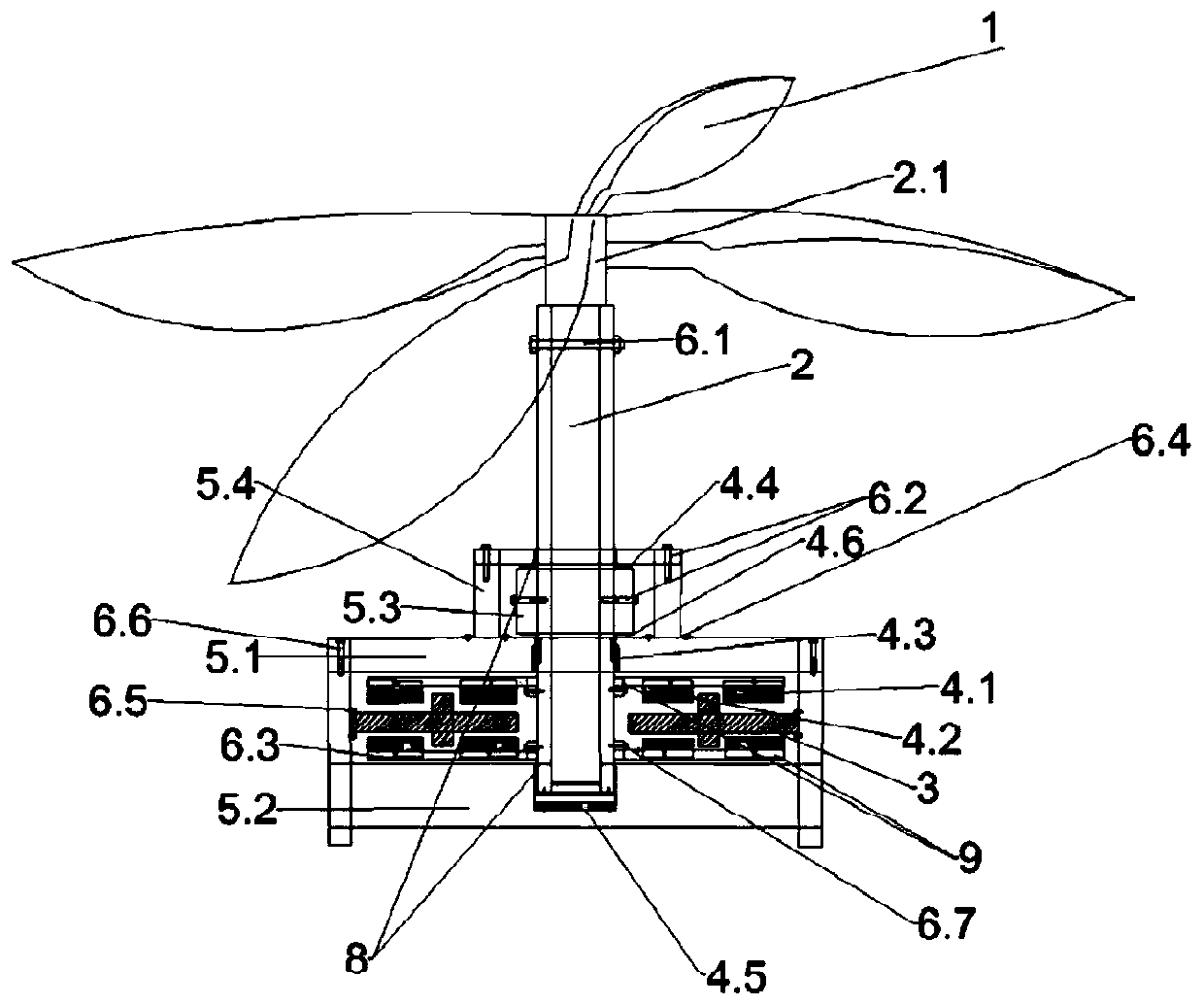

[0034] Such as figure 1 As shown, a magnetic levitation vertical shaft disk coreless wind power generator in this embodiment includes a blade device, a stator device and a rotor device; the blade device includes a blade shaft 2.1 and a blade 1 fixed on the top of the blade shaft 2.1; In this embodiment, the blade 1 is ear-shaped and fixed on the blade shaft 2.1 by bolts. The blade 1 is made of FRP composite material and made into four twisted blades. There is a certain space in the middle of the blades; compared with traditional blades, ear-shaped blades It has the characteristics of large positive force area and small reverse force area, so it has the advantage of large rotational torque.

