Heat exchange system for ultrahigh-pressure refrigeration equipment and ultrahigh-pressure refrigeration equipment

A technology of heat exchange system and refrigeration equipment, applied in the field of heat exchange system and ultra-high pressure refrigeration equipment, can solve the problems of wasting energy, long refrigeration time, low heat exchange efficiency, etc., to improve heat exchange efficiency, uniform temperature and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

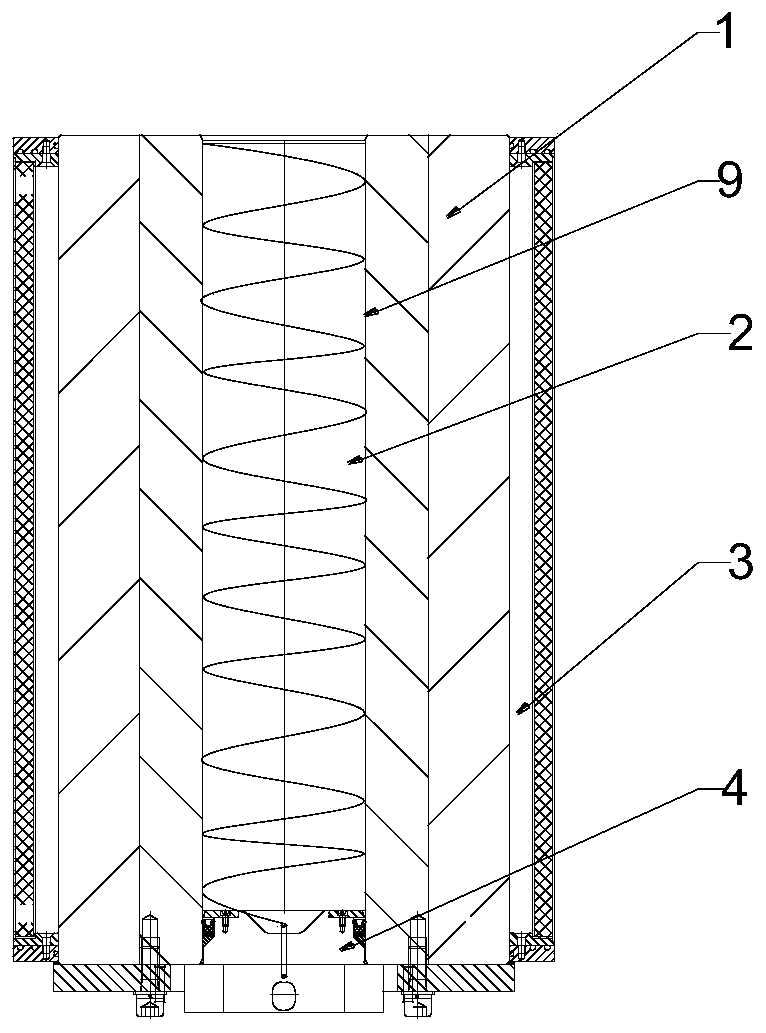

[0034] like Figure 2-Figure 3 As shown, the present invention is used for the heat exchange system of the ultra-high pressure refrigerating equipment, including the outer heat exchange assembly 3 arranged outside the high pressure refrigerating chamber 9 of the ultra-high pressure refrigerating equipment and the inner heat exchange assembly 2 arranged in the high pressure refrigerating chamber 9, The inner heat exchange assembly 2 is spirally arranged on the inner wall of the high-pressure freezing chamber 9, and the refrigerant inlet and the refrigerant outlet of the inner heat exchange assembly 2 are both arranged on the bottom plug 4 at the bottom of the high-pressure freezing chamber 9, and the built-in The refrigerant inlet and refrigerant outlet of the heat exchange assembly 2 are connected to the external water pump through the bottom block 4 for forced circulation, which can directly cool the medium in the high-pressure freezing chamber 9, and establish a medium in the...

