Circuit breaker flexible automatic assembly manufacturing process and matched production line thereof

A manufacturing process and automatic assembly technology, applied in the manufacture of emergency protection devices, circuits, emergency protection devices, etc., can solve problems such as rigid production, achieve the effects of improving flexibility, reducing input costs, and improving product manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

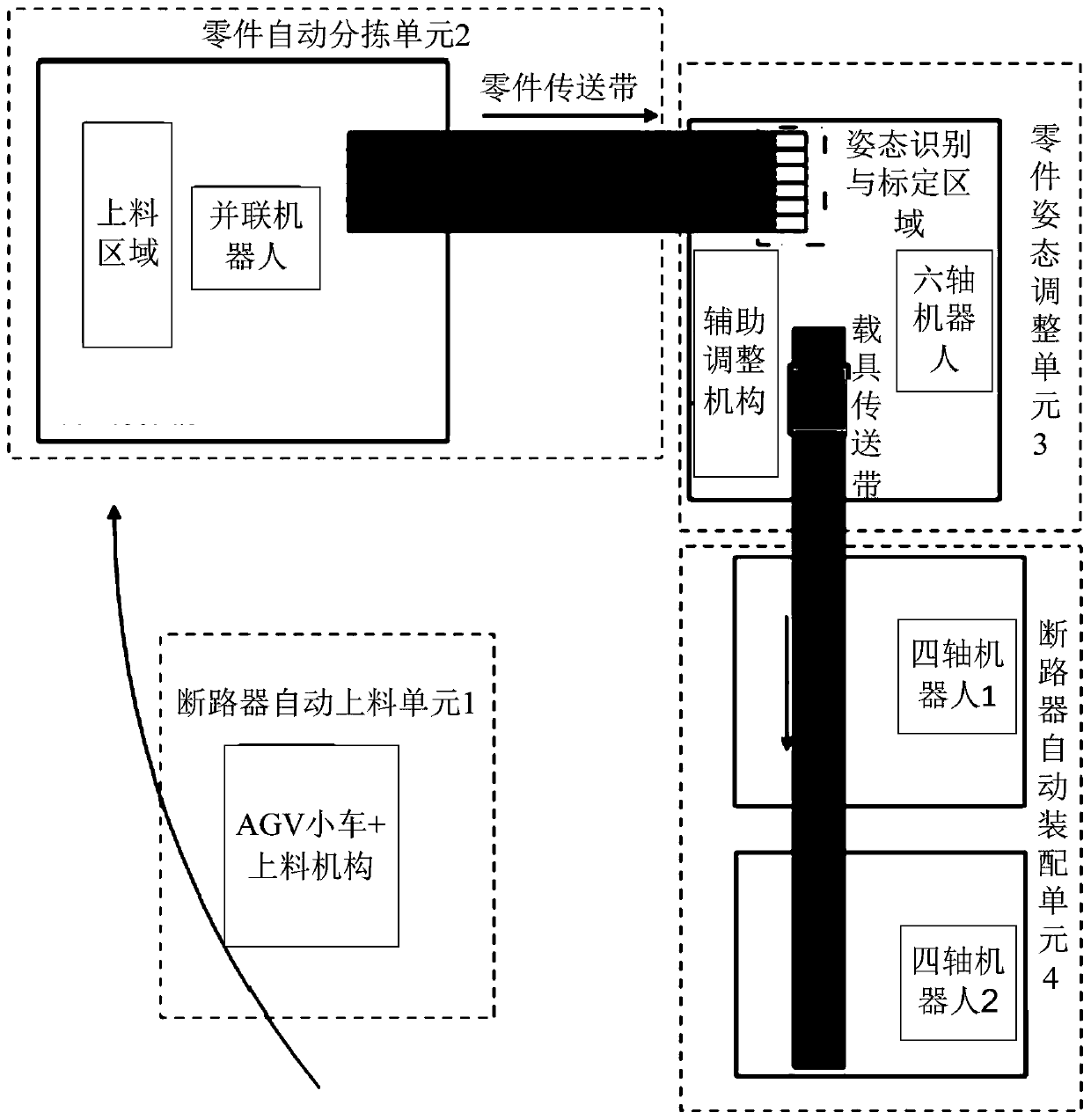

[0048] Such as figure 1 As shown, in the embodiment of the present invention, a circuit breaker flexible automatic assembly manufacturing process supporting production line is provided, including circuit breaker automatic feeding unit 1, parts automatic sorting unit 2, parts attitude adjustment unit 3 and circuit breaker automatic assembly Unit 4; where,