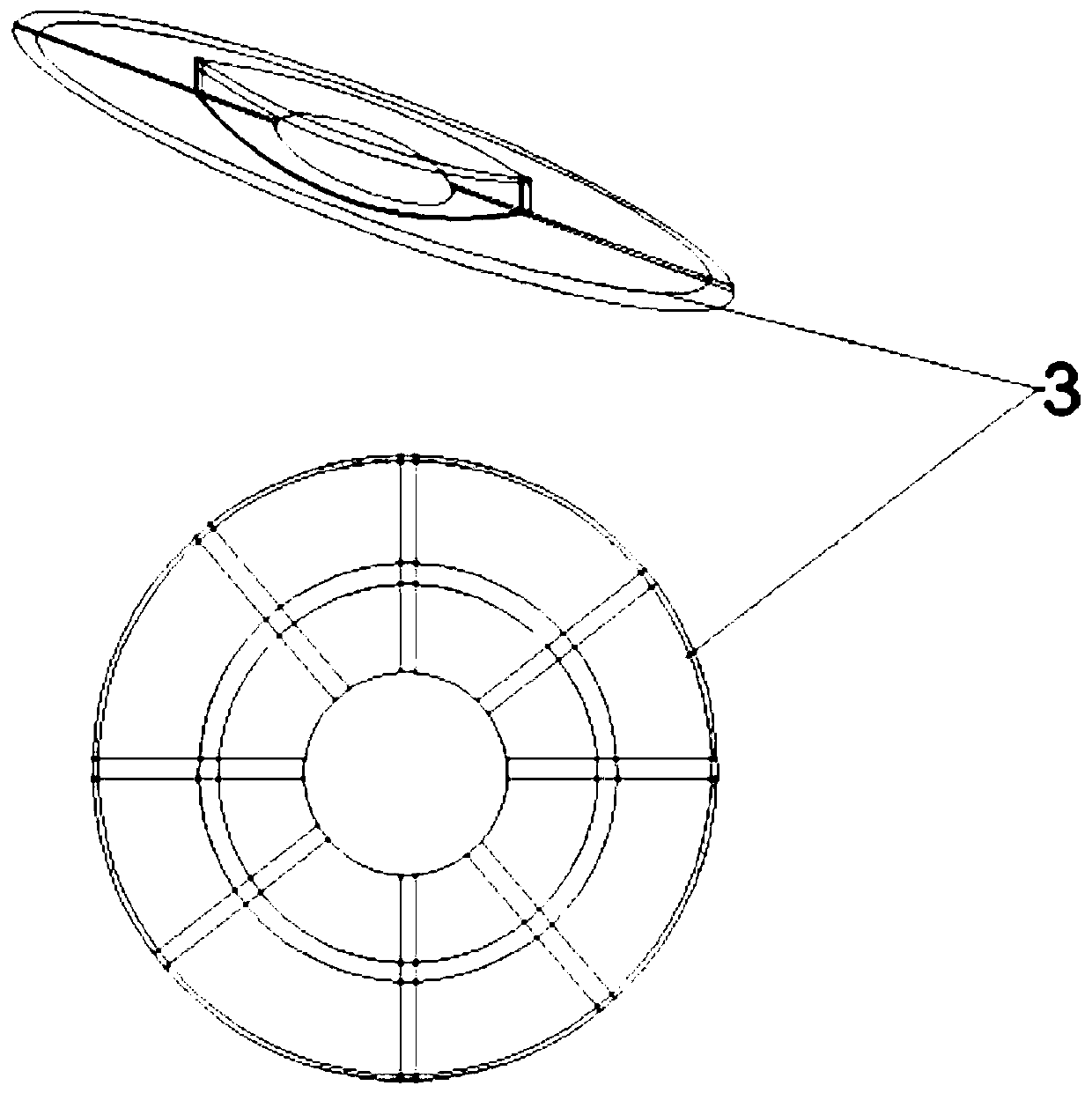

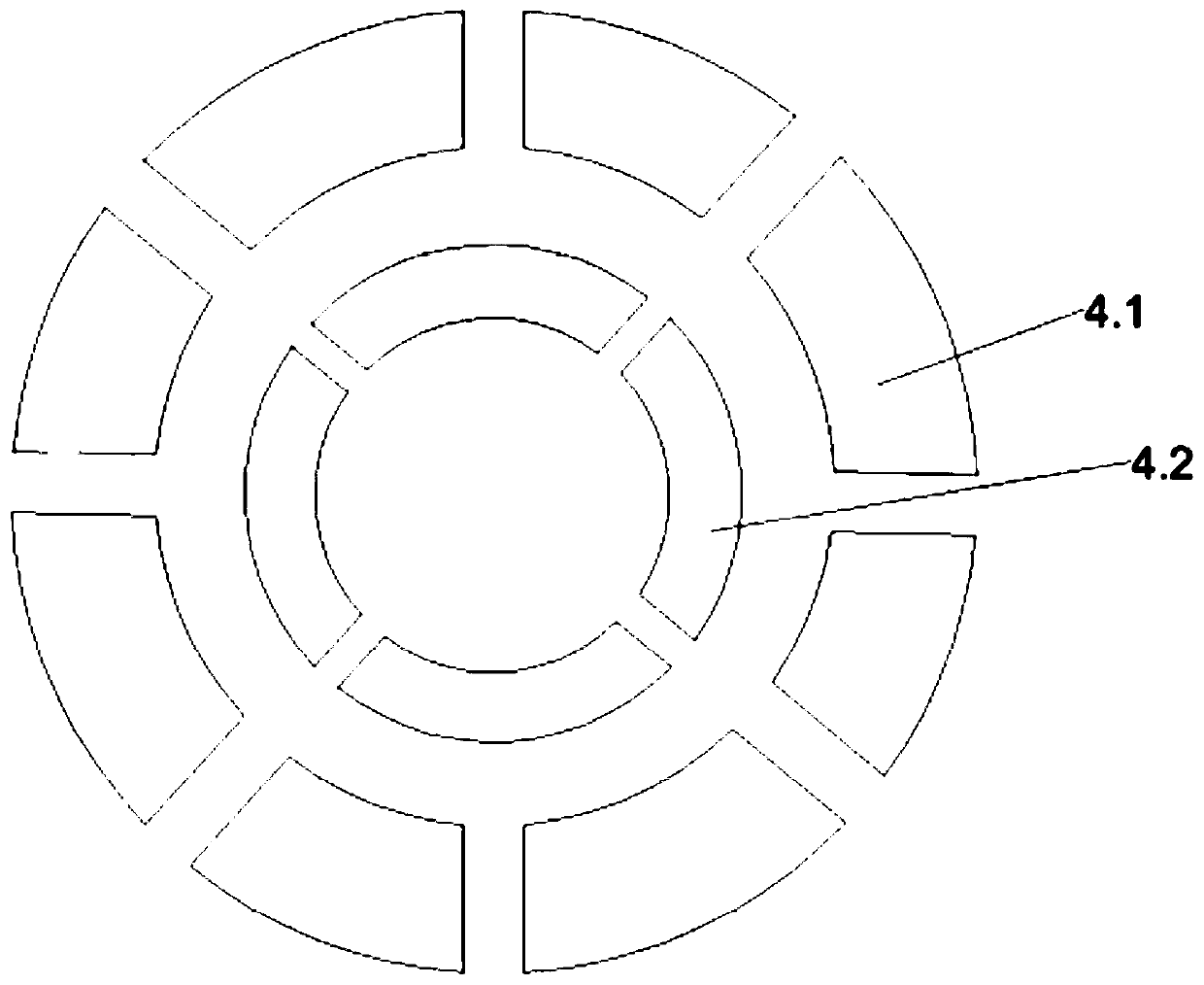

[0035]The stator device in this embodiment includes a shell and a disk-shaped non-magnetically conductive bracket 3 fixed on the inside of the shell. The shell includes an upper shell 5.1 and a lower shell 5.2 that are fixedly connected to each other through a sixth bolt 6.6. There is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com