Perovskite light emitting diode

A light-emitting diode and perovskite technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems affecting light-emitting efficiency, light loss, etc., and achieve the effect of improving light-emitting efficiency, improving life and reliability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

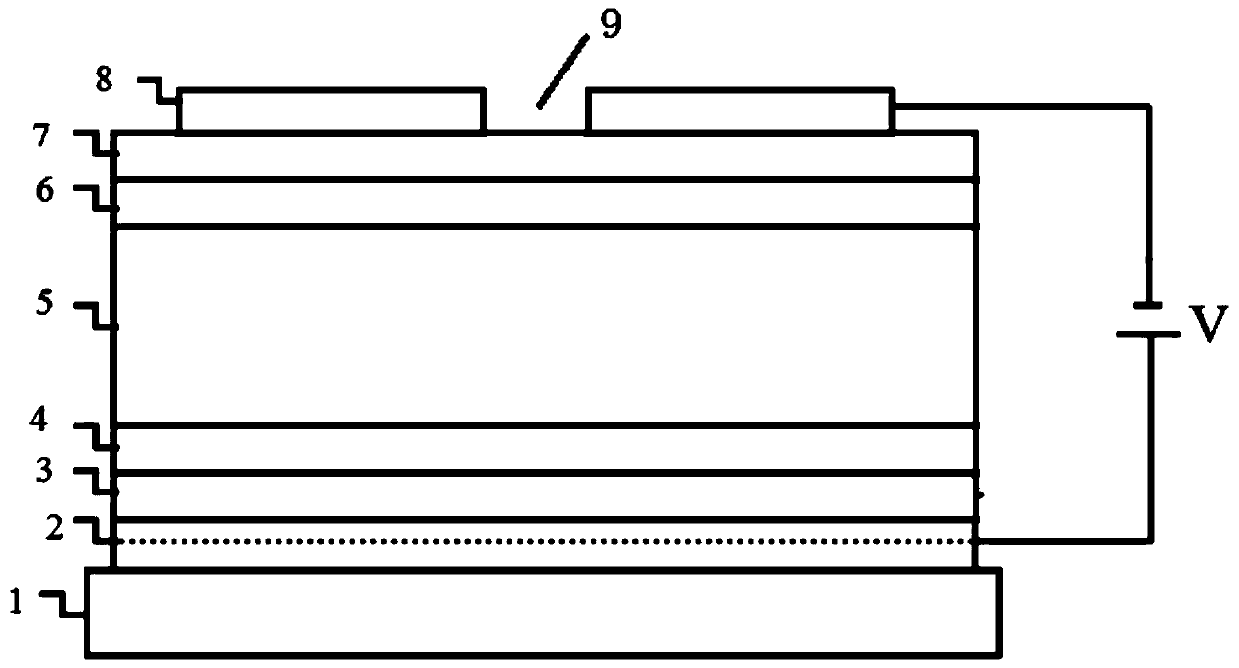

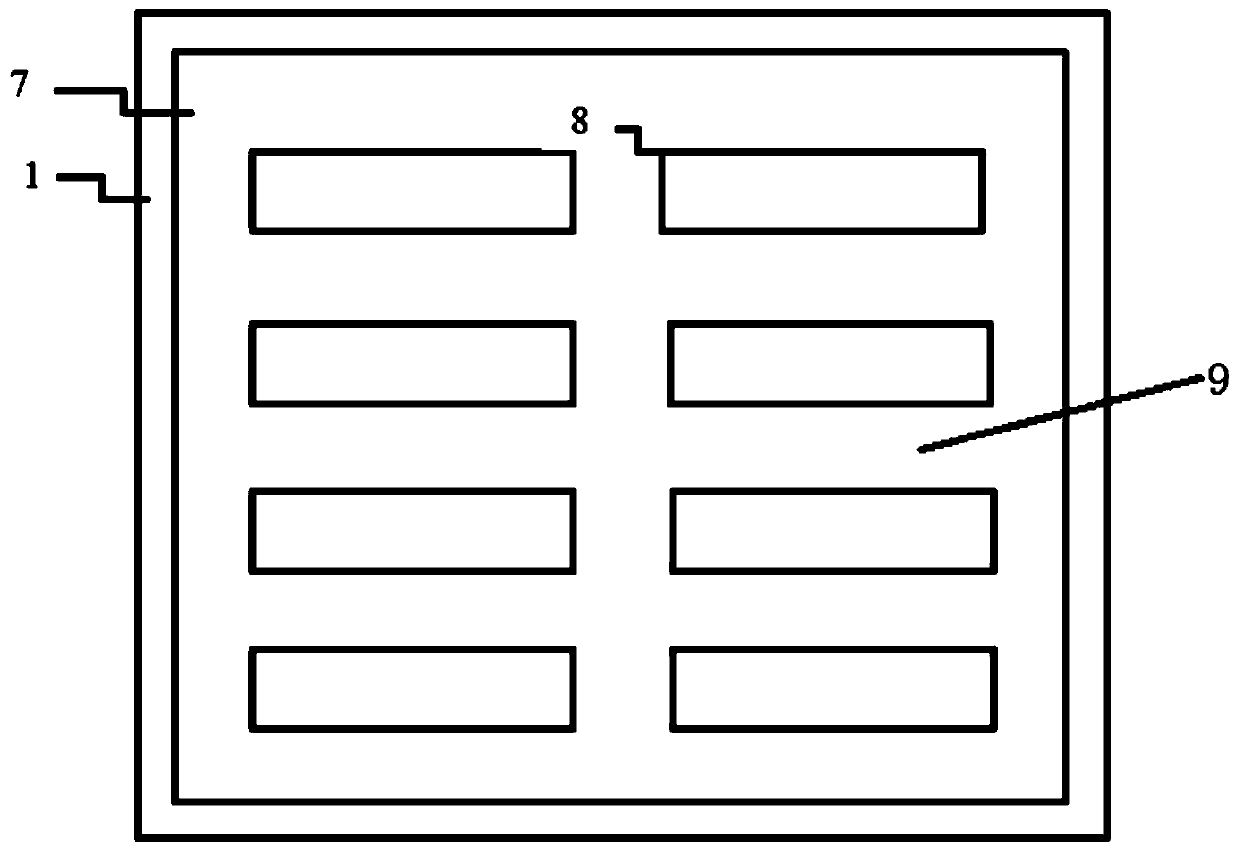

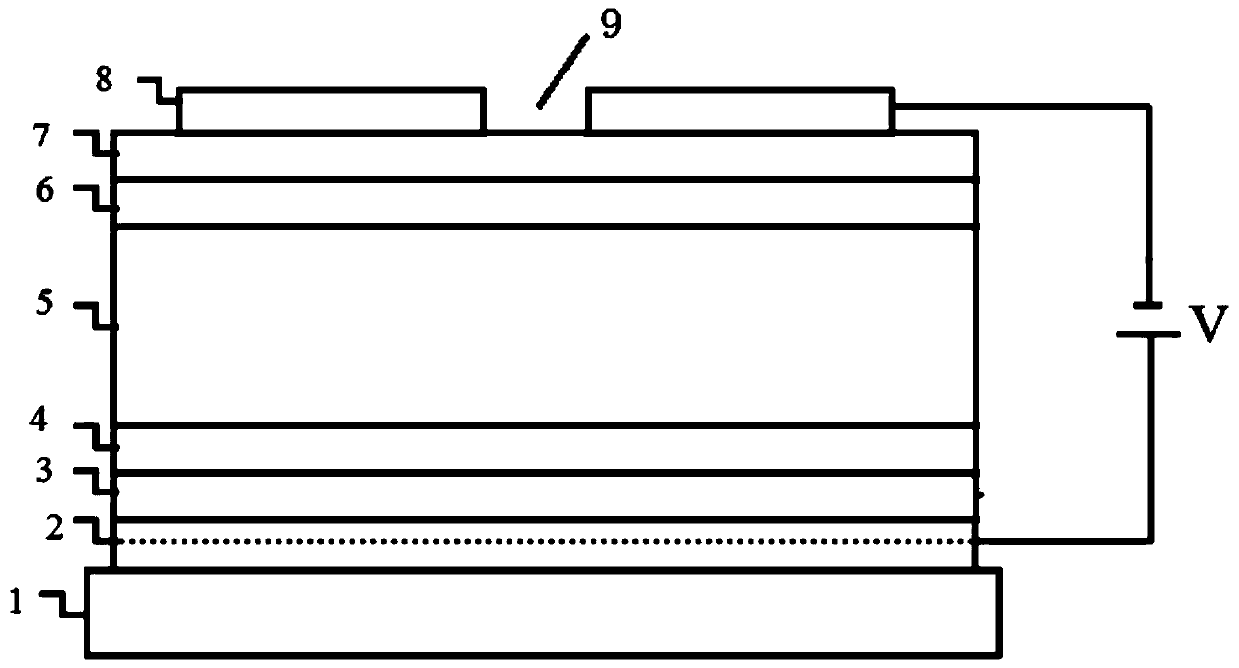

[0033] A perovskite light-emitting diode structure, from the bottom to the top structure is a substrate 1, a P-type electrode 2, a hole transport layer 3, a perovskite active light-emitting region 4, an electron transport layer 5, a mirror layer 6, The protective layer 7, the N-type electrode 8, the P-type electrode 2 is prepared on the substrate, the N-type electrode 8 is prepared on the protective layer, and an air channel 9 is left between a plurality of N-type electrodes 8; the P-type electrode 2 and the N-type The electrodes 8 are respectively connected to the positive pole and the negative pole of the external power supply.

