Mute motor structure convenient to install

A motor structure and quiet technology, which is applied in the field of micro motors, can solve the problems of reducing structural stability, difficult installation, and affecting the normal operation of the connection stability of internal parts of micro motors, etc., to achieve stable working positions and convenient and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

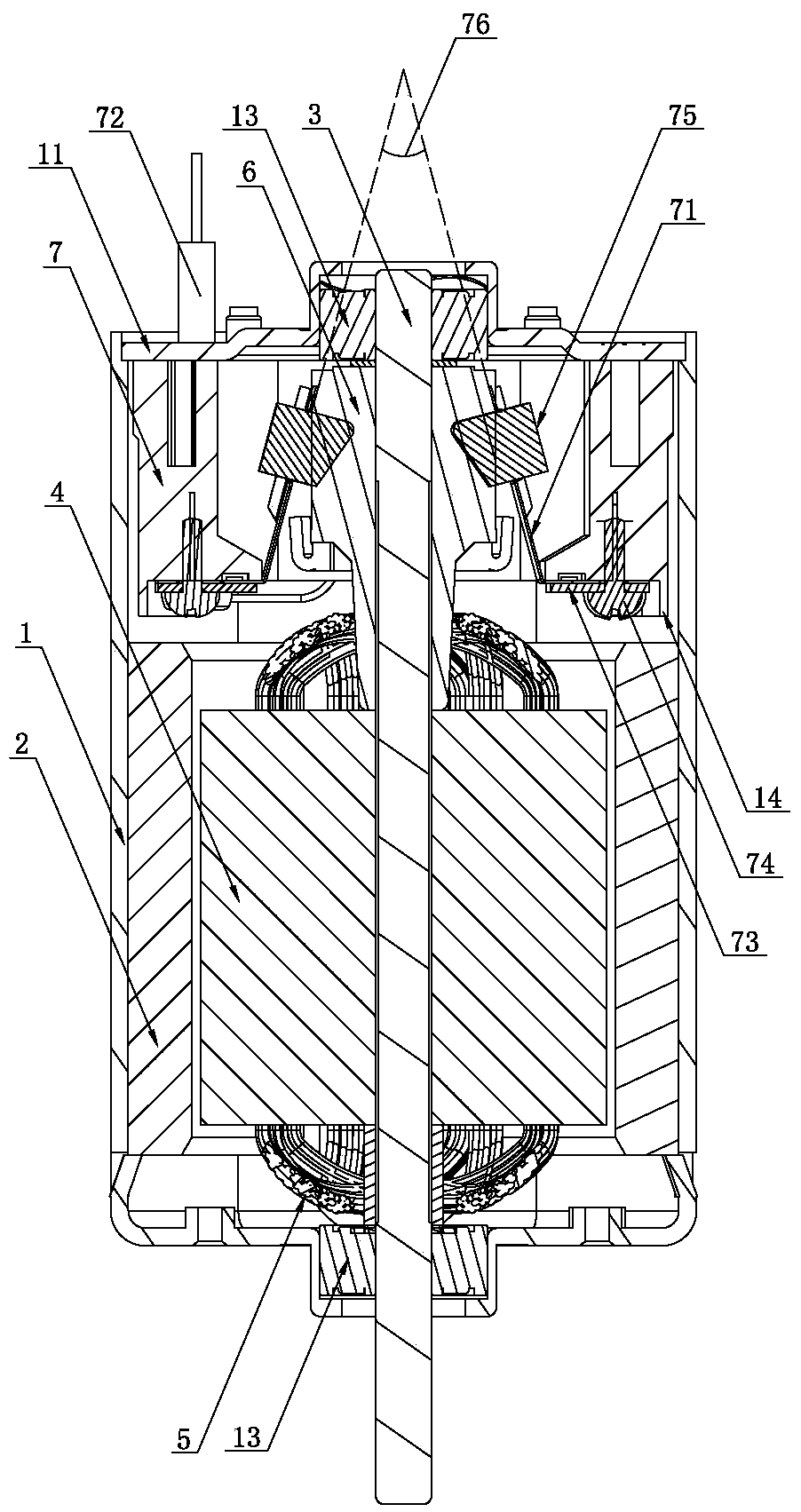

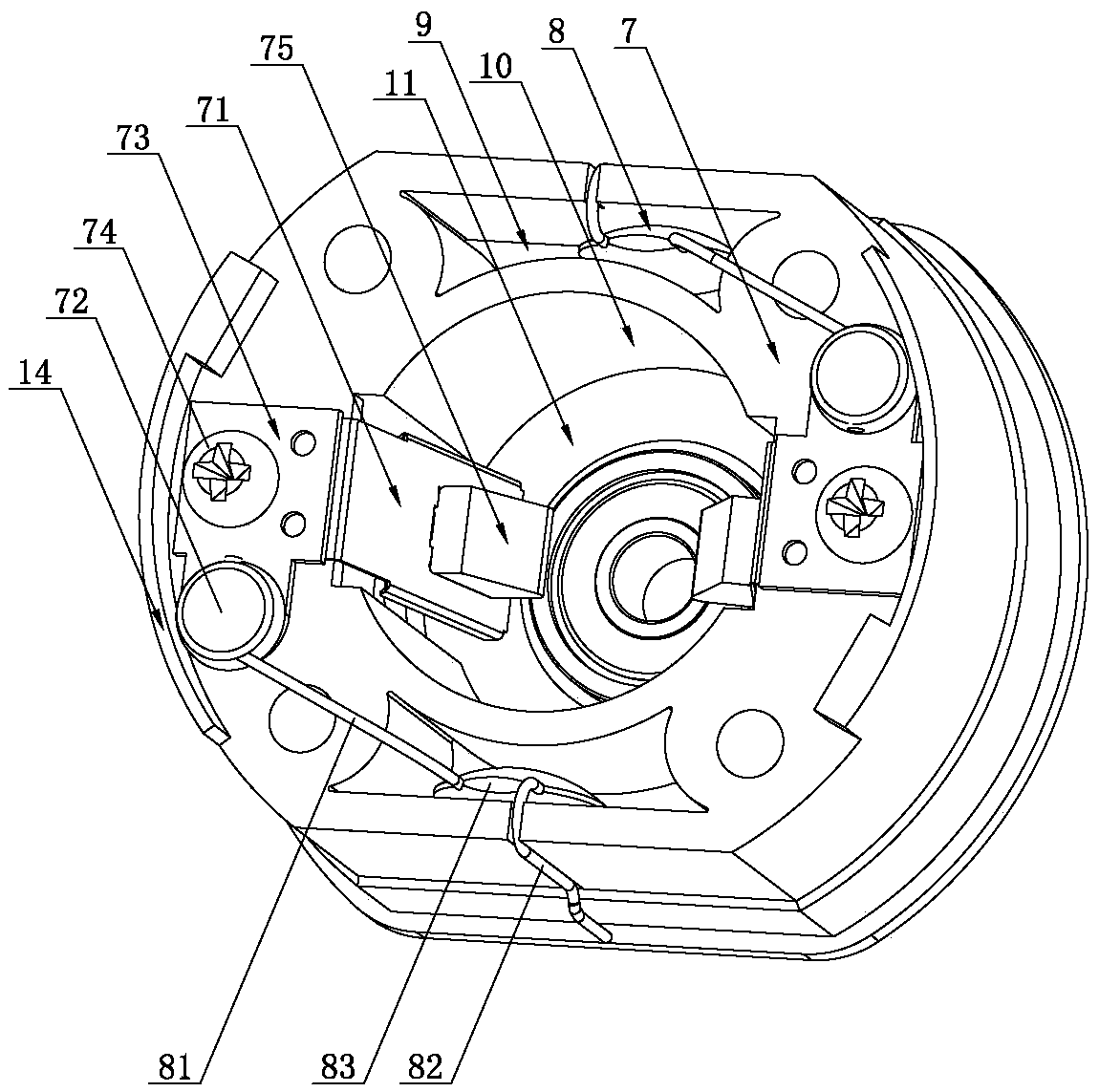

