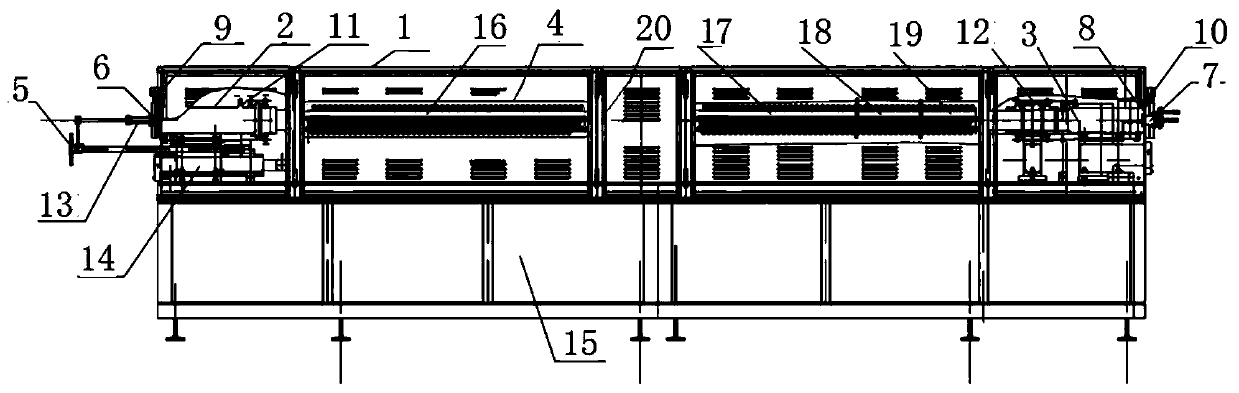

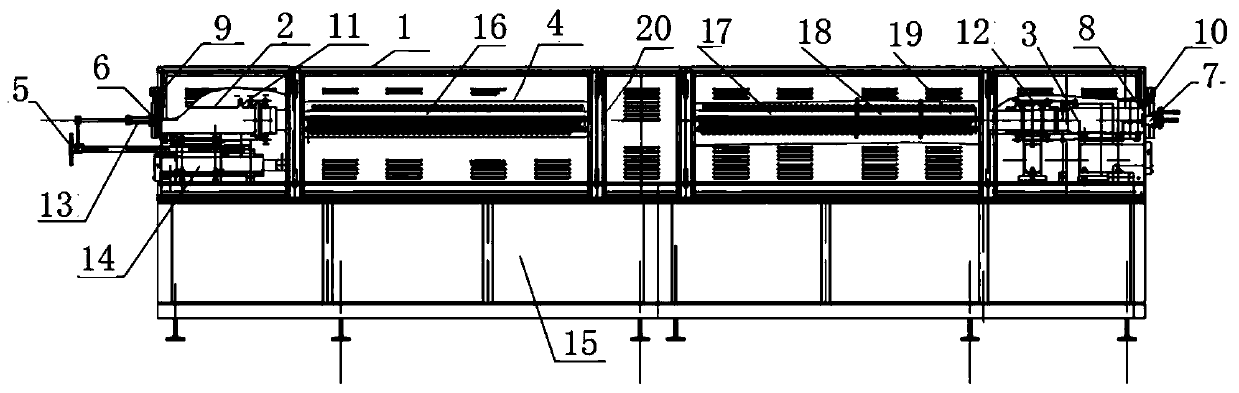

Germanium reduction directional crystallization furnace and crystallization method

A technology of directional crystallization and crystallization, which is applied in the field of metallurgy, can solve the problems of large equipment footprint, small production capacity of a single unit, and high energy consumption, and achieve the effects of compact structure design, easy operation, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The graphite boat contains germanium dioxide, and then it is pushed to the low-temperature reduction zone of the first tube section for reduction at a temperature of 680°C. The reduction time in this zone is long, and most of the germanium oxide is reduced to metal germanium powder. The bottom part of the graphite boat is not reduced through. The germanium dioxide continues to run until the temperature of the high-temperature reduction section of the second pipe section is 790°C, where it is rapidly reduced, then runs to the temperature of the third pipe section and melts at 1040°C, and finally enters the fourth pipe section at a constant temperature of 970°C to make the germanium liquid uniform Distributed in the graphite boat, crystallization is carried out slowly at the advancing speed of 4mm / min.

Embodiment 2

[0032] The germanium dioxide contained in the graphite boat is pushed to the low-temperature reduction zone of the first tube section for reduction at a temperature of 750°C. The reduction time in this zone is long, and most of the germanium oxide is reduced to metal germanium powder. The unreduced germanium dioxide at the bottom of the graphite boat The germanium oxide continues to run until the temperature in the high-temperature reduction section of the second pipe section is 880°C, where it is quickly reduced, then runs to the temperature of the third pipe section and melts at 940°C, and finally enters the fourth pipe section at a constant temperature of 1010°C, so that the germanium liquid is evenly distributed in the In the graphite boat, the crystallization was carried out slowly at a propulsion speed of 4 mm / min.

Embodiment 3

[0034] The germanium dioxide contained in the graphite boat is pushed to the low-temperature reduction zone of the first tube section for reduction at a temperature of 715°C. The reduction time in this zone is long, and most of the germanium oxide is reduced to metal germanium powder. The germanium oxide continues to run until the temperature in the high-temperature reduction section of the second pipe section is 835°C, where it is rapidly reduced, then runs to the temperature of the third pipe section and melts at 980°C, and finally enters the fourth pipe section at a constant temperature of 1010°C, so that the germanium liquid is evenly distributed in the In the graphite boat, the crystallization was carried out slowly at a propulsion speed of 5 mm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com