Dyeing process for superfine polyester denier fiber yarn

A yarn dyeing and ultra-fine denier technology, applied in the field of yarn dyeing, can solve the problems of increasing dyeing cost, and achieve the effects of improving dyeing speed, enhancing color fastness and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

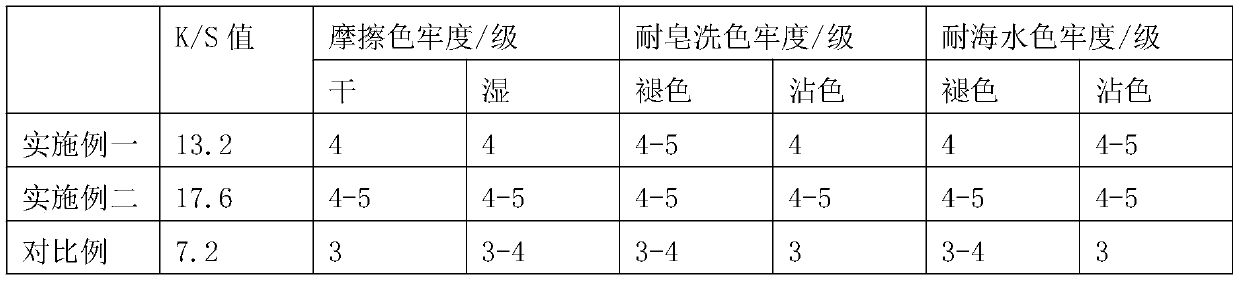

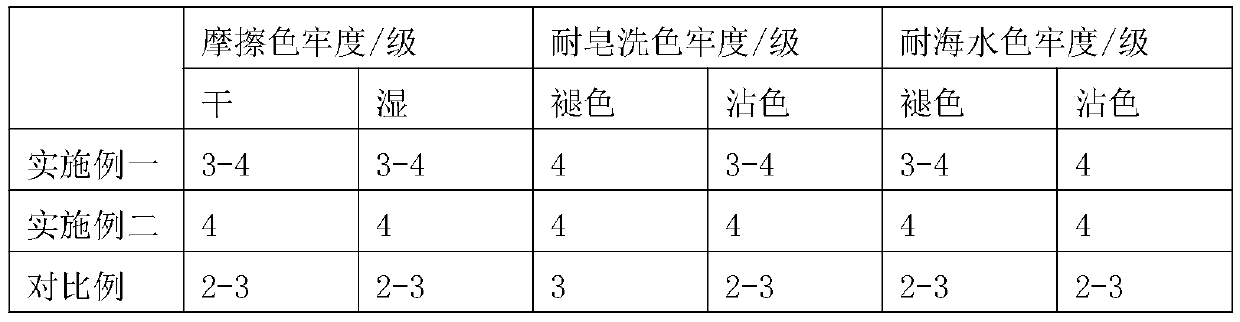

Examples

Embodiment 1

[0029] A kind of dyeing process of polyester ultrafine denier fiber yarn involved in the present embodiment comprises the following steps: Step 1, pre-shrinking; Step 2, loose winding; Step 3, cage loading; Step 4, pretreatment before oil removal; Step 5, dyeing; Step 6, color fixing; Step 7, washing; Step 8, drying.

[0030] In the above step 1, the polyester superfine denier fiber is vacuum steamed, treated at 60°C for 5-10 minutes, and then heated to 85-95°C at a heating rate of 2-3°C / min, and kept for 10- After 15 minutes, continue to raise the temperature to 105-110°C at a heating rate of 0.5-1°C / min, keep it for 5-10 minutes, then raise the temperature to 120-125°C at a heating rate of 1.5-2°C / min, and keep it for 10-15 minutes.

[0031] In the above step 2, the pre-shaped polyester ultrafine denier fiber yarn will be formed into a loose bobbin by using loose winding; the polyester yarn will be turned to plastic as required by the loose winding machine. on the bobbin, a...

Embodiment 2

[0046] A kind of dyeing process of polyester ultrafine denier fiber yarn involved in the present embodiment comprises the following steps: Step 1, pre-shrinking; Step 2, loose winding; Step 3, cage loading; Step 4, pretreatment before oil removal; Step 5, dyeing; Step 6, color fixing; Step 7, washing; Step 8, drying.

[0047] In the above step 1, the polyester superfine denier fiber is vacuum steamed, treated at 60°C for 5-10 minutes, and then heated to 85-95°C at a heating rate of 2-3°C / min, and kept for 10- After 15 minutes, continue to raise the temperature to 105-110°C at a heating rate of 0.5-1°C / min, keep it for 5-10 minutes, then raise the temperature to 120-125°C at a heating rate of 1.5-2°C / min, and keep it for 10-15 minutes. The polyester microfiber of DTY 288F 150D is used.

[0048] In above-mentioned step 2, be to adopt the mode of loose type winding, the polyester superfine denier fiber yarn after presetting is formed into loose bobbin yarn, and the overfeed amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com