Condensation type module boiler exhaust structure and method

A modular furnace, condensing technology, applied in chemical instruments and methods, combustion methods, exhaust gas devices, etc., can solve problems such as corrosion of pipelines and pipeline damage, and achieve the effect of avoiding corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

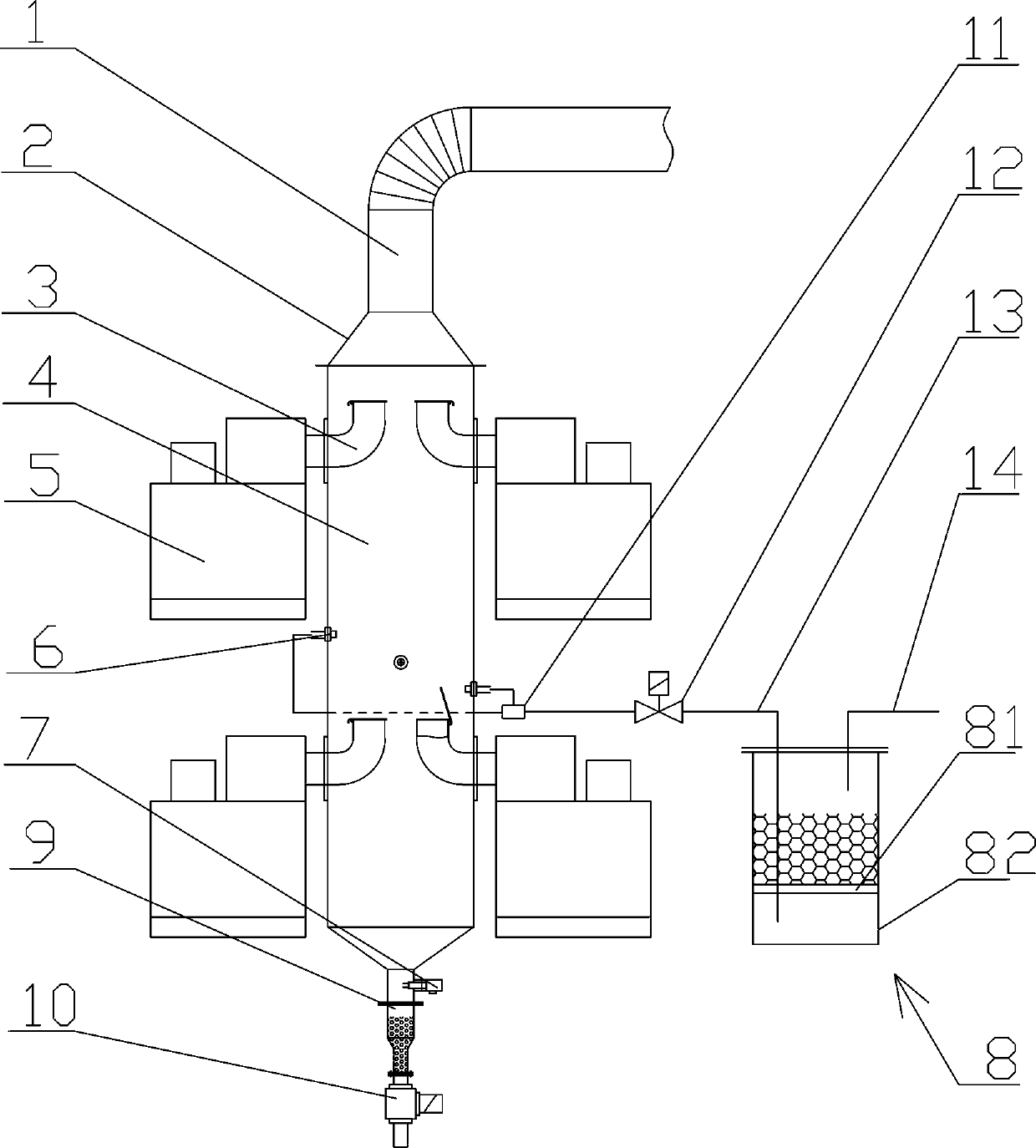

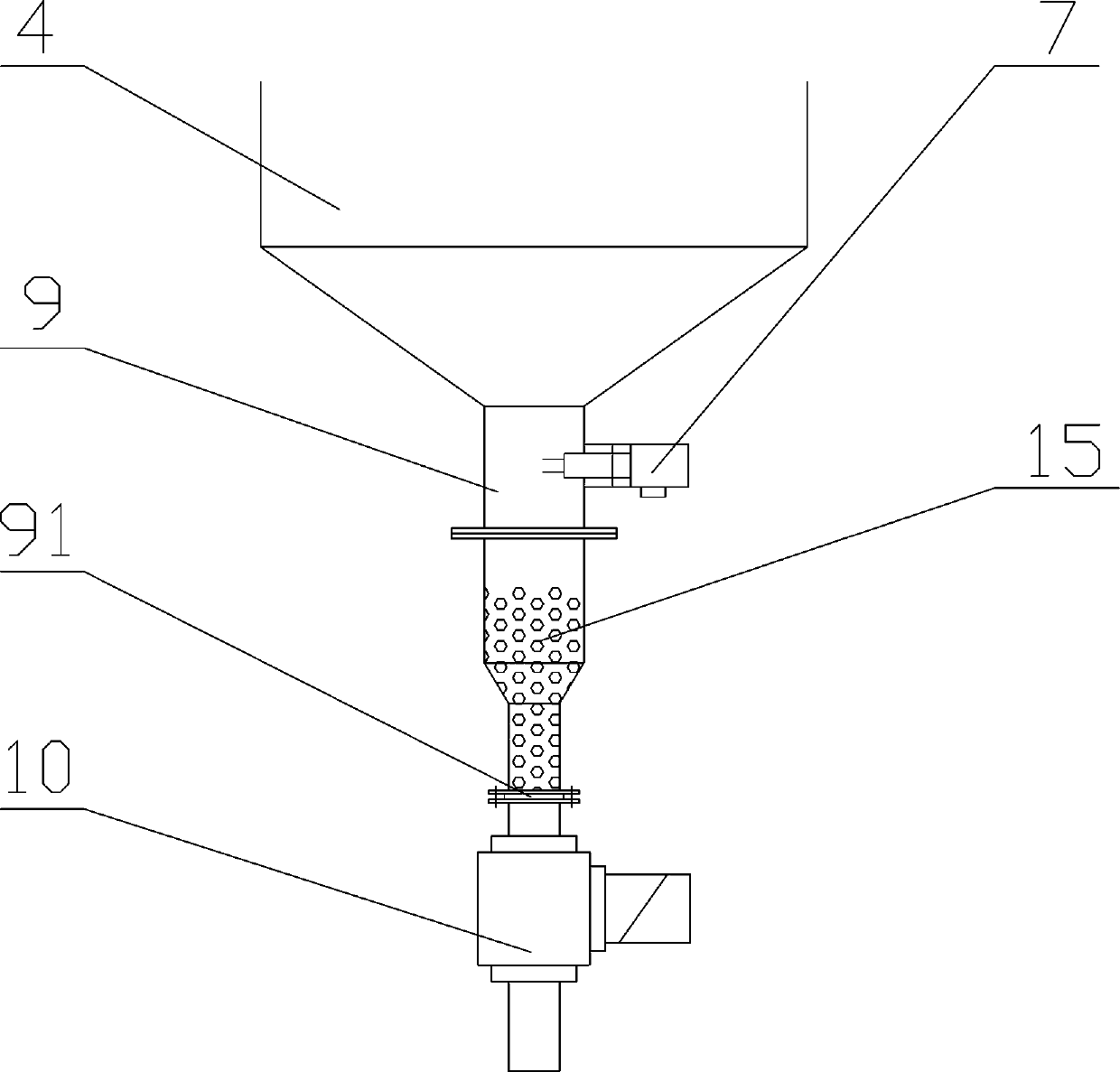

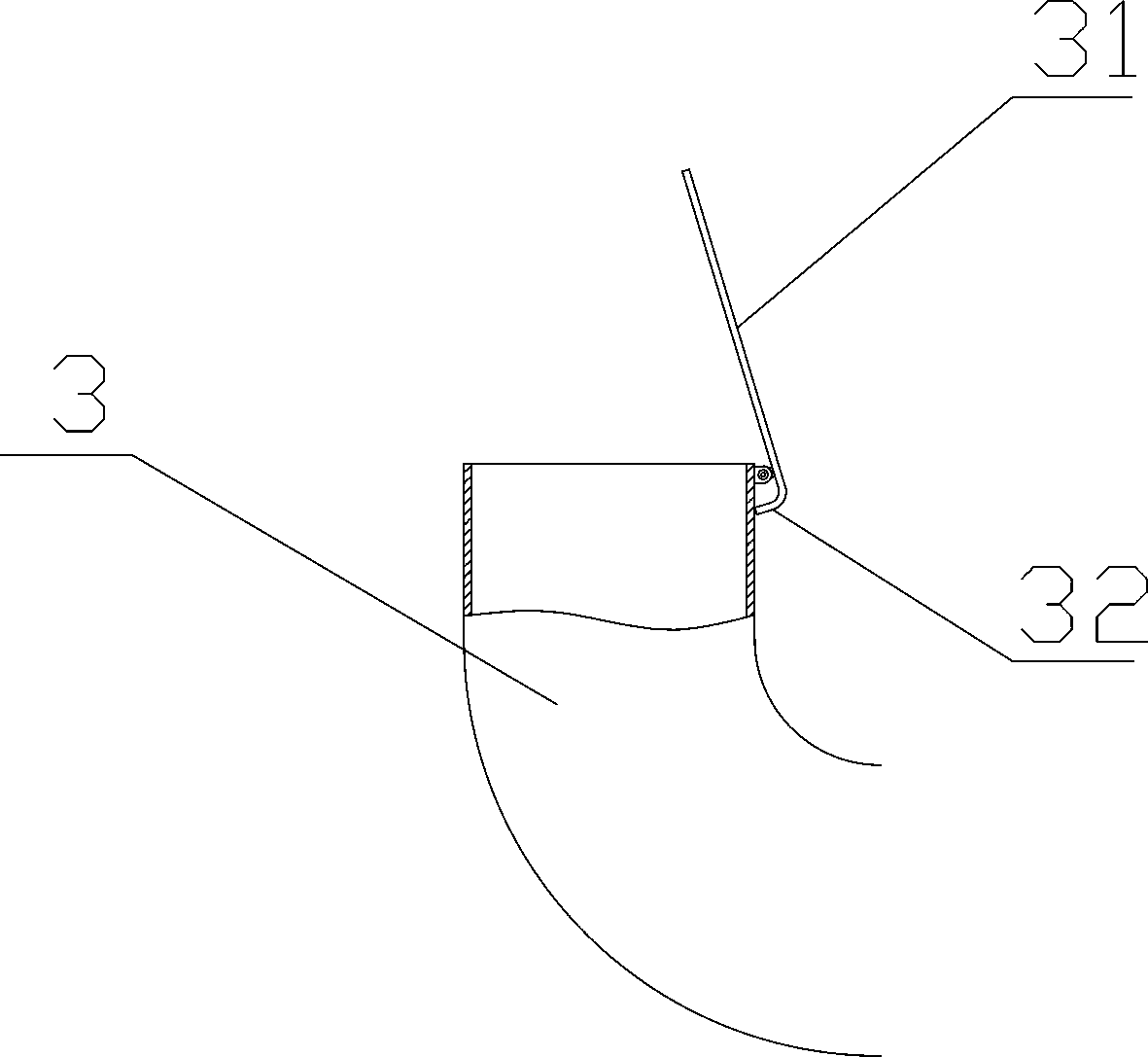

[0018] like Figures 1 to 4 As shown, a condensing modular furnace exhaust structure includes a smoke collection pipe 4, the upper end of the smoke collection pipe 4 is connected to the smoke exhaust pipe 1 through a tapered pipe 2, and the smoke exhaust pipe 1 is connected to each modular furnace through a plurality of curved pipes 3 5. The exhaust port is connected, and the mouths of the 3 pipes of each elbow are facing upwards. Covers 31 are covered on the mouths of the 3 pipes. One end of the cover 31 is hinged with the mouths of the 3 pipes. The cover is connected to the drain pipe 9, the first solenoid valve 10 is installed on the drain pipe 9, and a plurality of atomizing nozzles 6 are installed on the smoke collecting pipe 4, and the water inlet pipe 13 is connected to each atomizing nozzle 6 through the water separator 11 One end of the water inlet pipe 13 is connected to the tap water pipe 14, and the second solenoid valve 12 is installed on the water inlet pipe 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com