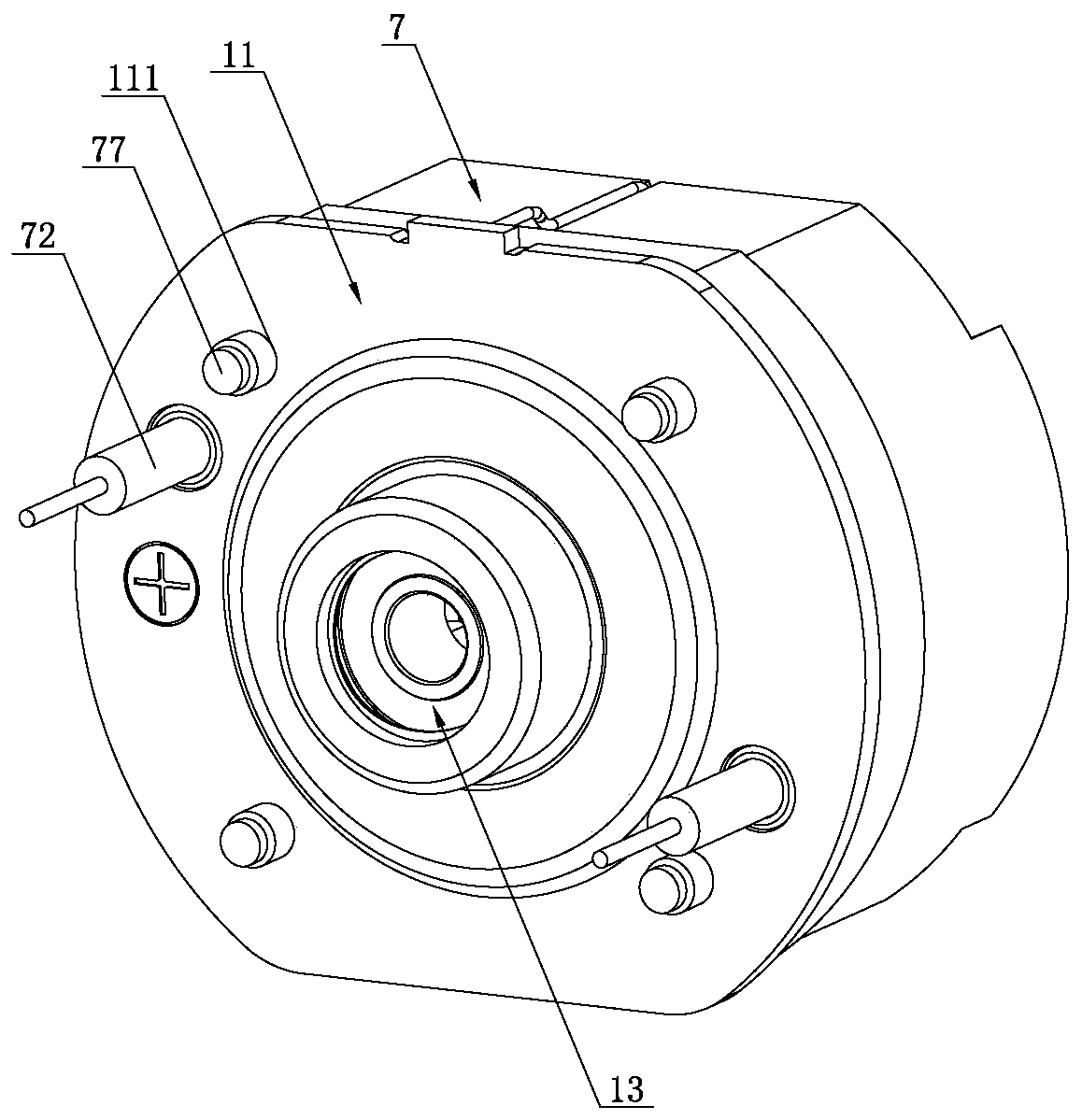

[0039] Such as Figure 1 to Figure 6 As shown, an easy-to-install silent motor structure of the present invention includes a motor housing 1, a magnetic tile 2 is disposed inside the motor housing 1, and a motor shaft 3 is disposed in the middle of the motor housing 1. , the motor shaft 3 is provided with a rotor 4, the rotor 4 is wound with an armature winding 5, the rotor 4 is connected with a commutator 6, and one end of the motor housing 1 is provided with an end cover 7, so Both sides of the end cover 7 are provided with a carbon brush arm 71 and an electrical terminal 72, and the top of the carbon brush arm 71 is provided with a conductive terminal 73, and a screw is connected between the conductive terminal 73 and the carbon brush arm 71. 74, one end of the carbon brush arm 71 is suspended and a carbon brush 75 is provided, and an installation guide angle 76 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com