Parallel charging module and DC screen system applying same

A charging module and parallel connection technology, applied in the field of DC panel system, can solve the problems of difficult replacement and reconstruction of switching stations, increased equipment maintenance workload, low reliability, etc., to ensure the continuity of power supply, make up for power supply defects and maintenance defects, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

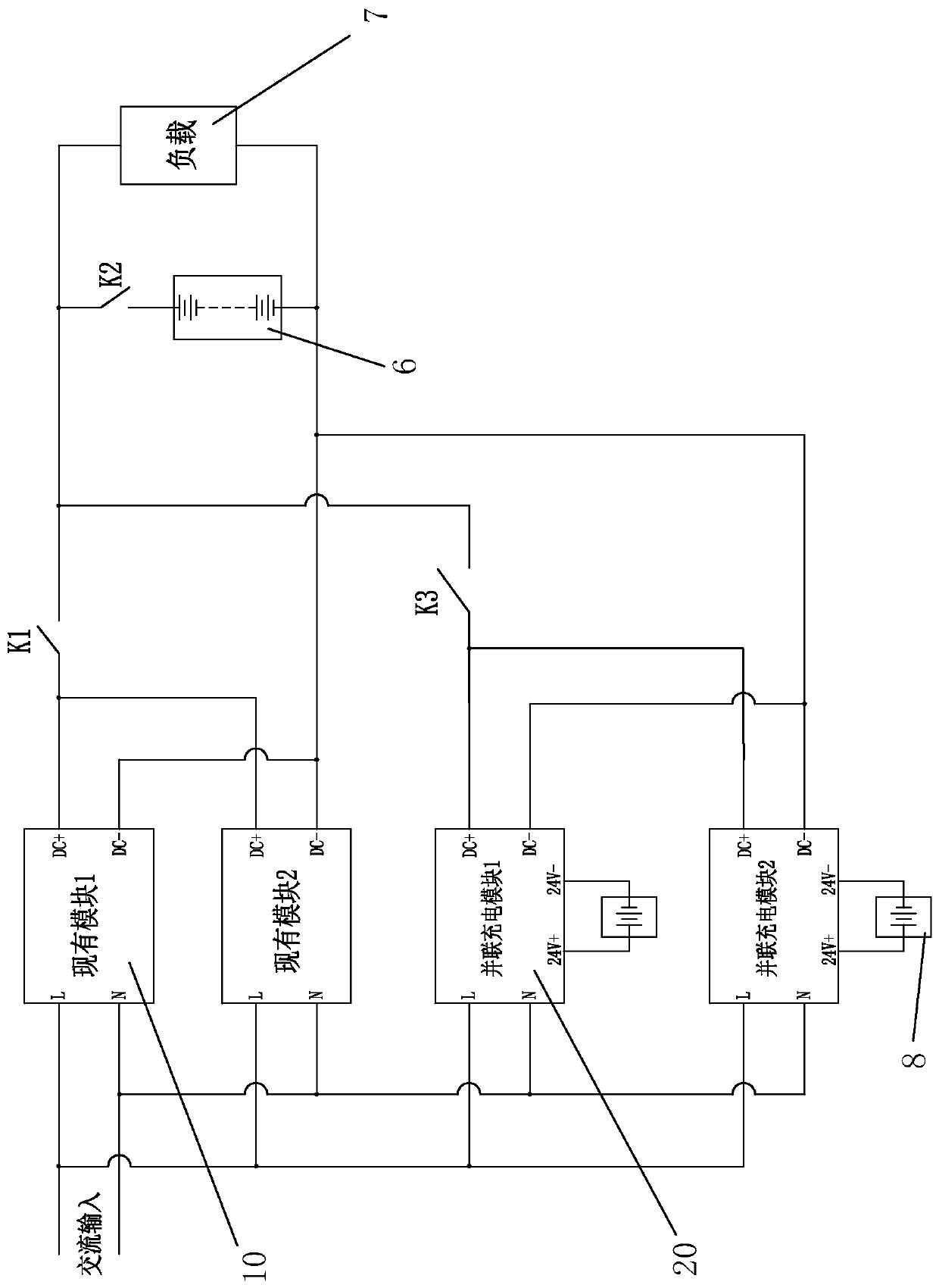

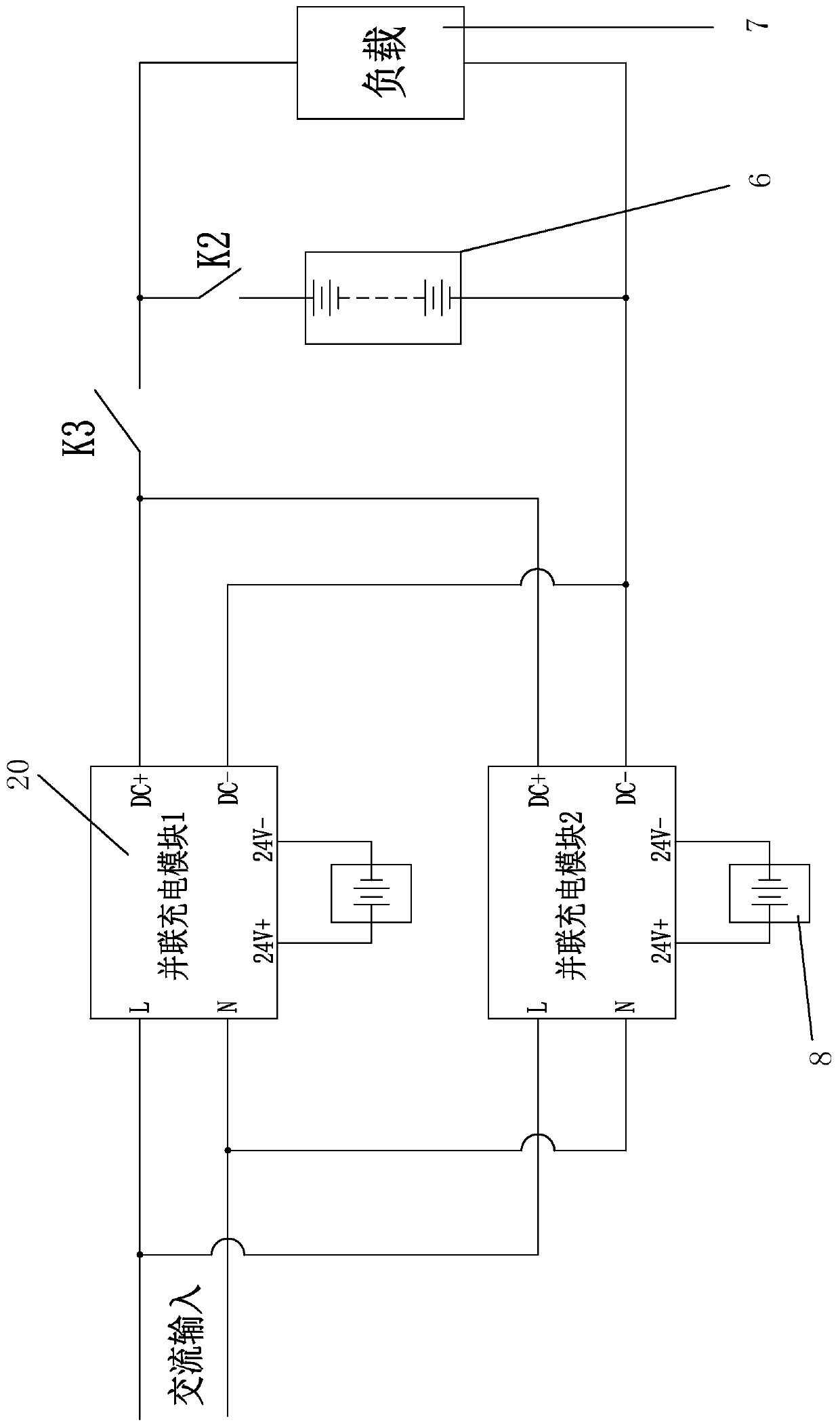

[0029] see Image 6As shown, a parallel charging module 20 disclosed by the present invention includes an electromagnetic compatibility EMC part 1, a 1# AC / DC AC / DC converter 2, a 2# AC / DC AC / DC converter 3, and a DC / DC DC converter 4 And DSP control chip 5. The input terminal of EMC part 1 is for connection with the input AC power supply. The input end of 1# AC / DC converter 2 is connected in parallel with the input end of 2# AC / DC converter 3 , and is connected to the output end of EMC part 1 . The output terminal of 1#AC / DC converter 2 outputs high voltage, which supplies high voltage battery pack 6 (it can be 18 12V battery packs or 108 2V battery packs) and load 7. 2#AC / DC AC / DC converter 3 The output end of the output terminal outputs low voltage, and one branch is supplied to the low voltage battery pack 8 (24V can be formed by two 12V batteries), and the other branch is connected with the input end of the DC / DC converter 4. The output end of the DC / DC converter 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com