Garbage drying device for garbage incineration power generation

A technology of waste incineration and drying equipment, which is applied in the direction of drying, drying machines, heating devices, etc., which can solve the problems of increasing the cost of incinerating waste, too simple rotating rod, and reducing the dehydration effect of waste, so as to facilitate discharge and improve Rotation effect, effect of improving dehydration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

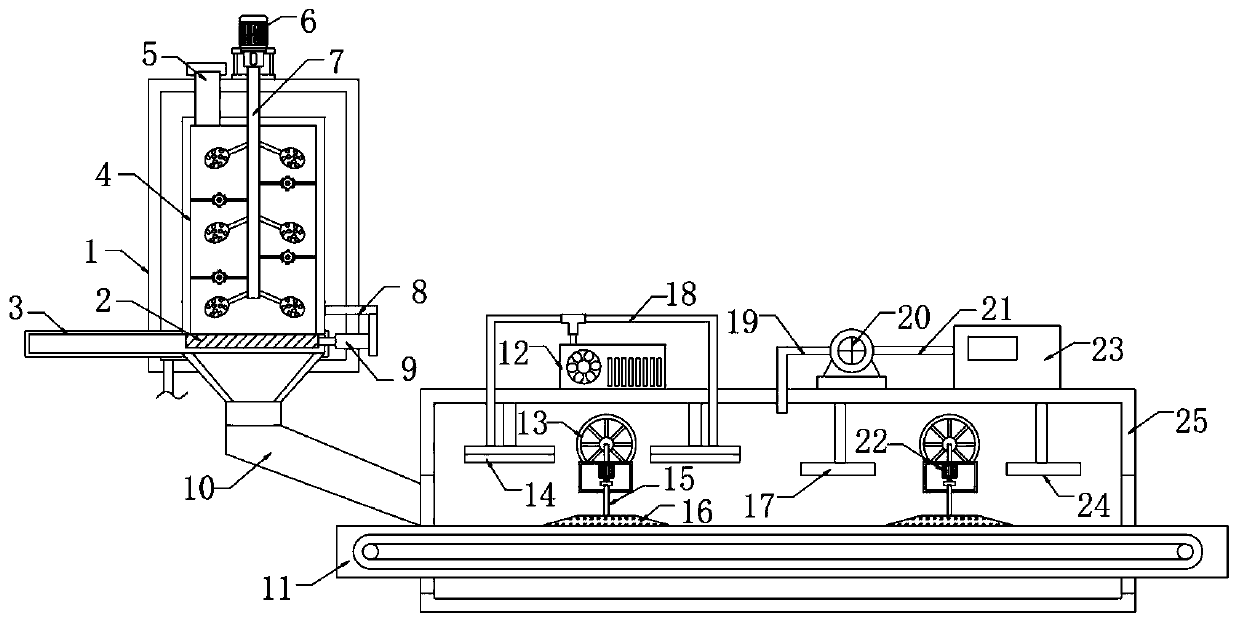

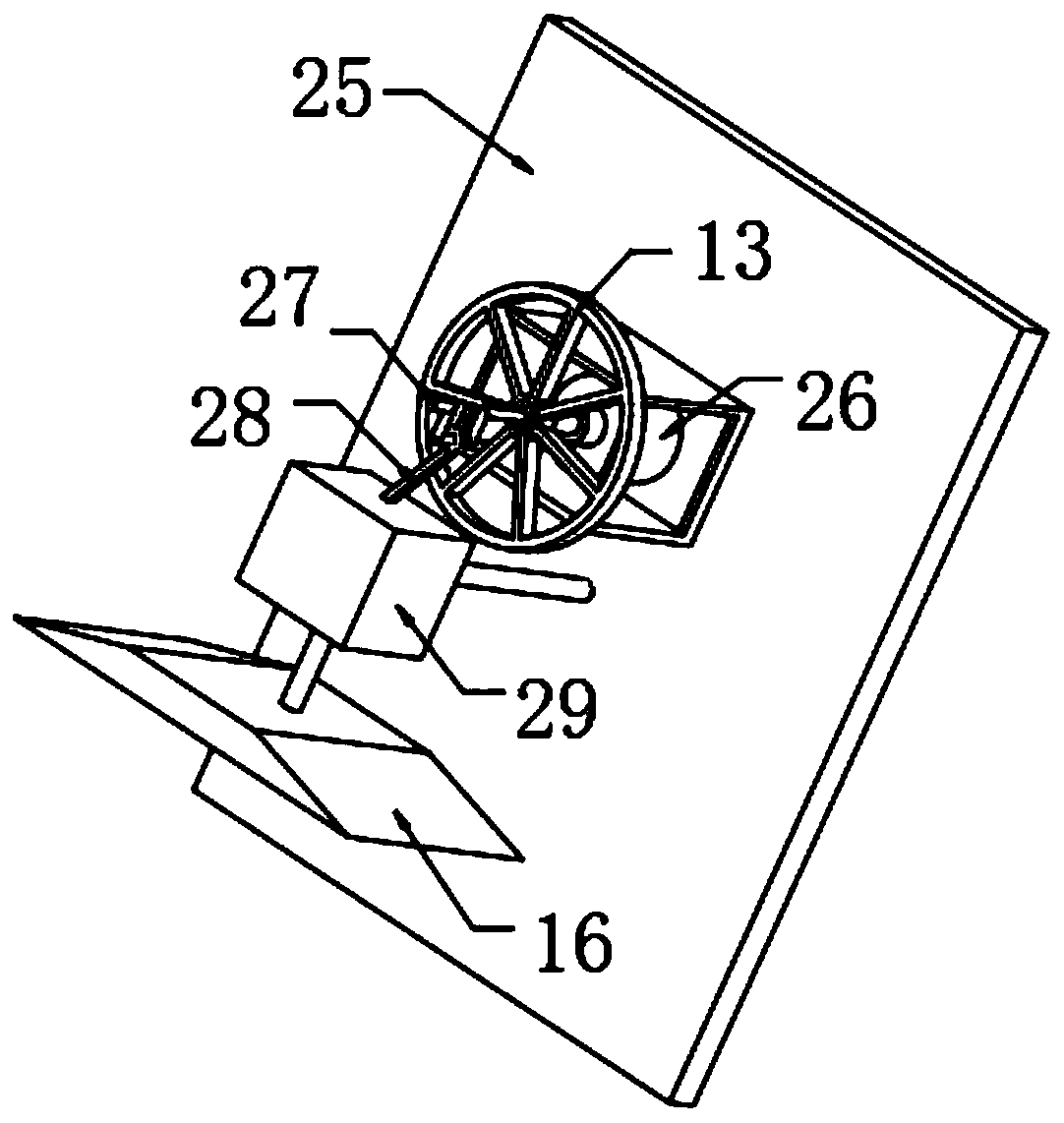

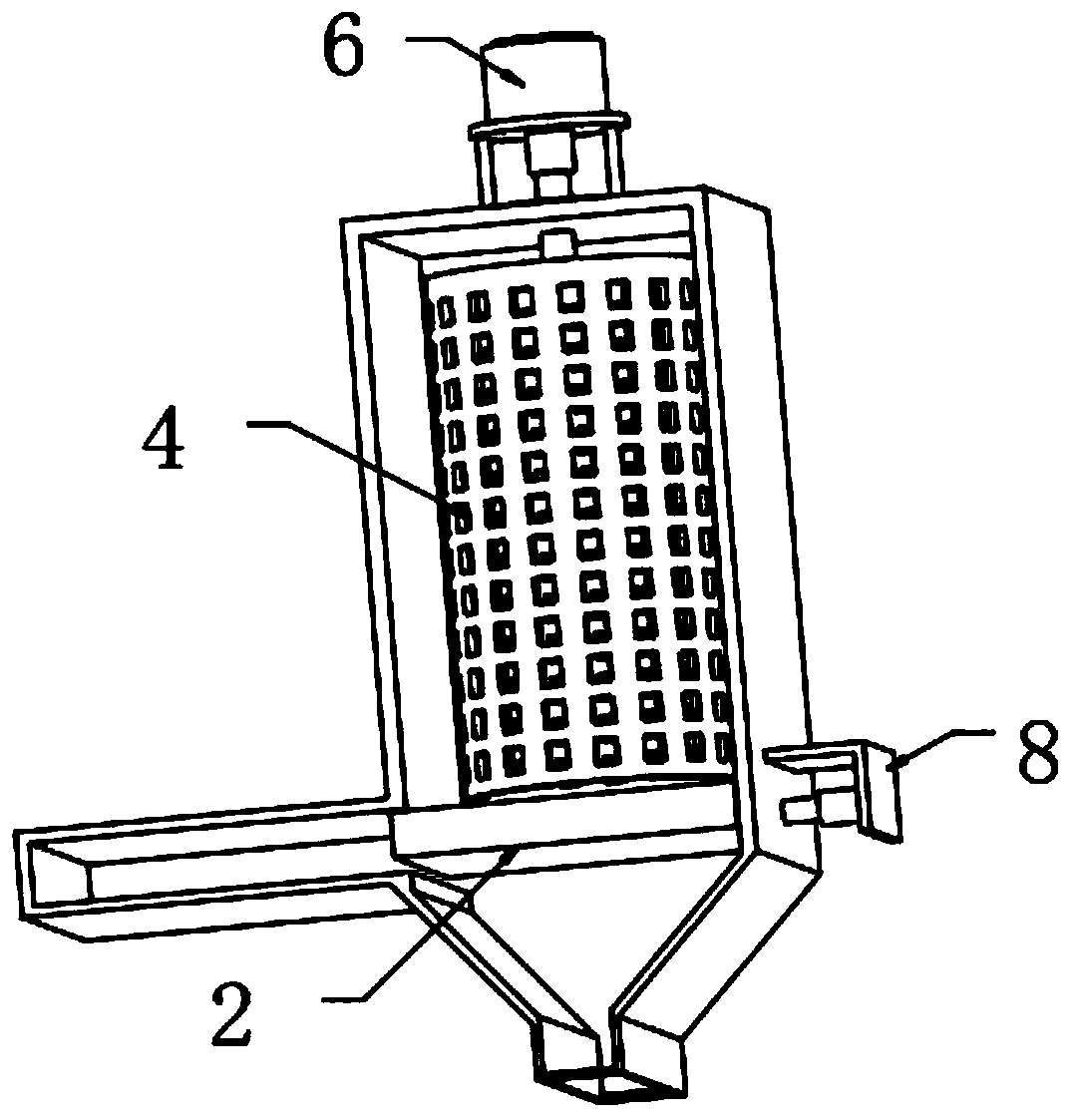

[0031] refer to Figure 1-4 , a garbage drying device for waste incineration power generation, comprising a dehydration box 1 and a drying box 25, the inner wall of the dehydration box 1 is welded with a dehydration cylinder 4, and the top outer wall of the dehydration