A Design Method of Anti-cavitation Twisted Rudder

A design method and technology of twisting the rudder, applied in the direction of ship design, steering with rudder, ship construction, etc., can solve the problems of increasing vibration and noise, not taking into account the rotating wake of the propeller, increasing the load of the steering gear, etc., to achieve vibration excitation Force and radiation noise reduction, solving cavitation erosion problems, reducing time and area effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

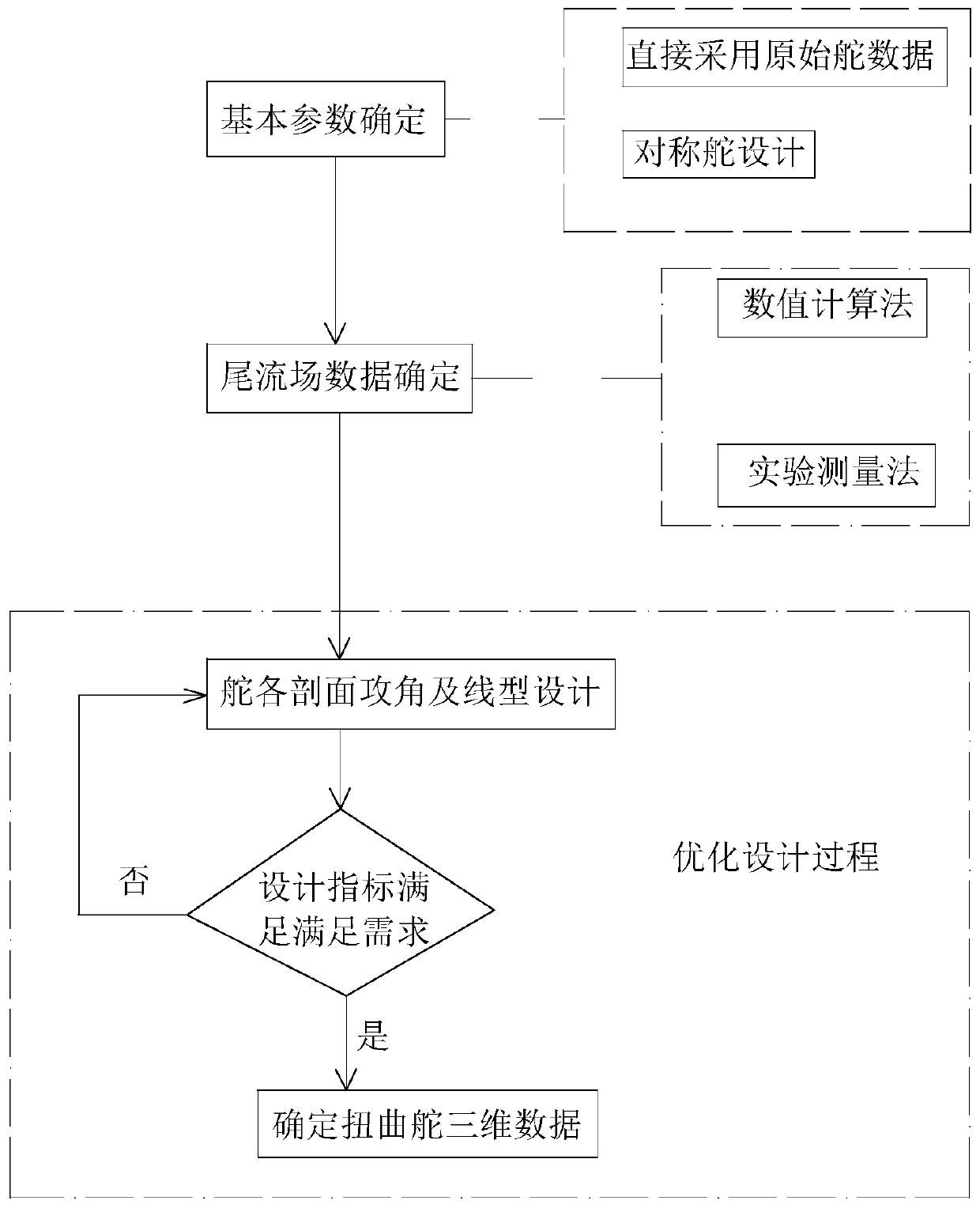

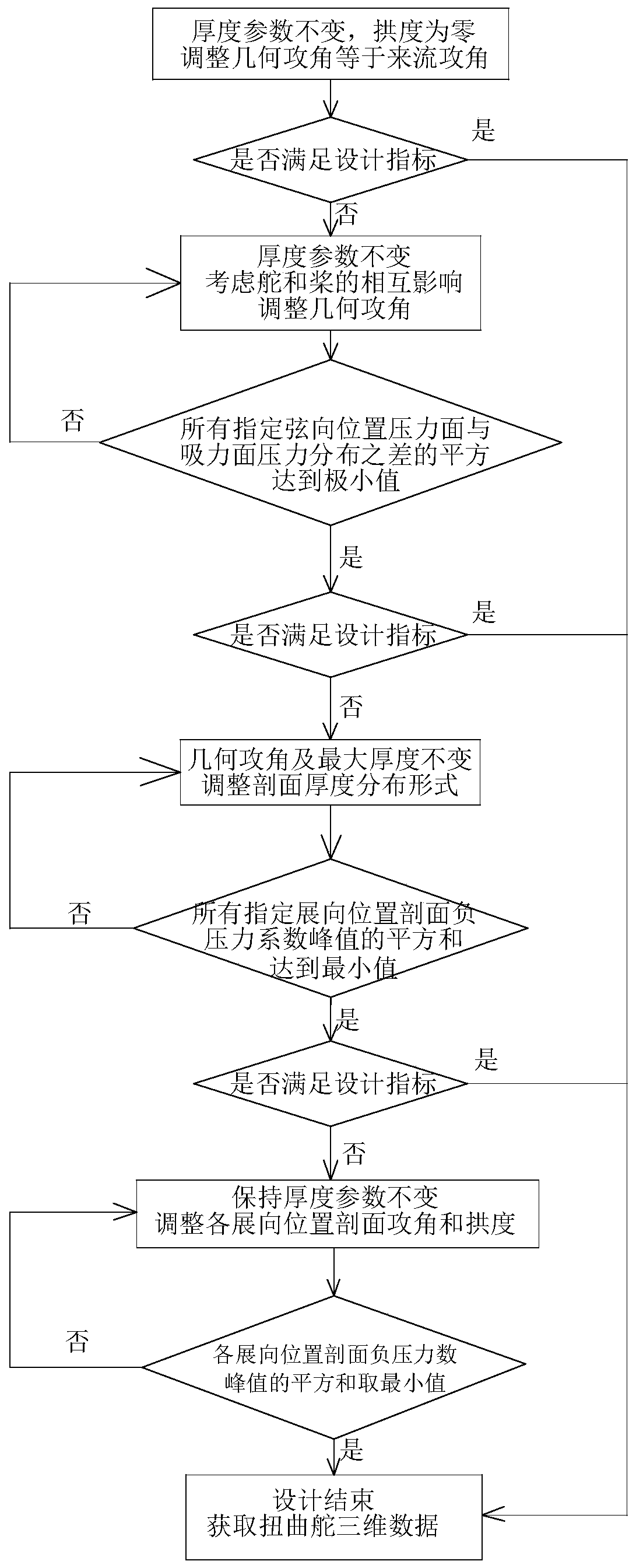

[0050] The anti-cavitation twisted rudder design method of the present invention will be described in detail below in conjunction with the specific design process, and the schematic flow chart of its design process is as follows figure 1 and figure 2 shown, including:

