High-speed low-voltage electrooptical modulator based on lithium niobate-silicon wafer

An electro-optical modulator, lithium niobate technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems that pure silicon-based modulators are difficult to meet high speed, low voltage and low loss, achieve high refractive index, avoid etching , the effect of compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

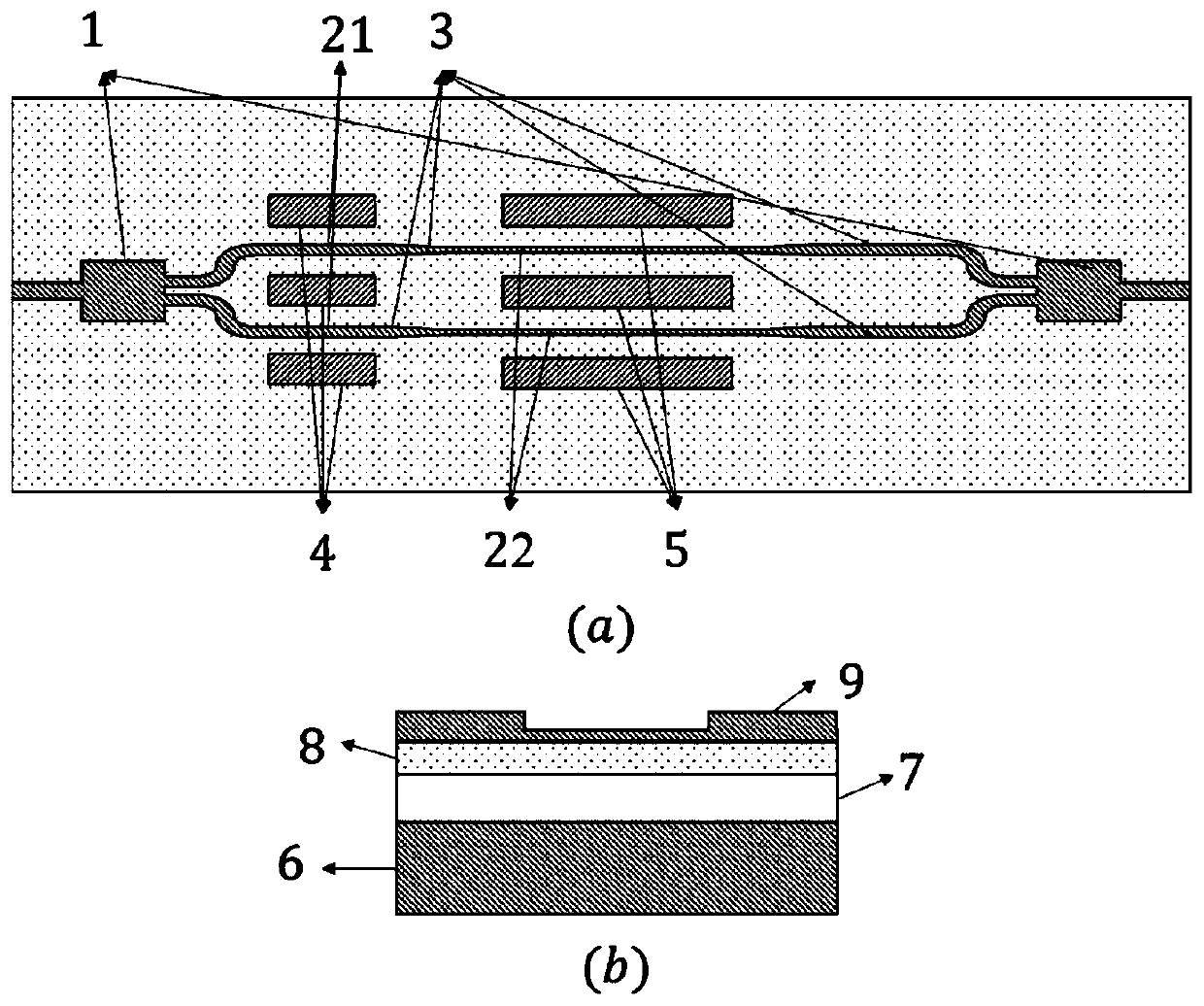

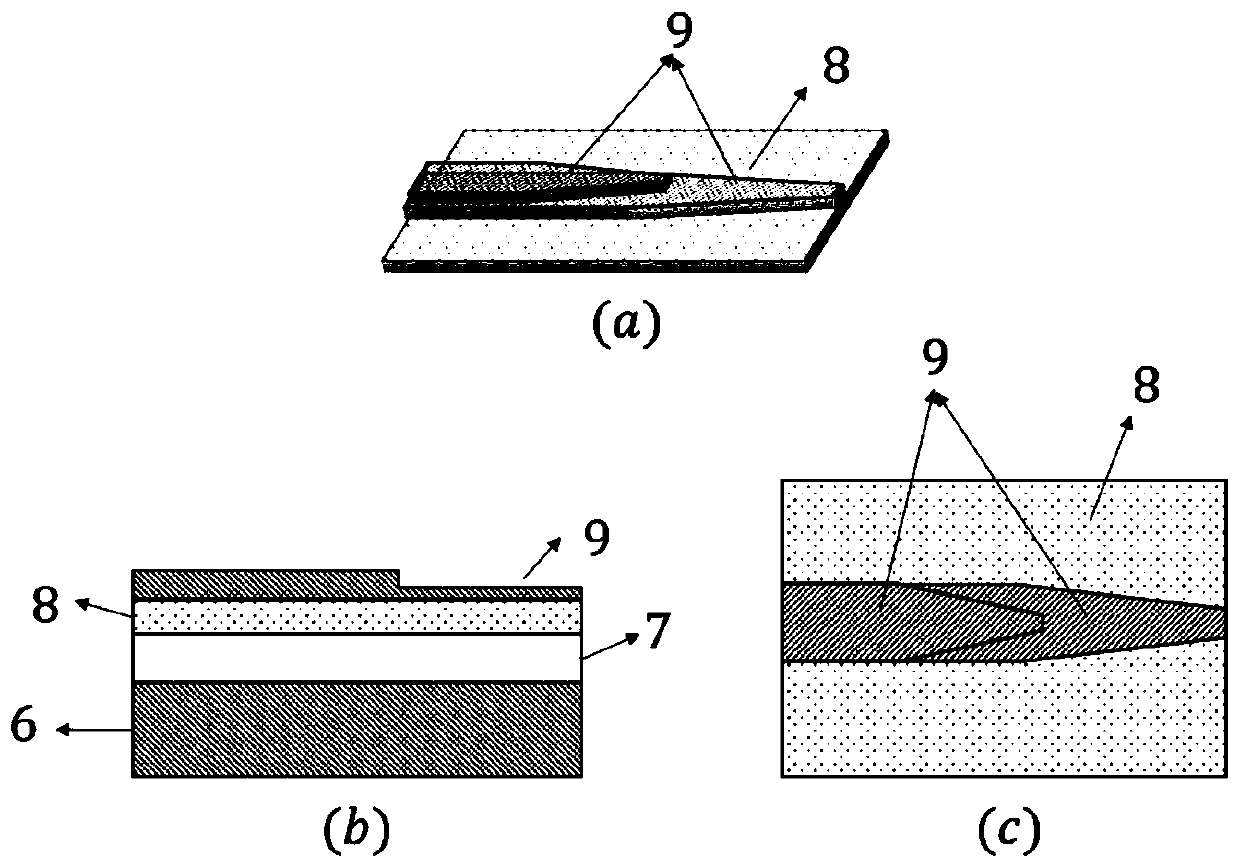

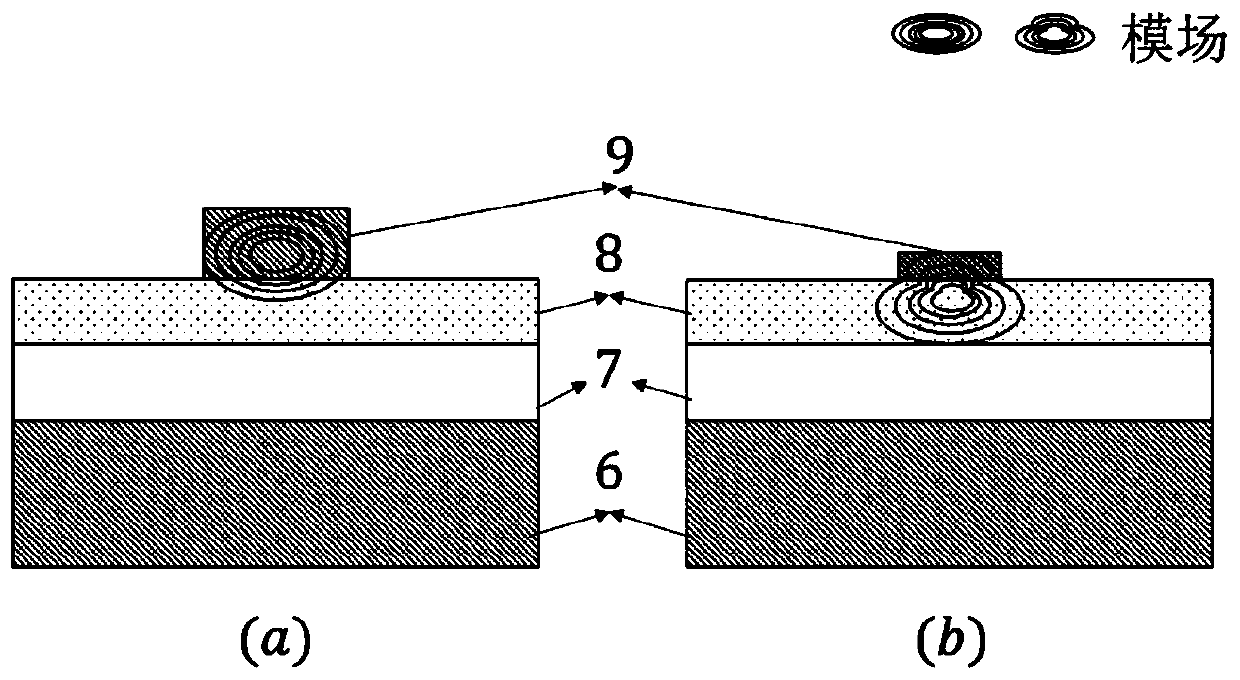

[0029]The basic structure of the present invention is a Mach-Zehnder modulator, including two multimode interferometers 1, two mode-spot converters 3, two thermally adjustable phase-shifting arms 21, two electrically adjustable phase-shifting arms 22, a DC bias Electrode 4 and RF electrode 5. The multimode interferometer is a 1×2 multimode