box 1 is fixed with a first motor 6 by screws, the second The output shaft of a motor 6 is connected with the first rotating rod 7 through a shaft coupling, and the outer wall of the first rotating rod 7 is welded with equidistantly distributed stirring plates 31, and the outer walls of the stirring plate 31 are welded with equidistantly distributed stirring plates 31. Protrusion, the outer wall of the first rotating rod 7 and the inner wall of the dehydration cylinder 4 are welded with a connecting rod 30, and the outer wall of the connecting rod 30 is connected with a runner 32 through a bearing, and the outer wall of one side of the dehydration box 1 is fixed with a connecting box 3 by screws , and one side o...

Embodiment 2

[0038] refer to Figure 5 , a garbage drying device for waste incineration power generation, also includes a purifier 34 fixed to the outer wall of one side of the dehydration box 1 by screws, the input end of the purifier 34 and the inner wall of one side of the dehydration box 1 are connected by the same flange Airway 33.

[0039] Connect the equipment to the power supply, put the garbage into the dehydration cylinder 4 from the feed port 15, turn on the first motor 6, and the first motor 6 drives the first rotating rod 7 to rotate, and then the stirring plate 31 and the runner 32 can be rotated. Fully rotate and dehydrate the garbage. After the dehydration is completed, connect the hydraulic rod 9 to the hydraulic system. When the length of the hydraulic rod 9 is adjusted, the baffle plate 2 is pushed out, and the garbage is discharged from the feeding chute 10. The conveying table 11 is opened, and the garbage starts to be conveyed , turn on the hot air blower 12, dry the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com