Embodiment 2

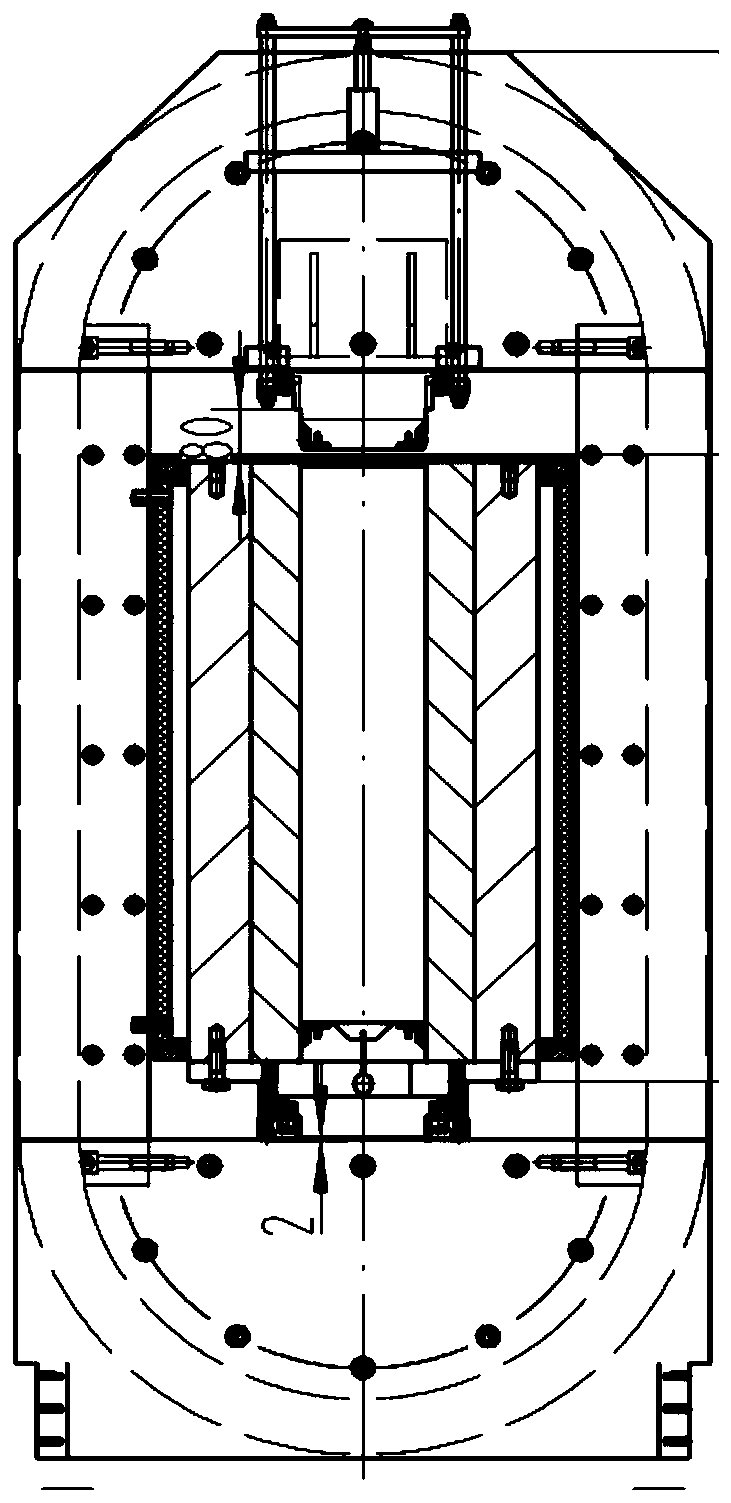

[0040] like Figure 4 As shown, the ultra-high pressure refrigeration equipment of the present invention comprises the heat exchange system described in Example 1, the ultra-high pressure reactor 6 and the supercharger 5 for pressurizing the ultra-high pressure reactor 6;

[0041] The ultra-high pressure reactor 6 is provided with an ultra-high pressure vessel 1, and a high-pressure freezing chamber 9 is formed in the ultra-high pressure vessel 1 for holding materials, and the outer heat exchange component 3 is sleeved in the ultra-high pressure vessel 1. Outside, the internal heat exchange assembly 2 is arranged in the high-pressure freezing chamber 9 of the ultra-high pressure vessel 1, and the bottom of the ultra-high pressure vessel 1 is provided with a mounting frame 7 for fixing in the ultra-high pressure reactor 6.

[0042] Further, the bottom of the ultra-high pressure reactor 6 is provided with a support plate 8 for fixing.

