TBM rock breaking test bed with linear/rotary dual modes

A test bench and dual-mode technology, applied in the direction of testing machinability, measuring devices, instruments, etc., can solve the problems of unrealistic simulation of shield machines, unreasonable force, complex structure, etc., to achieve reasonable force and prolong service life The effect of life and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

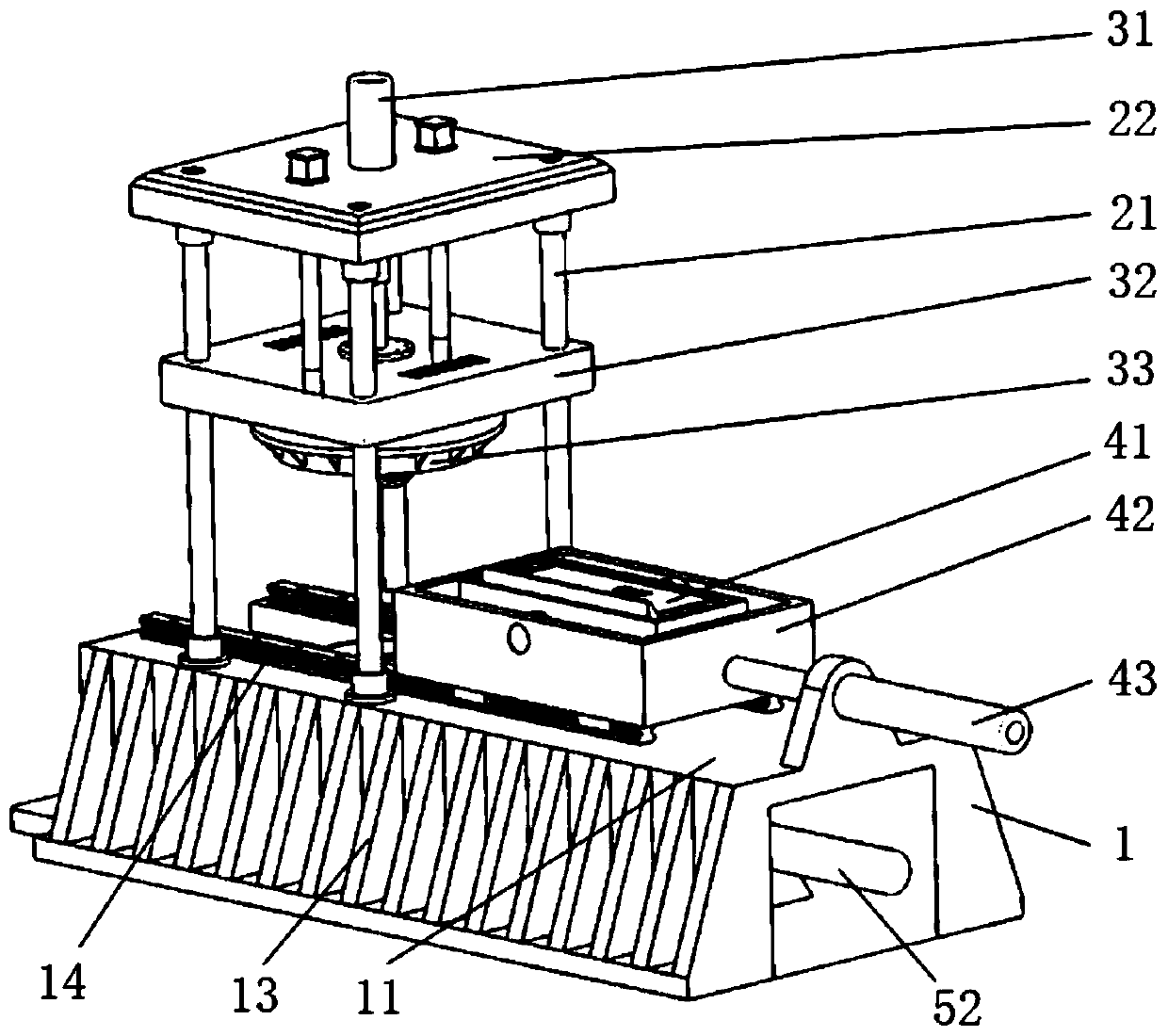

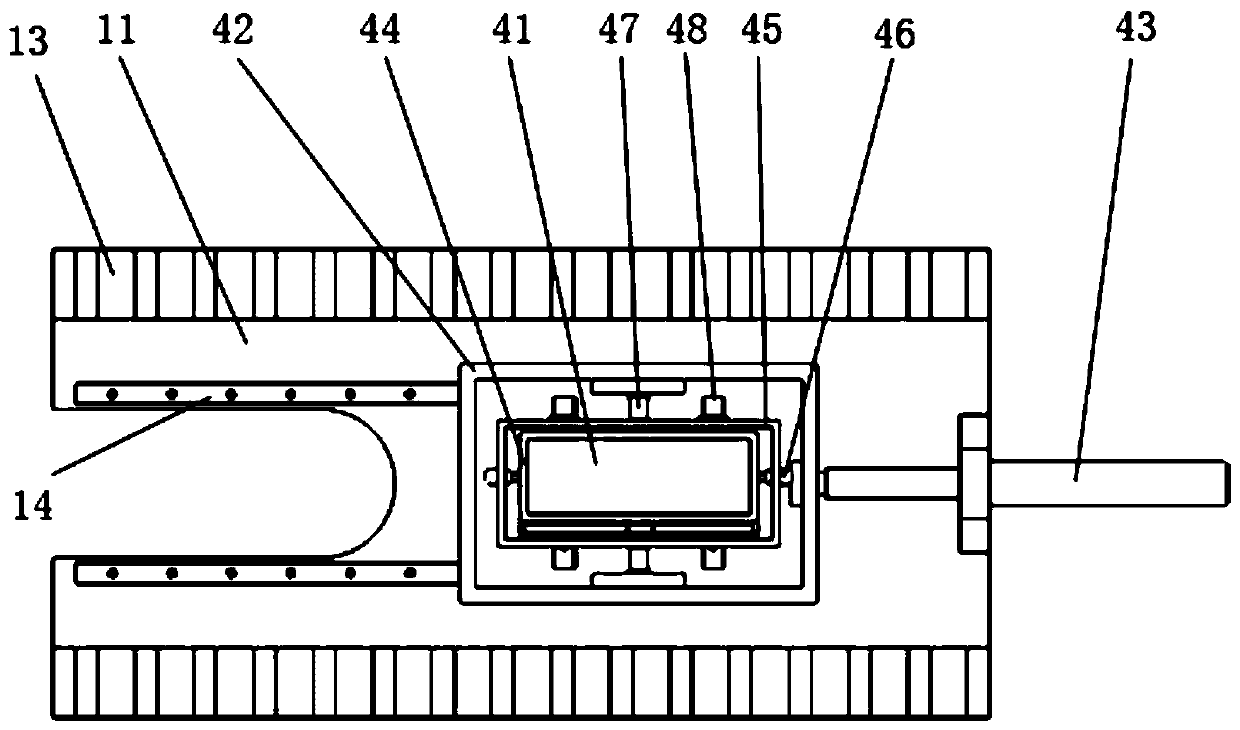

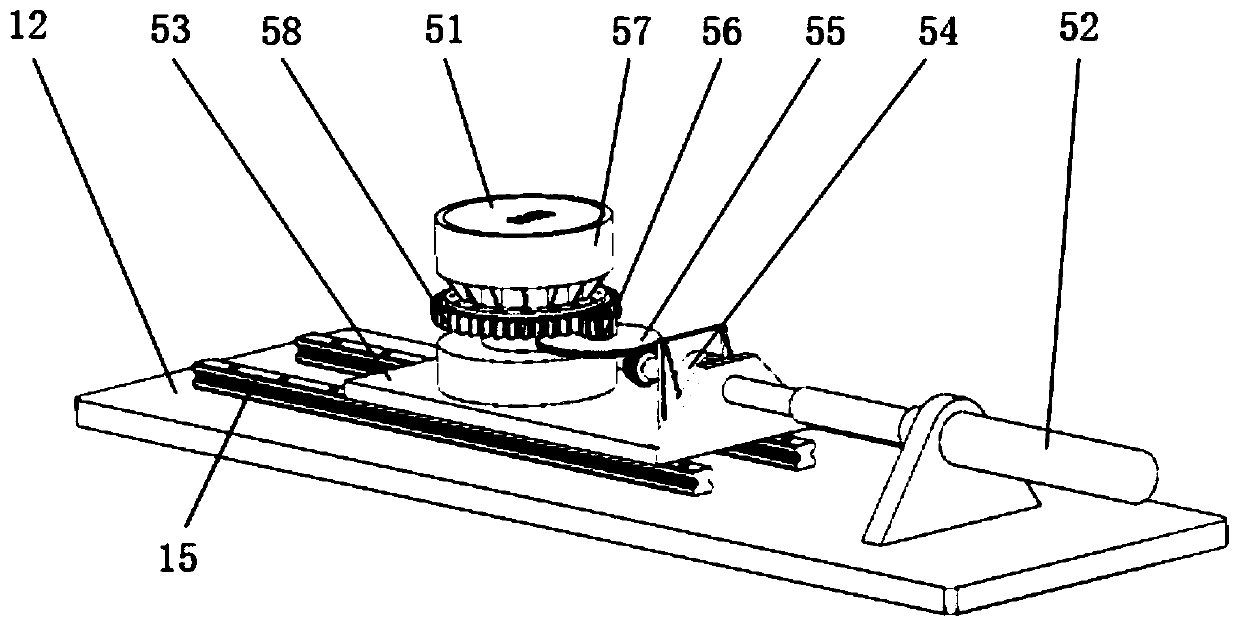

[0047] Combine below Figure 1 to Figure 5 The present invention will be described in detail.

[0048] A TBM rock-breaking test bench with linear / rotary dual modes, comprising a base 1 and a mounting frame, the bottom of the mounting frame is bolted to the base 1, and a loading device is installed on the mounting frame. The base 1 adopts a double-layer structure, including an upper test stand 11 and a lower test stand 12. One side of the upper test stand 11 is provided with a first horizontal hydraulic cylinder 43 and a first track 14, and the first track 14 is provided with a A linear soil box device, the linear soil box device is connected with the first horizontal hydraulic cylinder 43 . The lower test bench 12 is provided with a second horizontal hydraulic cylinder 52 and a second rail 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com