High-CTI and low-temperature super-tough flame-retardant PC material and preparation method thereof

A low-temperature, super-tough technology, applied in the field of polymer materials, can solve problems such as insufficient insulation performance, and achieve the effect of improving low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

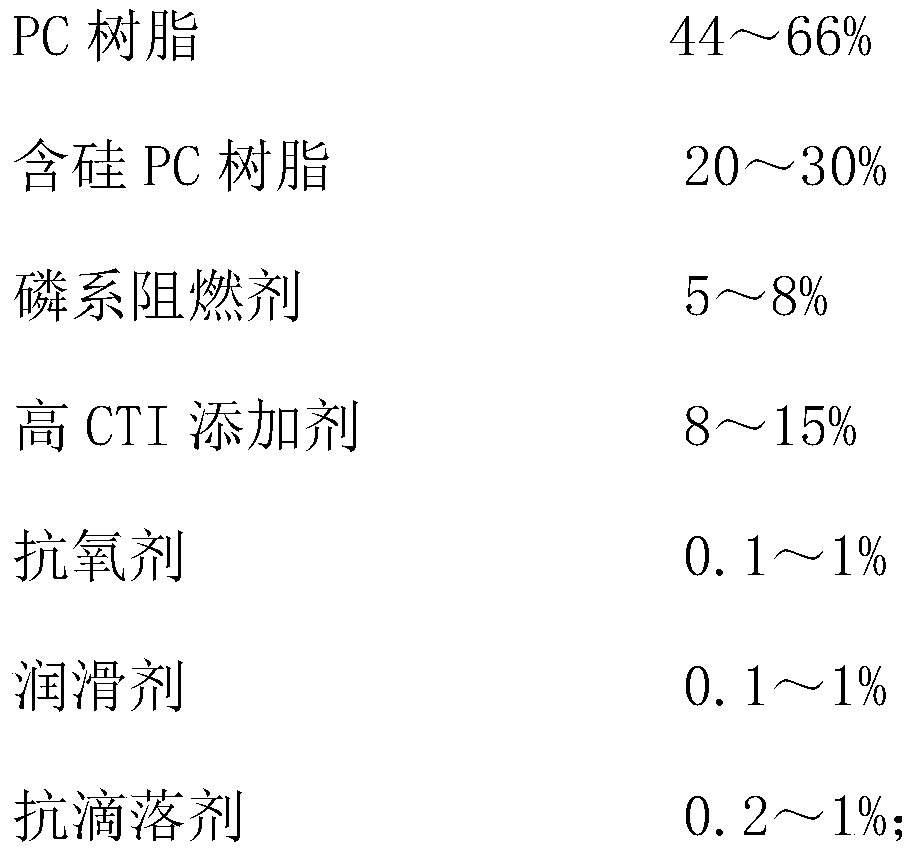

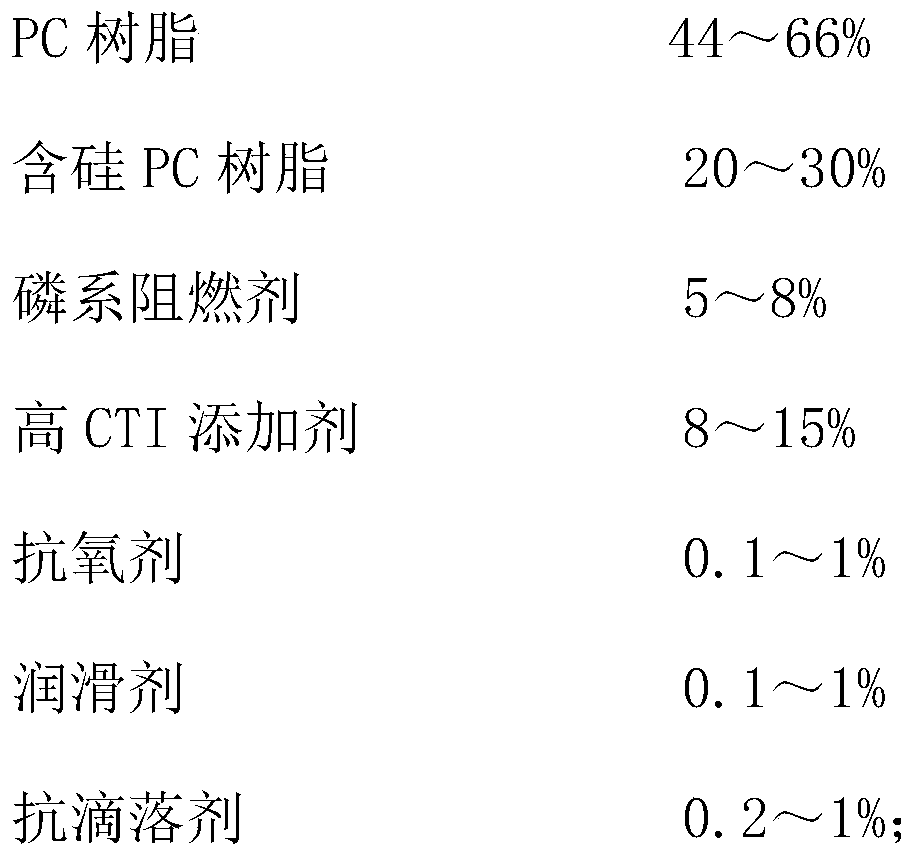

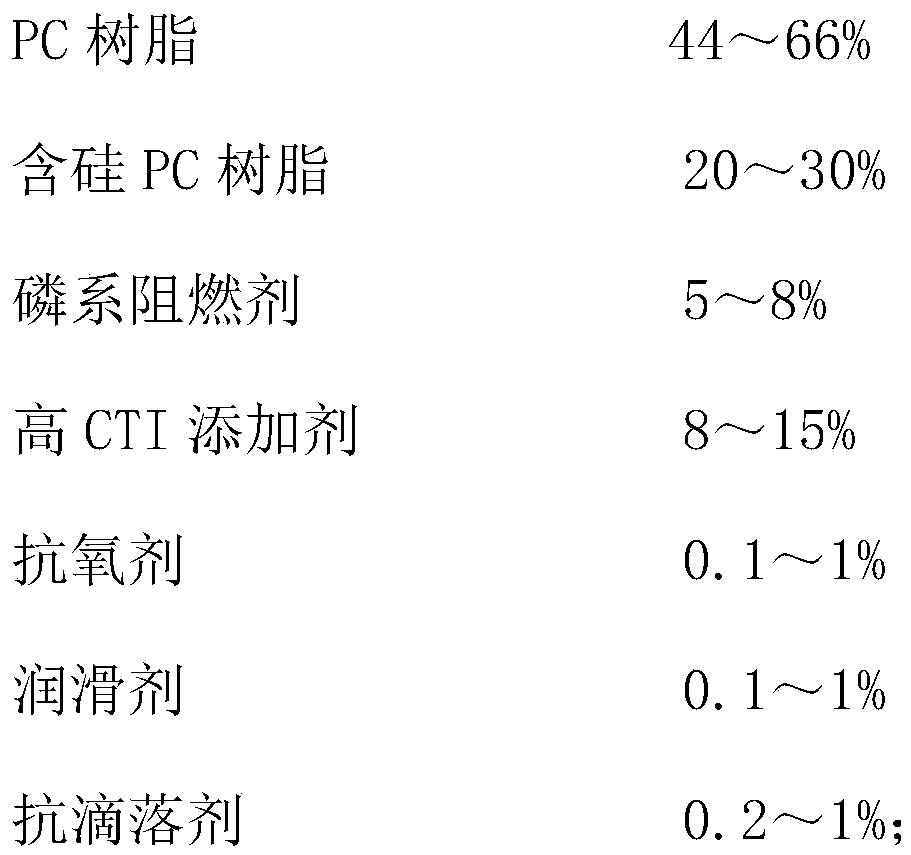

[0043] The method for preparing a high-CTI, low-temperature super-tough flame-retardant PC material includes the following steps:

[0044] A. Weigh PC resin, silicon-containing PC resin, phosphorous flame retardant, high CTI additives, antioxidants, lubricants and anti-dripping agents by weight percentage for use;

[0045] B. Mix the components weighed in step A uniformly;

[0046] C. After pelletizing the mixture obtained in step B through twin-screw extrusion, a high-CTI, low-temperature super-tough flame-retardant PC material is obtained.

[0047] By adding low-molecular-weight and medium-particle high-insulating PTFE polymers as high-CTI additives to the system, the CTI of the material is improved, and phosphorus-based flame retardants are added to improve the flame-retardant performance of the material, and high-molecular-weight PTFE is used as anti-drip The agent can play the role of preventing dripping and stabilizing flame retardant. In addition, adding silicon-containing PC r...

Embodiment 1-12 and comparative example 1-3

[0064] A high-CTI, low-temperature super-tough flame-retardant PC material, prepared according to the following steps:

[0065] (1) Calculated according to weight percentage, each raw material is weighed according to the content of raw material components in Table 1 for use;

[0066] (2) Add the components weighed in step (1) into the mixing tank and mix evenly to obtain a mixture;

[0067] (3) Add the mixture obtained in step (2) to a twin-screw extruder, and perform twin-screw extrusion granulation. The extrusion temperature is 250°C and the screw speed is 500rpm to obtain a high-CTI, low-temperature super-tough flame retardant The PC material is then injection-molded to produce test strips for performance testing.

[0068] Table 1-Raw material component content

[0069]

[0070]

[0071] Note: " / " means that the ingredient is not contained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com