Construction waste sorting system

A construction waste and sorting system technology, which is applied in construction waste recycling, solid separation, and separation of solids from solids by airflow, can solve the problems of time-consuming and labor-intensive, waste of resources, waste of resources, etc., and reduce transportation. The effect of equipment and conveying times, reducing dust pollution and noise pollution, energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

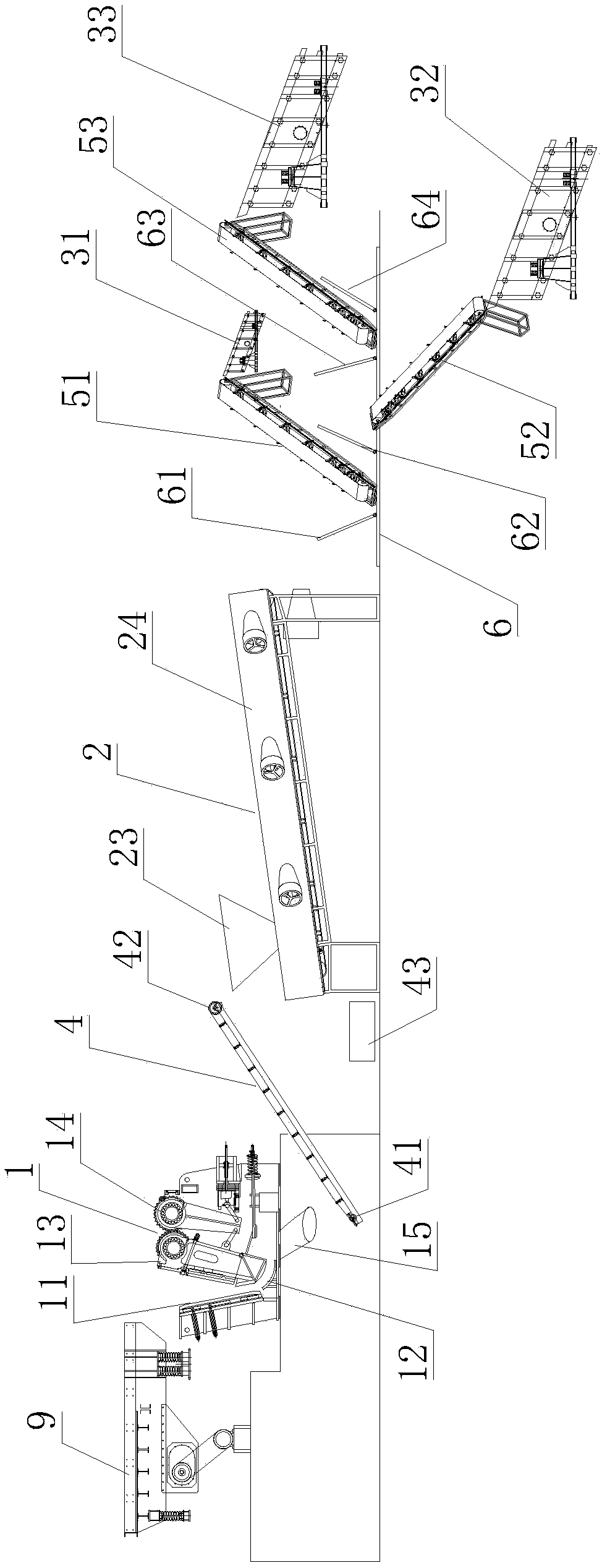

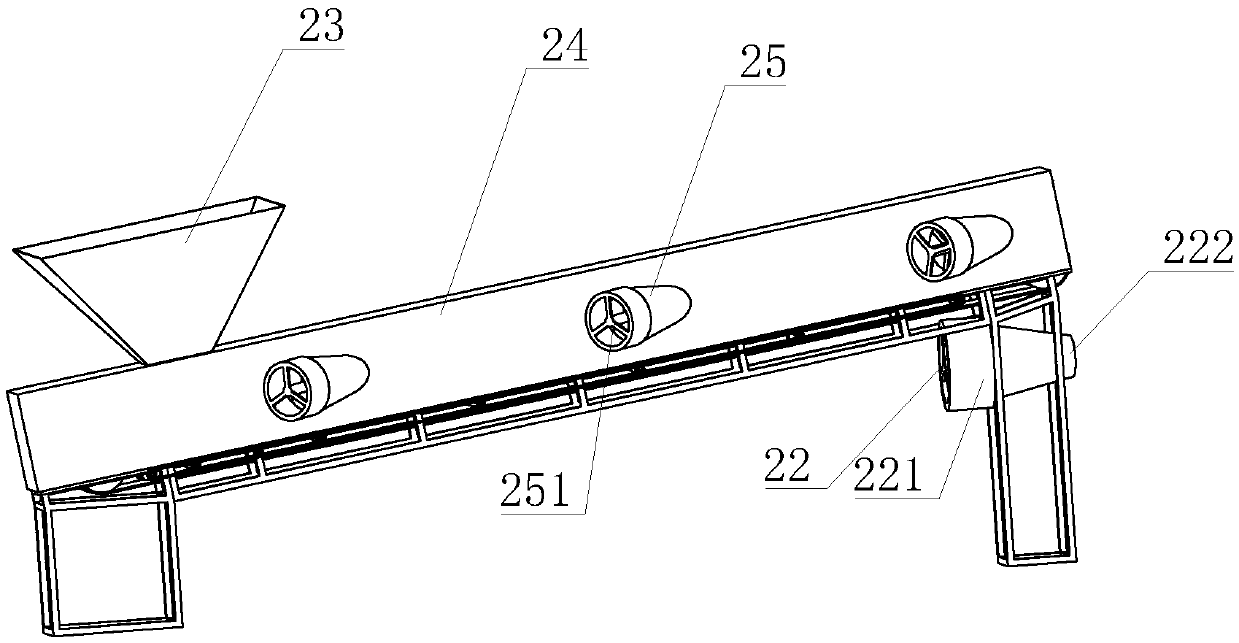

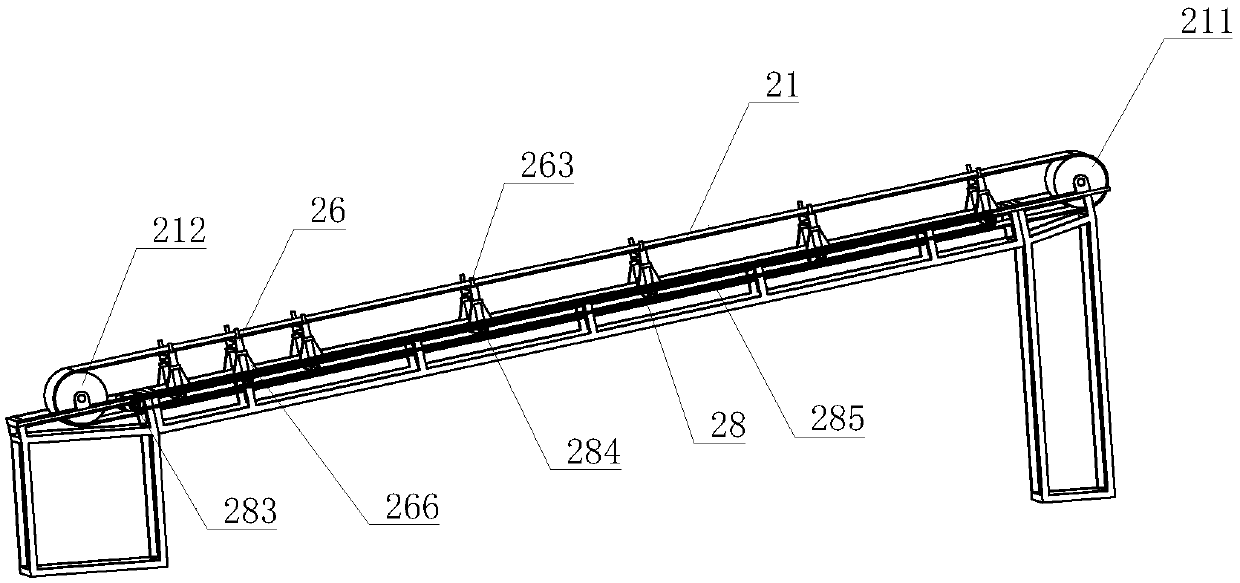

[0035] Embodiment one, see Figure 1-6 , this embodiment discloses a sorting system for construction waste, including crushing equipment, winnowing equipment 2, and screening equipment, which are connected by conveying equipment. The crushing equipment in this embodiment is a multi-stage crushing jaw crusher 1, and the screening equipment The sub-equipment is a vibrating screen, and the conveying equipment is a belt conveyor. From left to right, multi-stage crushing jaw crusher 1, magnetic separation conveyor 4, winnowing equipment 2, belt conveyor, vibrating screen, and multi-stage crushing are installed in sequence. The discharge port of the jaw crusher 1 extends to the top of the feed end of the magnetic separation conveyor 4 through the guide hopper 15, and the discharge end of the magnetic separation conveyor 4 is located above the feed bin 23 of the winnowing equipment 2, and the winnowing equipment 2 The first belt conveyor 51, the second belt conveyor 52, and the third...

Embodiment 2

[0046] Embodiment two, see Figure 6-9The difference between this embodiment and Embodiment 1 is that the power mechanism of the air separation equipment 2 throwing mechanism is a hydraulic cylinder 29, and the piston rod 291 of the hydraulic cylinder 29 abuts against the lower end of the push rod 27, and the construction waste is transported In the middle, the hydraulic cylinder 29 works, the piston rod 291 of the hydraulic cylinder 29 acts on the ejector rod 27, and the ejector rod 27 drives the idler roller mounting frame 26 to move up and down, so that the idler roller 261 moves up and down and acts on the conveyor belt 21 to move the conveyor belt 21 The garbage is thrown up, and the piston rod 291 is telescopic, so that the push rod 27 rises or moves down to cause the conveyor belt 21 to vibrate, so as to realize the throwing. The fourth belt conveyor 54 is provided, and the feeding end of the fourth belt conveyor 54 is located below the discharge port of the second vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com