Vibration control method of sensorless permanent magnet synchronous motor

A permanent magnet synchronous motor and sensor technology, which is applied in motor control, motor generator control, AC motor control, etc., can solve the problems of signal-to-noise ratio reduction, inability to be filtered out by filters, high-frequency harmonic component position deviation information, etc. , to suppress the influence of motor vibration and noise, improve acoustic stealth ability, and be easy to realize in engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

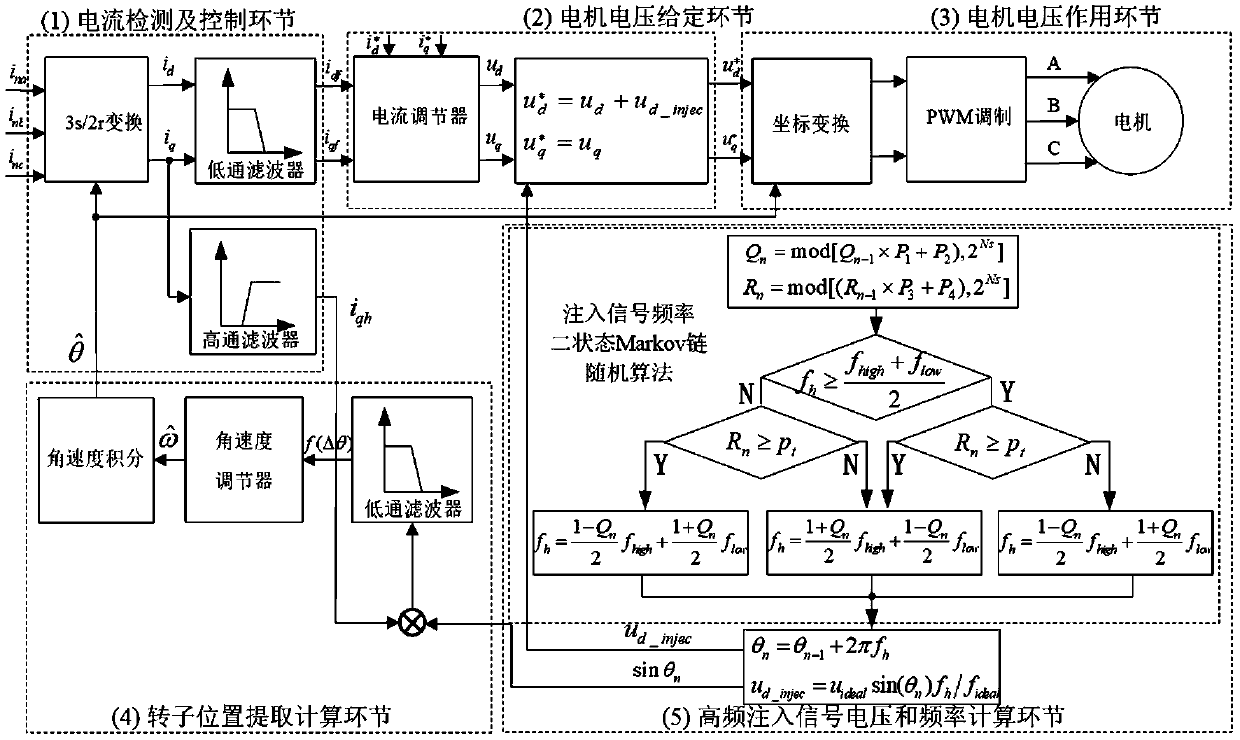

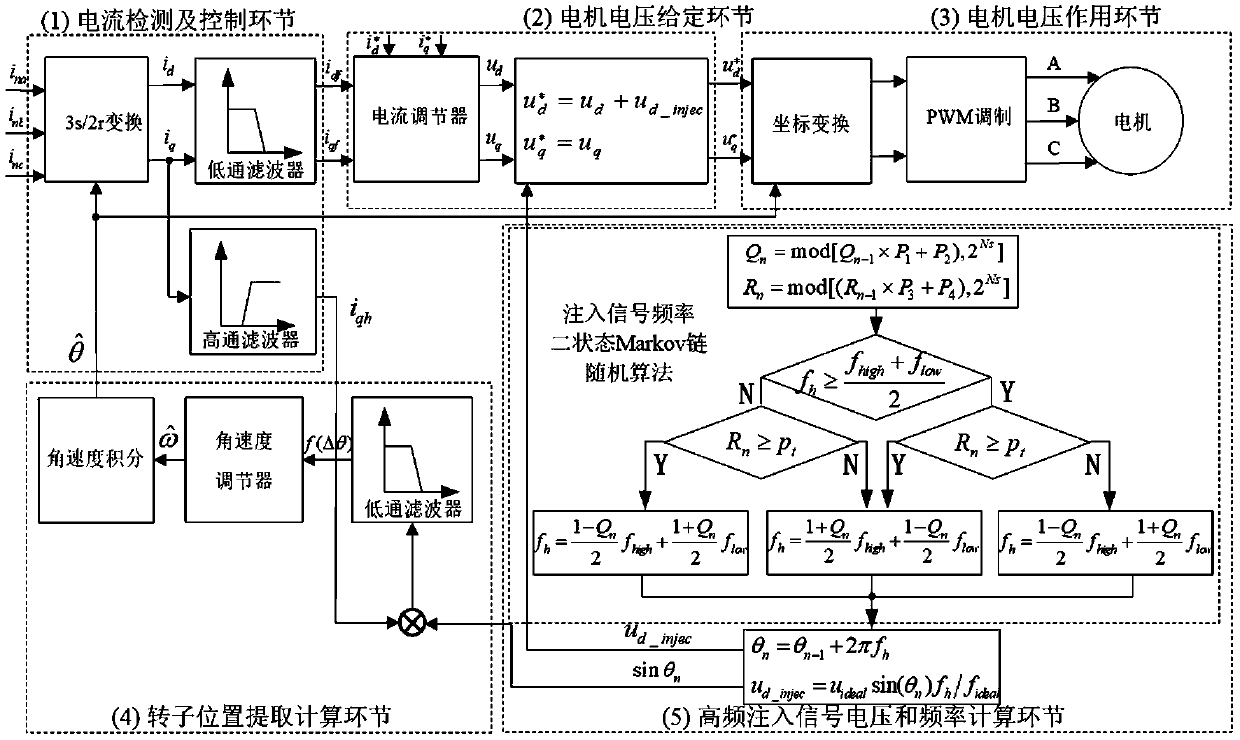

[0041] Such as figure 1 As shown, the present invention is used for a three-phase or 3N-phase permanent magnet propulsion synchronous motor powered by a voltage-type inverter. The calculation link 4 is composed of the high-frequency injection signal voltage and frequency calculation link 5.

[0042] The control method includes the following steps:

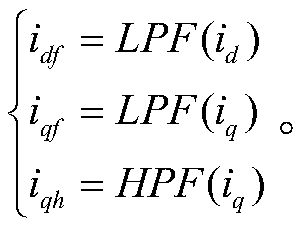

[0043] Step 1. Obtain the three-phase current i of the permanent magnet synchronous motor through the sampling of the AC current sensor na i nb and i nc , and then identify the angle according to the rotor position Use the 3s / 2r transformation of the rotating coordinate system to obtain i that contains DC components and high-frequency AC components d and i q , where i d and i q The DC component in the current is used for air gap flux linkage vector control, and the AC component is used for rotor position identification, including:

[0044] Step 1.1, the current i in the stationary three-phase coordinate system na i nb a...

Embodiment 2

[0064] A salient-pole three-phase permanent magnet synchronous motor is taken as an example to illustrate the implementation of the control method. The rated power of the motor is 87kW, the rated line voltage is 268V, the rated current is 201.5A, the rated speed is 810r / min, the number of pole pairs is 5, the stator resistance is 0.1Ω, the quadrature axis inductance is 367.5μH, the direct axis inductance is 285μH, and the salient pole ratio is 1.28.

[0065] Step 1. Obtain the three-phase current i of the permanent magnet synchronous motor through the sampling of the AC current sensor na i nb and i nc , using the position to identify the angle According to the transformation of the rotating coordinate system, the orthogonal and direct axis current i is obtained d and i q ; The cutoff frequencies of the low-order and high-order filters are both set to 5Hz, and the AC-D axis DC components for vector control are obtained.

[0066] Step 2, calculate the given motor voltage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com