Large-span variable-section beam

A variable-section beam and large-span technology, applied in the direction of girders, joists, truss beams, etc., can solve problems such as insufficient shear bearing capacity, reduced beam section height, and large proportion of structural self-weight, so as to save engineering cost, The force is clear and the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

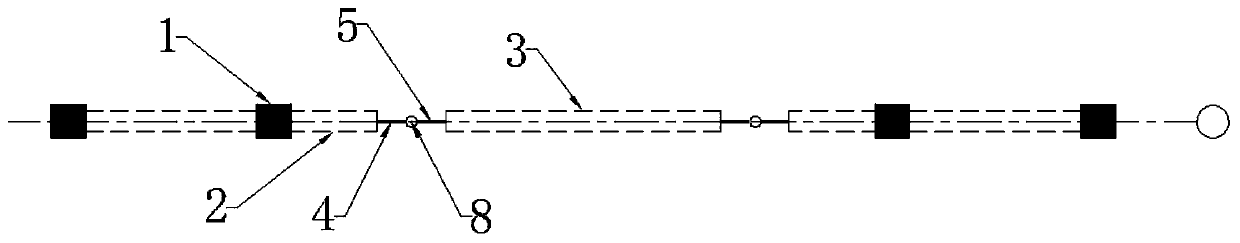

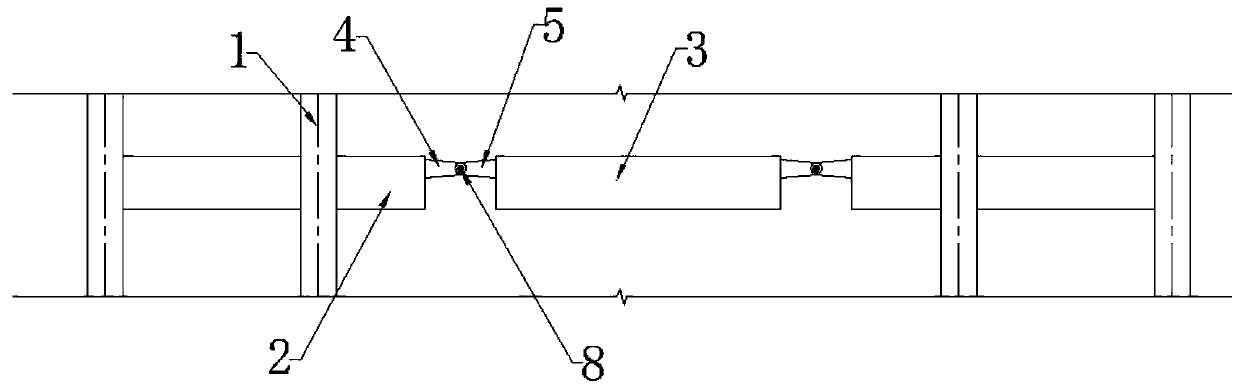

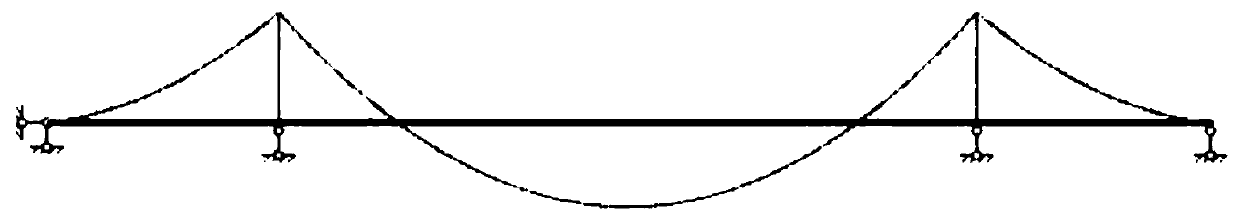

[0024] Such as figure 1 and figure 2 As shown, a large-span variable-section beam includes a column 1, a cantilever section 2, a simply supported section 3 and a short beam section. The cantilever section 2 is located on both sides and is fixedly connected to the column 1. The simply supported section 3 is located in the middle and its two sides The ends are respectively connected with two cantilever sections 2 through short beam sections. Cantilever section 2 and simply supported section 2 are both made of reinforced concrete. The short beam section includes the cantilever side short beam section 4 and the simply supported side short beam section 5, the cantilever side short beam section 4 and the simply supported side short beam section 5 are all shaped steel, the cantilever side short beam section 4 and the simply supported side short beam section 5 are connected by a pin shaft 8, the end of the short beam section 4 on the cantilever side extends to the inside of the can...

Embodiment 2

[0027] Such as Figure 5 and Figure 6 As shown, a large-span variable-section beam includes a column 1, a cantilever section 2, a simply supported section 3 and a short beam section. The cantilever section 2 is located on both sides and is fixedly connected to the column 1. The simply supported section 3 is located in the middle and its two sides The ends are respectively connected with two cantilever sections 2 through short beam sections. Cantilever section 2 and simply supported section 2 are both made of reinforced concrete. The short beam section includes the cantilever side short beam section 4 and the simply supported side short beam section 5, the cantilever side short beam section 4 and the simply supported side short beam section 5 are all shaped steel, the cantilever side short beam section 4 and the simply supported side short beam section 5 are connected by a pin shaft 8, the end of the short beam section 4 on the cantilever side extends to the inside of the ca...

Embodiment 3

[0032] Such as Figure 7 and Figure 8 As shown, a large-span variable-section beam includes a column 1, a cantilever section 2, a simply supported section 3 and a short beam section. The cantilever section 2 is located on both sides and is fixedly connected to the column 1. The simply supported section 3 is located. One end of the 3 is connected to the cantilever section 2 on one side through a short beam section, and the other end of the simply supported section 3 is fixedly connected to the cantilever section 2 on the other side. Cantilever section 2 and simply supported section 2 are both made of reinforced concrete. The short beam section includes the cantilever side short beam section 4 and the simply supported side short beam section 5, the cantilever side short beam section 4 and the simply supported side short beam section 5 are all shaped steel, the cantilever side short beam section 4 and the simply supported side short beam section 5 are connected by a pin shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com