interferometer, and the two multimode interferometers 1 serve as a wave combiner and a wave splitter respectively. The two output ports of the multiplexer are respectively connected to two thermally adjustable phase-shifting arms 21, and the two thermally adjustable phase-shifting arms 21 are respectively connected to one end of two mode-spot converters 3, and the two mode-spot converters 3 The other ends are respectively connected to two electrically controlled phase-shifting arms 22, and the two electrically controlled phase-shifting arms 22 are respectively connected to two modulus converters, and the two modulus converters 3 are finally ...

Embodiment 2

[0031] For the bias point control method of the high-speed, low-voltage modulator, in the embodiment of the present invention, the thermally adjustable phase-shift arm 21 is located in the high-refractive index region, and is used for the bias point control of the high-speed, low-voltage modulator. Therefore, from one port of the modulator to the other port, the waveguide structure components are the multimode interferometer 1 , the thermally tuned phase-shifting arm 21 , the mode-spot converter 3 , the electrically tuned phase-shifting arm 22 , and the multimode interferometer 1 .

Embodiment 3

[0033] In another embodiment of the present invention, the thermal phase shifter 21 is located in the low-refractive index region for bias point control of a high-speed, low-voltage modulator. Therefore, from one port of the modulator to the other port, the waveguide structure components are the multimode interferometer 1, the mode speckle converter 3, the thermal phase shifter 21, the electrical phase shifter 22, and the multimode interferometer 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com