A kind of high CTI, low temperature ultra-tough flame retardant PC material and preparation method thereof

A low-temperature, super-tough technology, applied in the field of polymer materials, can solve problems such as insufficient insulation performance, and achieve the effect of improving low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

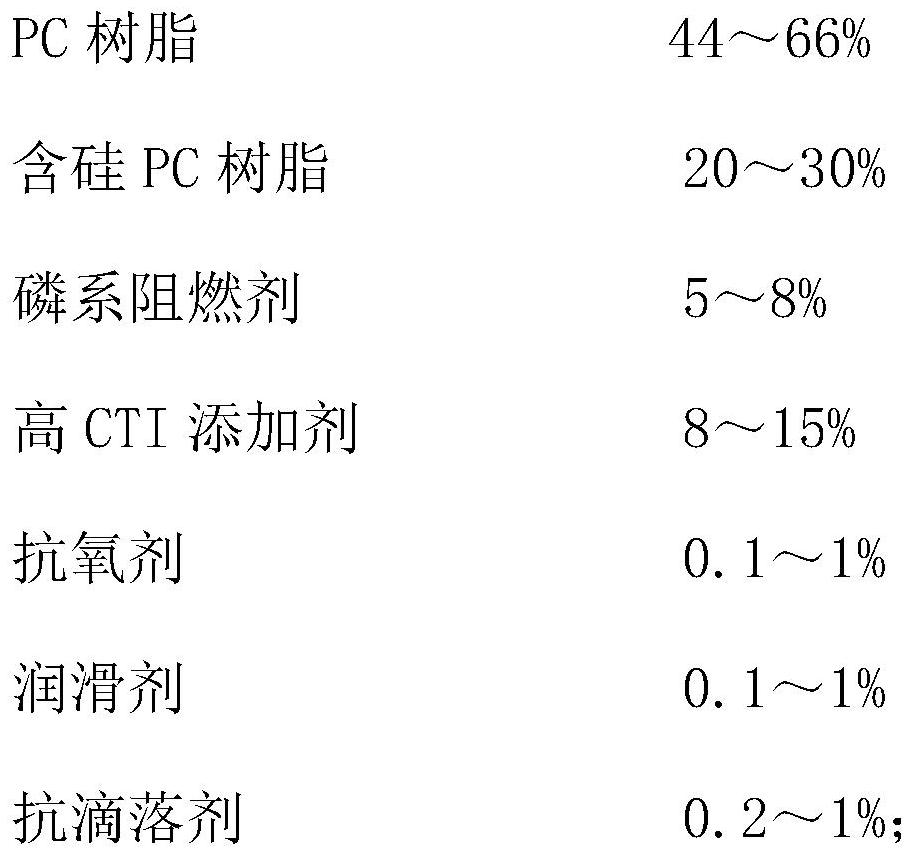

[0043] Described a kind of preparation method of high CTI, low temperature super tough flame retardant PC material, comprises the following steps:

[0044] A. Weigh PC resin, silicon-containing PC resin, phosphorus-based flame retardant, high CTI additive, antioxidant, lubricant and anti-dripping agent by weight percentage for use;

[0045] B, each component that is weighed in step A is mixed homogeneously;

[0046] C. After the mixture obtained in step B is extruded and granulated by twin screws, a high CTI, low temperature super tough flame retardant PC material is obtained.

[0047] By adding low molecular weight and medium particle size high insulating PTFE polymer as a high CTI additive in the system, the CTI of the material is improved, and phosphorus flame retardant is added to improve the flame retardant performance of the material, and high molecular weight PTFE is used as an anti-drip The agent can play the role of anti-drip and stable flame retardant, in addition, ...

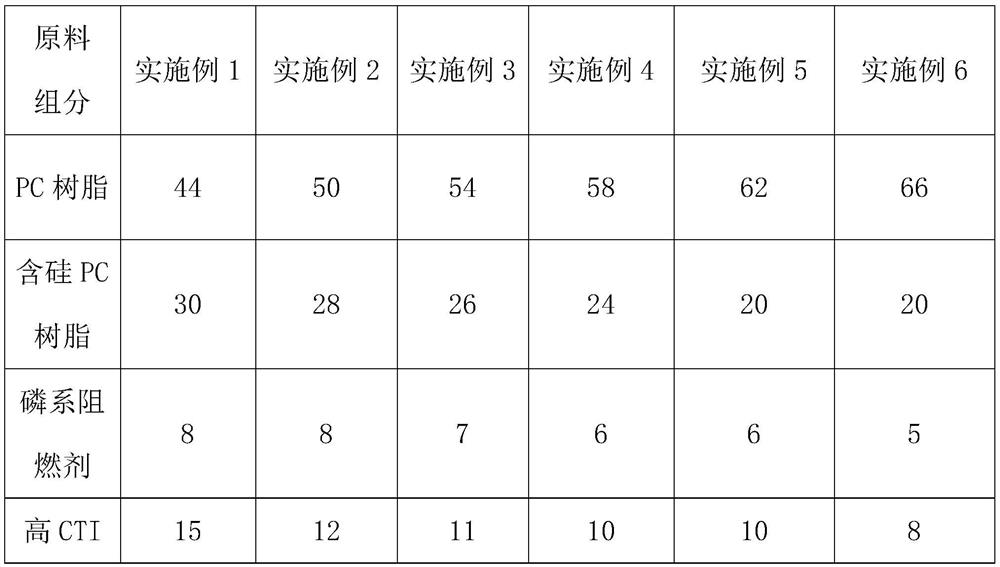

Embodiment 1-12 and comparative example 1-3

[0064] A high CTI, low temperature super tough flame retardant PC material is prepared according to the following steps:

[0065] (1) according to weight percent calculation, each raw material is taken by weighing the raw material component content of table 1 for subsequent use;

[0066] (2) each component weighed in step (1) is added in the mixing tank and mixed to obtain a mixture;

[0067] (3) adding the mixture obtained in the step (2) into a twin-screw extruder, and carrying out twin-screw extrusion granulation, the extrusion temperature is 250 ° C, and the screw speed is 500 rpm to obtain a high CTI, low temperature super tough flame retardant PC material, and then injection-molded to make test specimens for performance testing.

[0068] Table 1 - Contents of raw material components

[0069]

[0070]

[0071] Note: " / " means that the ingredient is not contained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com