Automobile urea box mounting structure

A technology of installation structure and urea tank, which is applied in the field of machinery, can solve problems such as inconsistent weight characteristics, affecting appearance and strength, and hidden safety hazards of fixed performance, so as to achieve the effects of reducing fuel consumption, improving support performance, and highlighting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

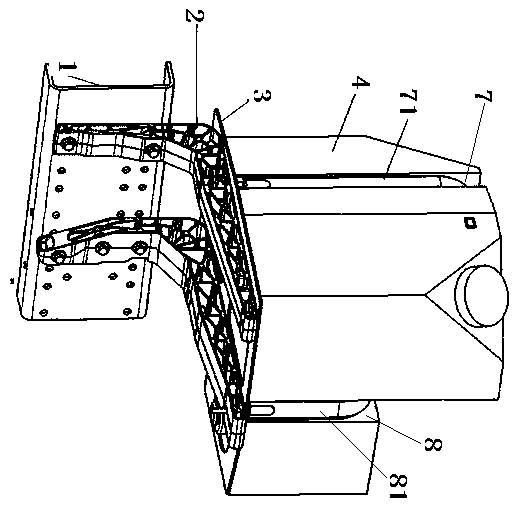

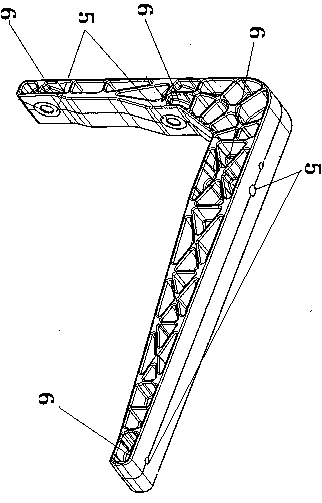

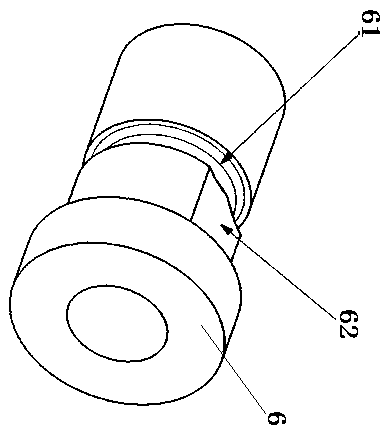

[0009] combine Figure 1-Figure 4 As shown, an automobile urea tank installation structure of the present invention includes a bracket 2 installed on the vehicle frame 1, a tray 3 is installed on the bracket 2, and a urea tank 4 is installed on the tray 3, and the bracket 2 is die-cast and has left and right ends A number of L-shaped aluminum alloy brackets with hollow grooves are provided with a number of installation holes 5 along the center line of the width direction of the bracket 2. Steel sleeves 6 are arranged in the installation holes 5. The steel sleeves 6 are placed in the mold in advance when the aluminum alloy bracket is die-casted. Due to the higher melting point of steel, the steel sleeve will be directly embedded in the installation hole when casting molten aluminum. The steel sleeve 6 is a cylindrical circular frustum T-shaped structure, and an anti-detachment groove 61 is provided around the cylindrical surface of the steel sleeve. An anti-rotation plane 62 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com