[0049] Circuit breaker automatic feeding unit 1 includes a feeding mechanism and an AGV trolley;

[0050] Parts automatic sorting unit 2 includes a parallel robot and a loading area and a parts conveyor belt on its table;

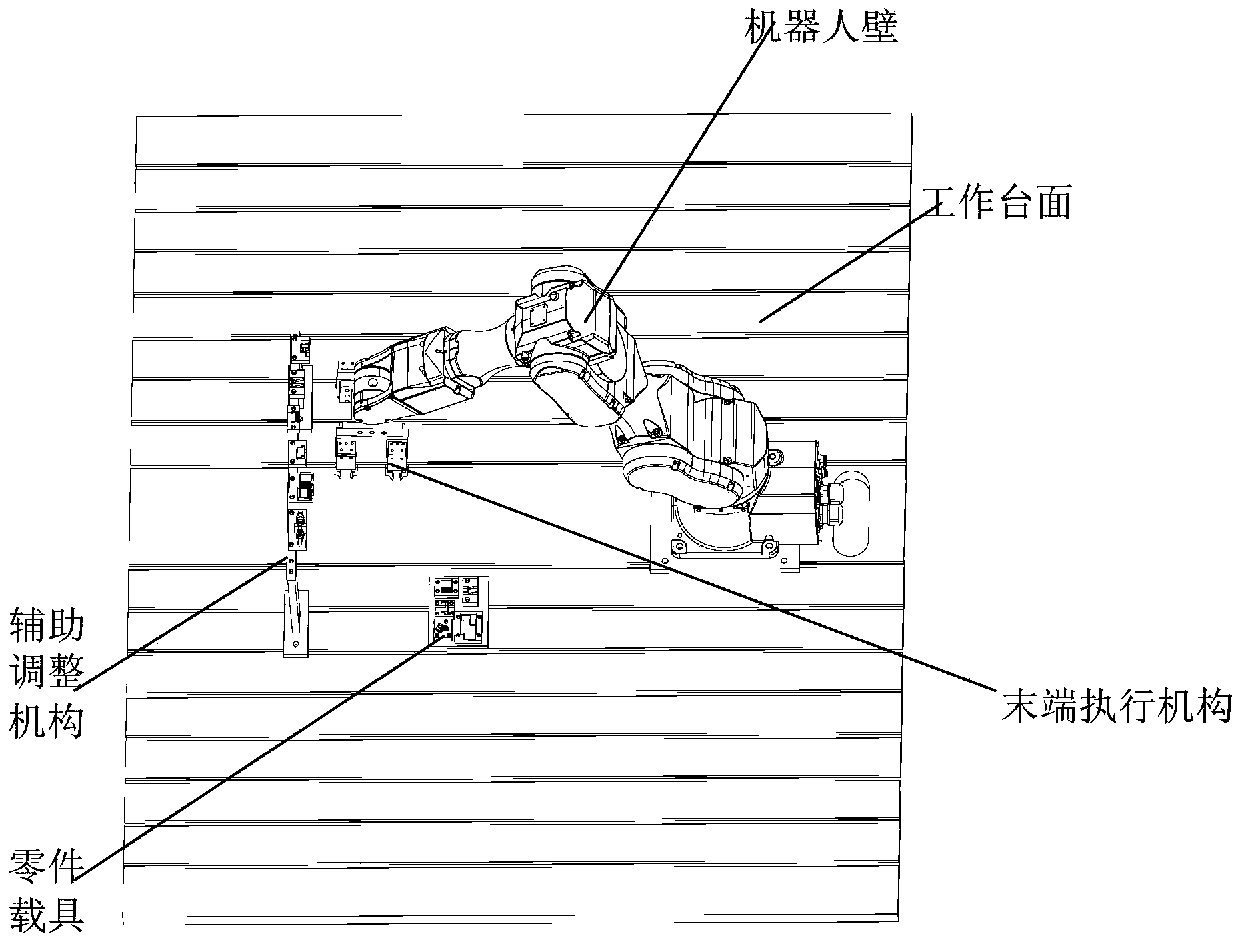

[0051] The part posture adjustment unit 3 includes a six-axis robot, an auxiliary adjustment mechanism, a posture recognition and calibration area on the table of the six-axis robot, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com