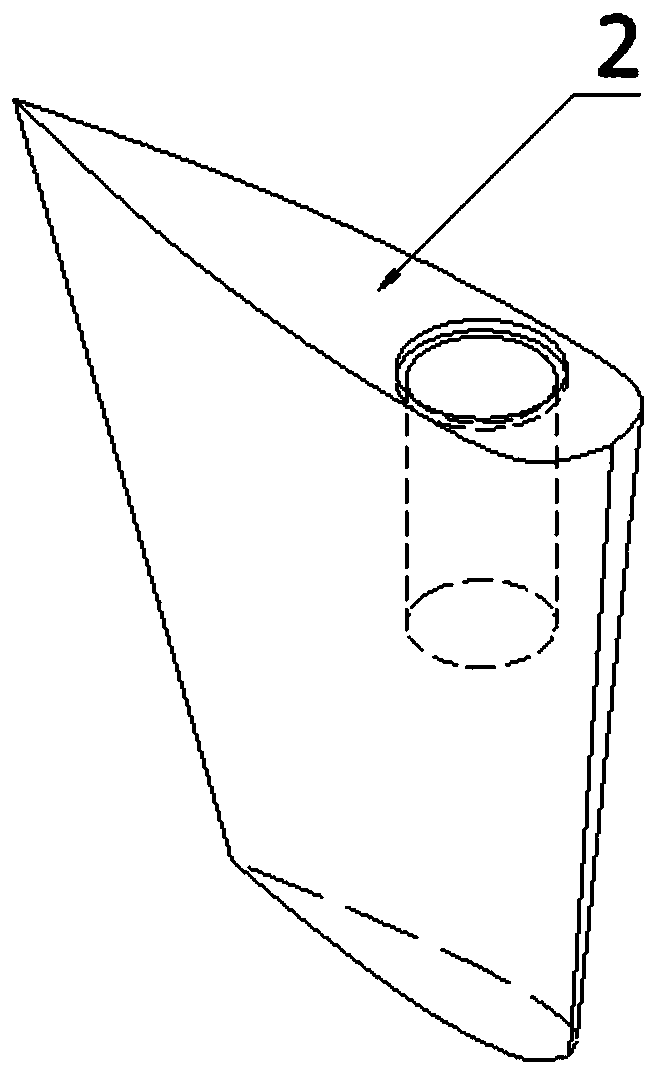

[0051] 1. Use the traditional symmetrical rudder design method to determine the rudder height of the target ship (such as Figure 14 middle L), the chord length of the section at each spanwise position, and the maximum thickness of the section at each spanwise position (such as Figure 16 Middle T), the line shape of each spanwise position section (including the distribution of thickness along the chord direction and the distribution of camber along the chord direction), and the installation position of the rudder shaft on the rudder.

[0052] In order to facilitate the operation, in this step, the geometric angle of attack of the sections at each spanwise position can be set to 0, and the linetype of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com