Embodiment 3

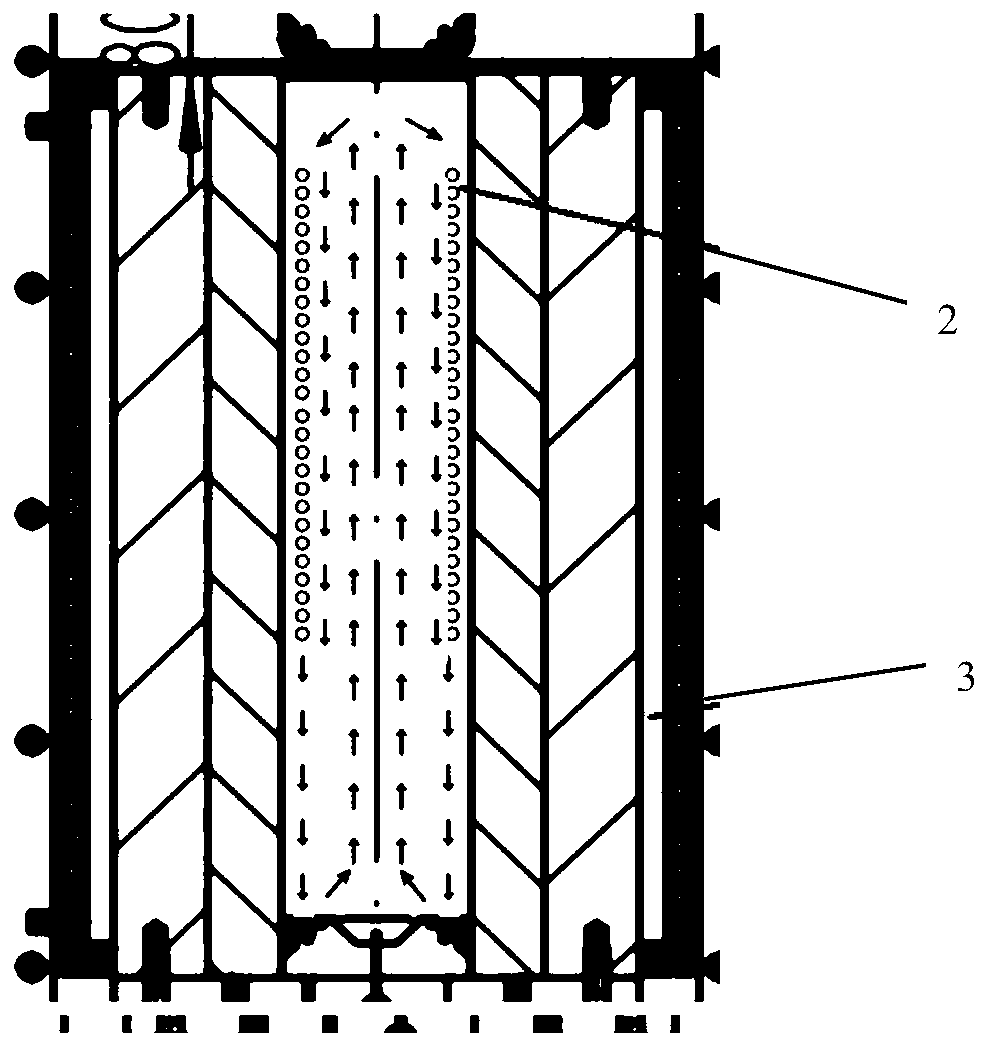

[0044] On the basis of Example 2, as Figure 5 As shown, a detachable barrel-shaped material basket 10 is installed in the high-pressure freezing chamber 9 of the ultra-high pressure refrigeration equipment, and a guide tube 11 is arranged in the middle of the material basket 10 to make the upper part of the material basket 10 temperature. The lower medium flows down along the basket wall of the material basket 10, and the higher temperature medium at the lower part of the material basket 10 can flow upward from the guide pipe 11 in the middle of the material basket 10 to form a circulating flow, which effectively improves the high-pressure freezing chamber 9. heat conduction effect.

[0045]Further, hooks extending outward are formed on the top of the basket 10, so that the basket 10 is clamped with the high-pressure freezing chamber 9, and it is convenient to remove the frozen products from the material after the ultra-high-pressure freezing process is completed. out of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com