[0034] In this embodiment, the substrate 1 is made of glass material; the thickness is 0.5 mm; the P-type electrode 2 is made of ITO material; prepared by spin coating; the thickness is 100 nm; the hole transport layer 3 is made of PEDOT:PSS; prepared by spin coating The thickness is 50nm; the perovskite active light-emitting region 4 is made of per...

Embodiment 2

[0036] A perovskite light-emitting diode structure, from the bottom to the top structure is a substrate 1, a P-type electrode 2, a hole transport layer 3, a perovskite active light-emitting region 4, an electron transport layer 5, a mirror layer 6, The protective layer 7, the N-type electrode 8, the P-type electrode 2 is prepared on the substrate, the N-type electrode 8 is prepared on the protective layer, and an air channel 9 is left between a plurality of N-type electrodes 8; the P-type electrode 2 and the N-type The electrodes 8 are respectively connected to the positive pole and the negative pole of the external power supply.

[0037] In this embodiment, the substrate 1 is made of glass material; the thickness is 1 mm; the P-type electrode 2 is made of ITO material; it is prepared by spin coating; the thickness is 150 nm; the hole transport layer 3 is made of TFB; it is prepared by spin coating; 100nm; the perovskite active light-emitting region 4 is made of two-dimensiona...

Embodiment 3

[0039] A perovskite light-emitting diode structure, from the bottom to the top structure is a substrate 1, a P-type electrode 2, a hole transport layer 3, a perovskite active light-emitting region 4, an electron transport layer 5, a mirror layer 6, The protective layer 7, the N-type electrode 8, the P-type electrode 2 is prepared on the substrate, the N-type electrode 8 is prepared on the protective layer, and an air channel 9 is left between a plurality of N-type electrodes 8; the P-type electrode 2 and the N-type The electrodes 8 are respectively connected to the positive pole and the negative pole of the external power supply.

[0040] In this embodiment, the substrate 1 is made of glass material; the thickness is 0.75 mm; the P-type electrode 2 is made of ITO material; it is prepared by spin coating; the thickness is 150 nm; the hole transport layer 3 is PVK; it is prepared by spin coating; 75nm; the perovskite active light-emitting region 4 is made of three-dimensional pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com