Feeding device and feeding method in anodizing process of aluminum die casting

An aluminum die-casting and anodic oxidation technology, which is applied in anodic oxidation, electrolytic coating, electrolytic components, etc., can solve the problems of lack of blanking equipment for aluminum die-casting parts, and achieve the effects of easy collection, improved production efficiency, and optimized collection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Those skilled in the art will appreciate that these descriptions are only descriptive and exemplary, and should not be construed as limiting the protection scope of the present invention.

[0026] It should be noted that similar reference numerals denote similar items in the following figures, therefore, once an item is defined in one figure, it may not be further defined and explained in subsequent figures.

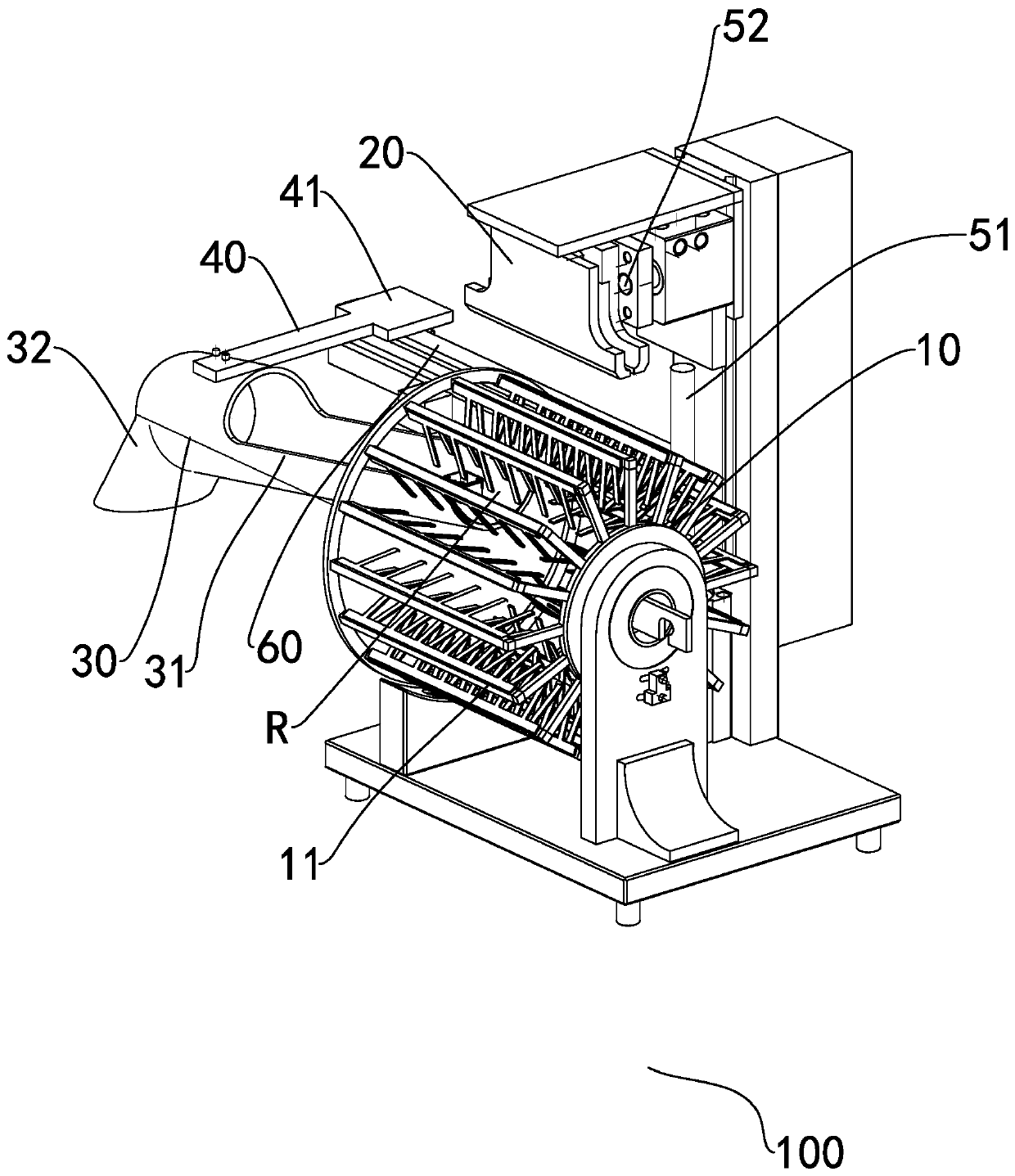

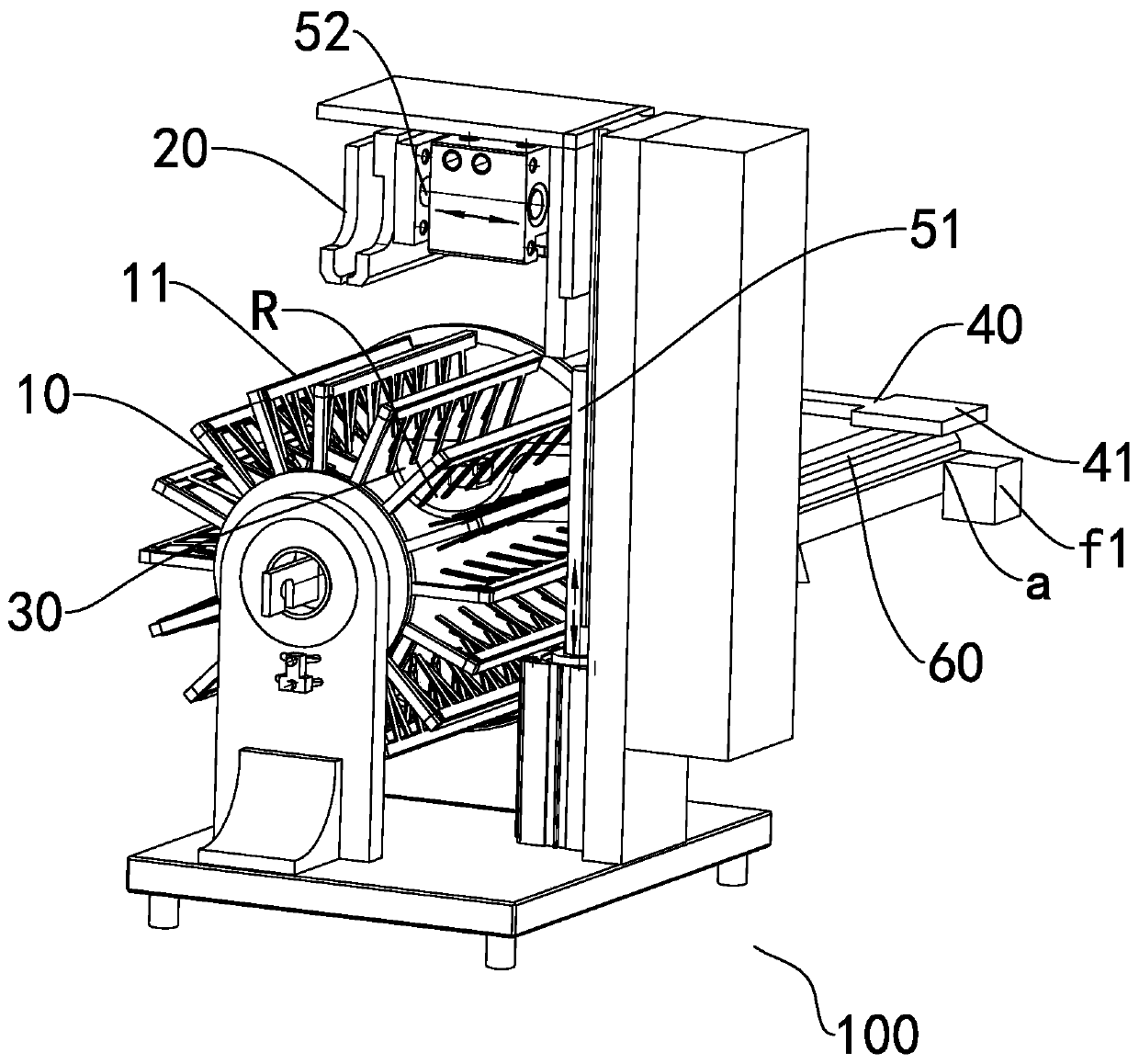

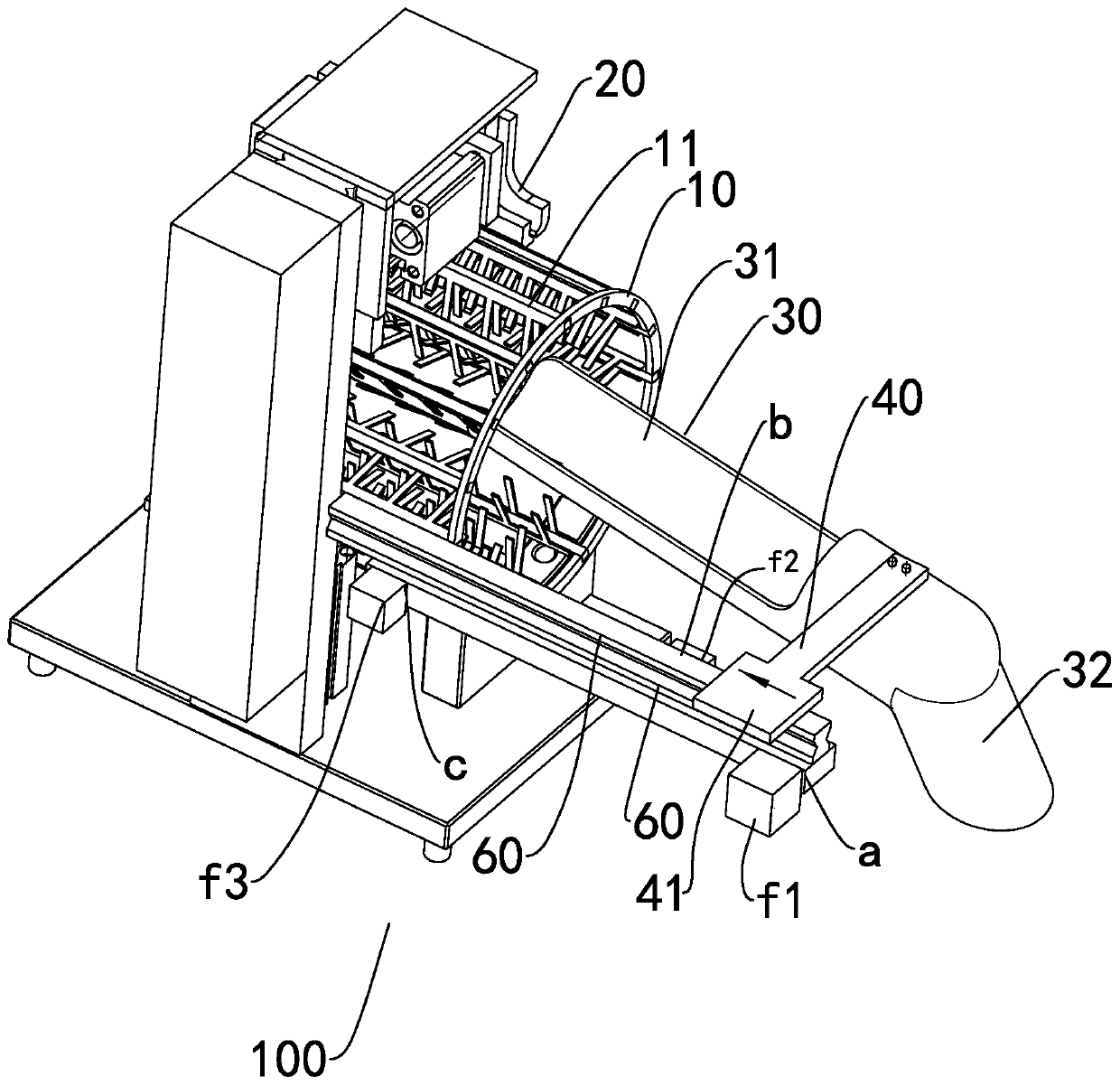

[0027] Such as Figure 1 to Figure 4 As shown, the blanking equipment 100 in the anodizing process of aluminum die castings includes a cylindrical hanger 10 for hanging aluminum die castings, a clamping assembly 20, and is used to collect the fallen aluminum die castings P and guide the aluminum die castings P to tilt The material receiving part 30 is downward, and the cylindrical hanger 10 includes a plurality of horizontal hanging parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com